Fundamentally, PTFE graphite packing thrives in high-temperature environments because it expertly combines the inherent heat resistance and chemical inertness of Polytetrafluoroethylene (PTFE) with the superior thermal conductivity of graphite. This powerful partnership allows the packing to efficiently dissipate frictional heat away from the sealing surface, preventing premature degradation and failure where pure PTFE alone would struggle.

The critical advantage of PTFE graphite packing isn't just that it withstands heat, but that it actively manages it. The addition of graphite creates a pathway for frictional heat to escape, preventing overheating at the dynamic sealing surface and dramatically extending the material's operational limits.

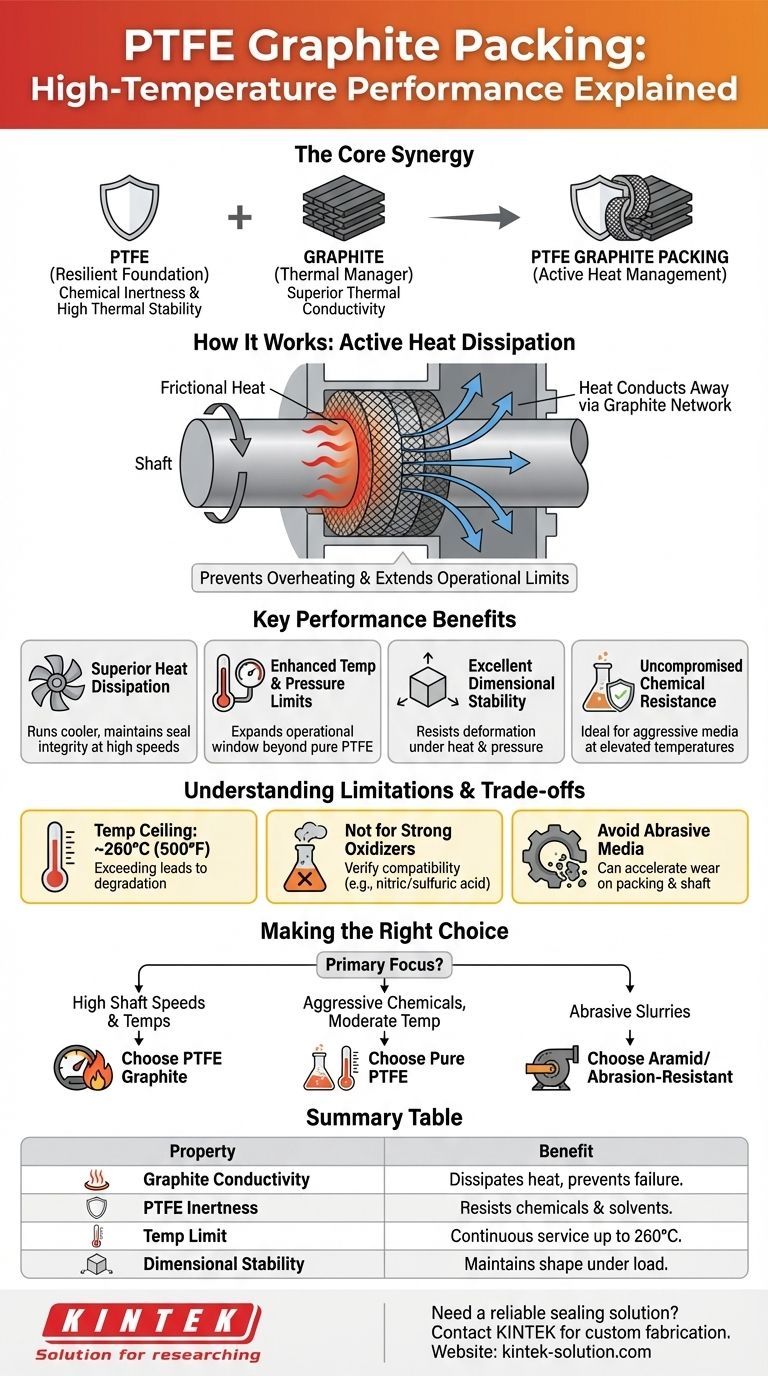

The Core Components: A Synergistic Partnership

To understand why this material excels, you must first appreciate the distinct roles played by its two primary components. They create a composite material that is far more capable than the sum of its parts.

