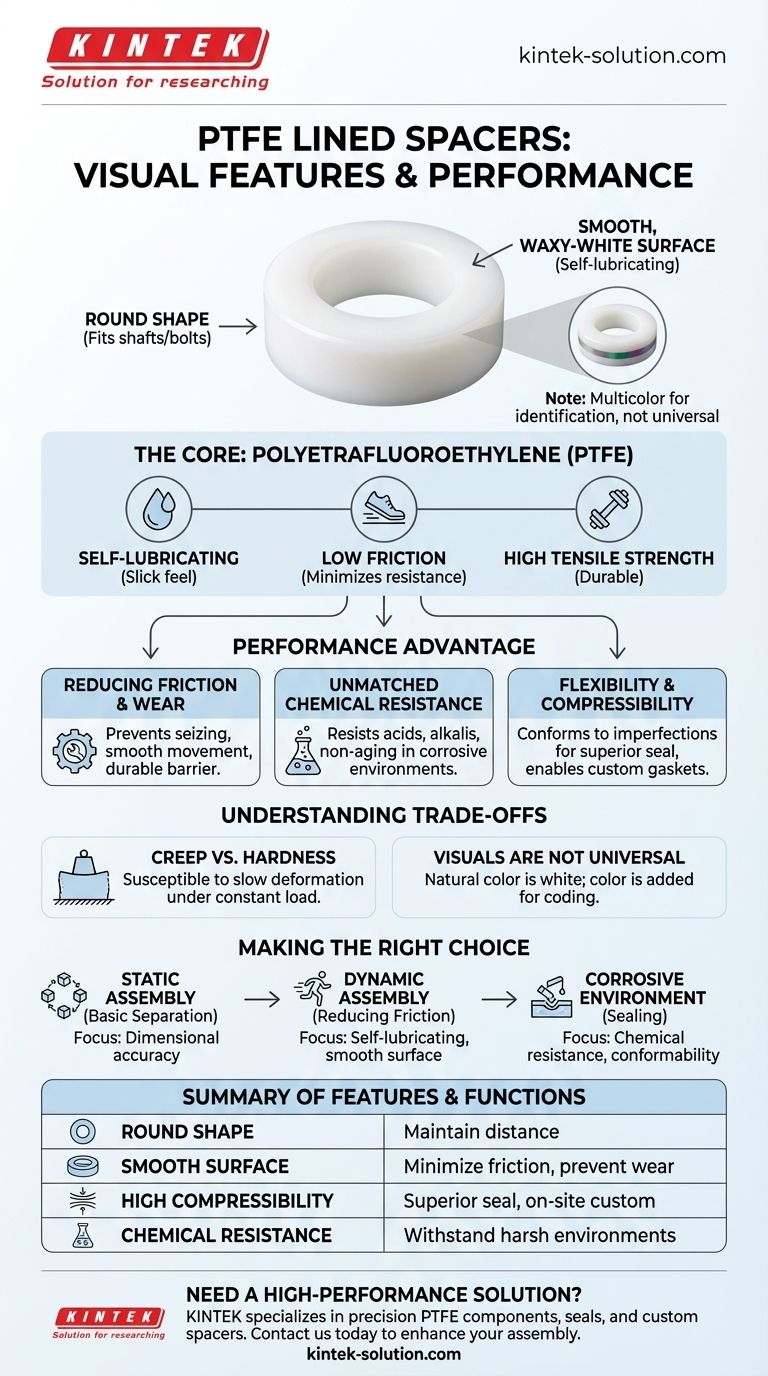

Visually, a PTFE Lined Spacer is primarily identified by its round shape and smooth surface. While some designs may feature a multicolor pattern for easier identification or branding, the most defining characteristic is its construction from Polytetrafluoroethylene (PTFE), which gives it a durable, often waxy-white appearance designed for high performance.

While its shape and color make it identifiable, the true significance of a PTFE spacer lies in its material properties. The smooth, self-lubricating surface is a direct result of the PTFE, which is chosen for its exceptional ability to reduce friction and resist chemical degradation.

Deconstructing the Design: Form Follows Function

The visual and physical characteristics of a PTFE spacer are not arbitrary; they are a direct result of the specific problems it is engineered to solve.

The Round Shape and Smooth Surface

A round shape is the most common form for spacers, as they are typically used to fit around shafts, bolts, or within cylindrical housings to maintain a specific distance between components.

The perfectly smooth surface is its most critical functional feature. This quality, combined with the material's inherent properties, is essential for its primary role in reducing friction and preventing wear.

The Core Material: Why PTFE?

PTFE, or Polytetrafluoroethylene, is a high-performance fluoropolymer. Its selection is based on a unique combination of properties that make it invaluable in demanding industrial and mechanical applications.

These properties include self-lubrication, an extremely low coefficient of friction, and high tensile strength. This is why it feels "slick" to the touch and can operate without external lubricants.

The Performance Advantage in Application

The material chosen for the spacer dictates its performance. PTFE provides distinct advantages, particularly in the sealing industry.

Reducing Friction and Wear

The spacer's primary job is to create a low-friction barrier between moving parts. The self-lubricating nature of PTFE means it provides a smooth, durable surface that minimizes resistance and prevents components from seizing or wearing down over time.

Unmatched Chemical Resistance

PTFE is exceptionally resistant to acids, alkali corrosion, and other harsh chemicals. This "non-aging" property ensures it will not degrade or become brittle when exposed to corrosive environments where metals or other plastics would fail.

Flexibility and Compressibility

Unlike a rigid metal spacer, PTFE has a flexibility similar to dense cotton. This high compressibility allows it to conform to surface imperfections, creating a superior seal. It enables on-site customization of gaskets, eliminating the need for large inventories of pre-cut parts.

Understanding the Trade-offs

No material is perfect for every situation. Understanding the limitations of PTFE is crucial for proper application.

Creep vs. Hardness

The same flexibility that makes PTFE a great sealant means it can be susceptible to "creep," or slow deformation under a constant, heavy load. In applications requiring extreme structural rigidity, a metallic spacer might be more appropriate.

Visuals Are Not Universal

While one reference mentions a "multicolor design," this is not a universal standard. The natural color of PTFE is a milky white. Color is often added for product differentiation or to codify different sizes or grades, but it is not an inherent feature of the material itself.

Making the Right Choice for Your Goal

To select the correct component, match the spacer's features to your primary engineering challenge.

- If your primary focus is basic separation in a static assembly: The dimensional accuracy (diameter and thickness) is your main concern, and any stable material may suffice.

- If your primary focus is reducing friction in a dynamic assembly: The self-lubricating properties and smooth surface of a PTFE spacer are your most critical requirements.

- If your primary focus is sealing in a corrosive environment: The exceptional chemical resistance and conformability of PTFE make it a far superior choice over most elastomers or metals.

Ultimately, understanding that the visual and tactile features of a PTFE spacer are a direct reflection of its high-performance material is key to leveraging it effectively.

Summary Table:

| Feature | Function |

|---|---|

| Round Shape | Fits around shafts/bolts to maintain distance between components. |

| Smooth, Waxy-White Surface | Provides self-lubrication to minimize friction and prevent wear. |

| High Compressibility | Conforms to surfaces for a superior seal, allowing on-site customization. |

| Exceptional Chemical Resistance | Withstands harsh acids, alkalis, and corrosive environments. |

Need a high-performance spacer solution? KINTEK specializes in manufacturing precision PTFE components, including seals, liners, and custom spacers for the semiconductor, medical, and industrial sectors. Our expertise in custom fabrication ensures you get the exact part for your application, from prototypes to high-volume orders. Contact us today to discuss how our PTFE solutions can enhance your assembly's performance and durability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the advantages of polyester-filled PTFE? A Guide to Superior Wear & Load Performance

- What makes PTFE graphite packing suitable for high-temperature applications? Superior Heat Management for Demanding Seals

- What are PTFE Bellows seals and where are they commonly used? The Ultimate Guide to Corrosive Fluid Sealing

- Why are PTFE energized seals a preferred choice for aerospace engineers? Ensure Reliability in Extreme Conditions

- Why are PTFE gaskets suitable for food processing plants? Ensure Purity & Compliance

- How do PTFE ring gaskets benefit piston engines? Enhance Engine Reliability and Longevity

- What are the typical applications of PTFE bearing pads? Managing Movement in Bridges and Large Structures

- Why are Teflon bushings preferred in the aerospace industry? Achieve Lighter, More Reliable Aircraft Systems