The Role of PTFE: The Resilient Foundation

PTFE forms the backbone of the packing. It provides the essential characteristics that make it a viable sealing material in demanding industrial settings.

Its key contributions are its high thermal stability, with a melting point around 327°C (621°F), and its near-universal chemical inertness, resisting almost all industrial chemicals and solvents.

The Role of Graphite: The Thermal Manager

Graphite is not merely a filler; it is a functional additive that fundamentally changes the material's performance under load.

Its primary role is to provide excellent thermal conductivity. Graphite particles infused within the PTFE matrix act as a network to pull heat away from the high-friction point of contact (like a rotating shaft).

How They Work Together

In a dynamic application like a pump, the rotation of the shaft against the packing generates significant frictional heat.

With pure PTFE packing, this heat can become trapped at the sealing surface, causing the temperature to rise beyond PTFE's effective service limit. This can lead to glazing, hardening, and eventual seal failure.

The graphite in PTFE graphite packing creates a thermal bridge, conducting that damaging heat away from the shaft and into the equipment housing, where it can safely dissipate.

Key Performance Benefits in High-Heat Applications

This synergistic design translates directly into measurable performance advantages in the field, especially when high temperatures are a primary concern.

Superior Heat Dissipation

This is the material's defining characteristic. By actively managing and removing frictional heat, the packing runs cooler, lasts longer, and maintains its sealing integrity at higher shaft speeds.

Enhanced Temperature and Pressure Limits

Because heat is managed so effectively, the packing can be used at higher temperatures and pressures than pure PTFE. This expands its operational window, making it suitable for more demanding services.

Excellent Dimensional Stability

The composite material maintains its shape and strength even when exposed to high temperatures. This prevents the packing from deforming or extruding under pressure, ensuring a consistent and reliable seal.

Uncompromised Chemical Resistance

The addition of graphite does not negatively impact PTFE's legendary resistance to chemical attack. This makes the packing ideal for applications involving aggressive media at elevated temperatures, such as in chemical processing plants.

Understanding the Trade-offs and Limitations

No material is a universal solution. Being aware of the limitations of PTFE graphite packing is critical for proper application and avoiding premature failure.

The Absolute Temperature Ceiling

While excellent, this packing is not a refractory material. The practical continuous service temperature is typically rated around 260°C (500°F). Pushing the material beyond this limit can lead to degradation and loss of sealing properties.

Not for Strong Oxidizing Agents

Graphite can be attacked by strong oxidizing agents (like fuming nitric acid or hot sulfuric acid), especially at high temperatures. Always verify chemical compatibility for these specific, aggressive services.

Abrasive Media Can Cause Wear

PTFE graphite packing is designed for relatively clean fluid services. It is not recommended for heavy slurries or fluids containing abrasive particles, which can accelerate wear on both the packing and the equipment shaft.

Making the Right Choice for Your Application

Selecting the correct sealing material requires a clear understanding of your primary operational challenge.

- If your primary focus is high shaft speeds and elevated temperatures: PTFE graphite is an exceptional choice due to its ability to dissipate frictional heat and prevent thermal failure.

- If your primary focus is handling aggressive chemicals at moderate temperatures: Pure PTFE packing may be a sufficient and more cost-effective solution.

- If your primary focus is sealing abrasive slurries: An aramid fiber or other abrasion-resistant packing material would be a more appropriate choice.

Ultimately, selecting PTFE graphite packing is a strategic choice for managing thermal loads in demanding dynamic sealing applications.

Summary Table:

| Property | Benefit in High-Temperature Applications |

|---|---|

| Graphite Thermal Conductivity | Actively dissipates frictional heat, preventing seal failure. |

| PTFE Chemical Inertness | Resists almost all industrial chemicals and solvents. |

| Enhanced Temperature Limit | Suitable for continuous service up to 260°C (500°F). |

| Excellent Dimensional Stability | Maintains shape and seal integrity under heat and pressure. |

Need a reliable sealing solution for high-temperature or corrosive environments?

KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom packing seals. We serve the semiconductor, medical, laboratory, and industrial sectors, providing custom fabrication from prototypes to high-volume orders. Our expertise ensures you get a seal that actively manages heat and resists chemicals, maximizing your equipment's uptime and performance.

Contact KINTEK today to discuss your specific application requirements and get a quote for a sealing solution you can depend on.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries