To put it simply, PTFE gaskets are suitable for food processing plants because they are certified as food-safe by the FDA, they are chemically inert, and they can withstand the industry's demanding operational conditions. Their unique molecular structure prevents them from reacting with or sticking to food products, ensuring purity while also resisting the high temperatures and aggressive cleaning agents common in these environments.

The core reason for PTFE's success in food processing is not just its compliance with regulations, but its fundamental material properties. Its chemical inertness guarantees product purity, while its non-stick surface and thermal stability directly support the rigorous sanitation and production cycles required for food safety.

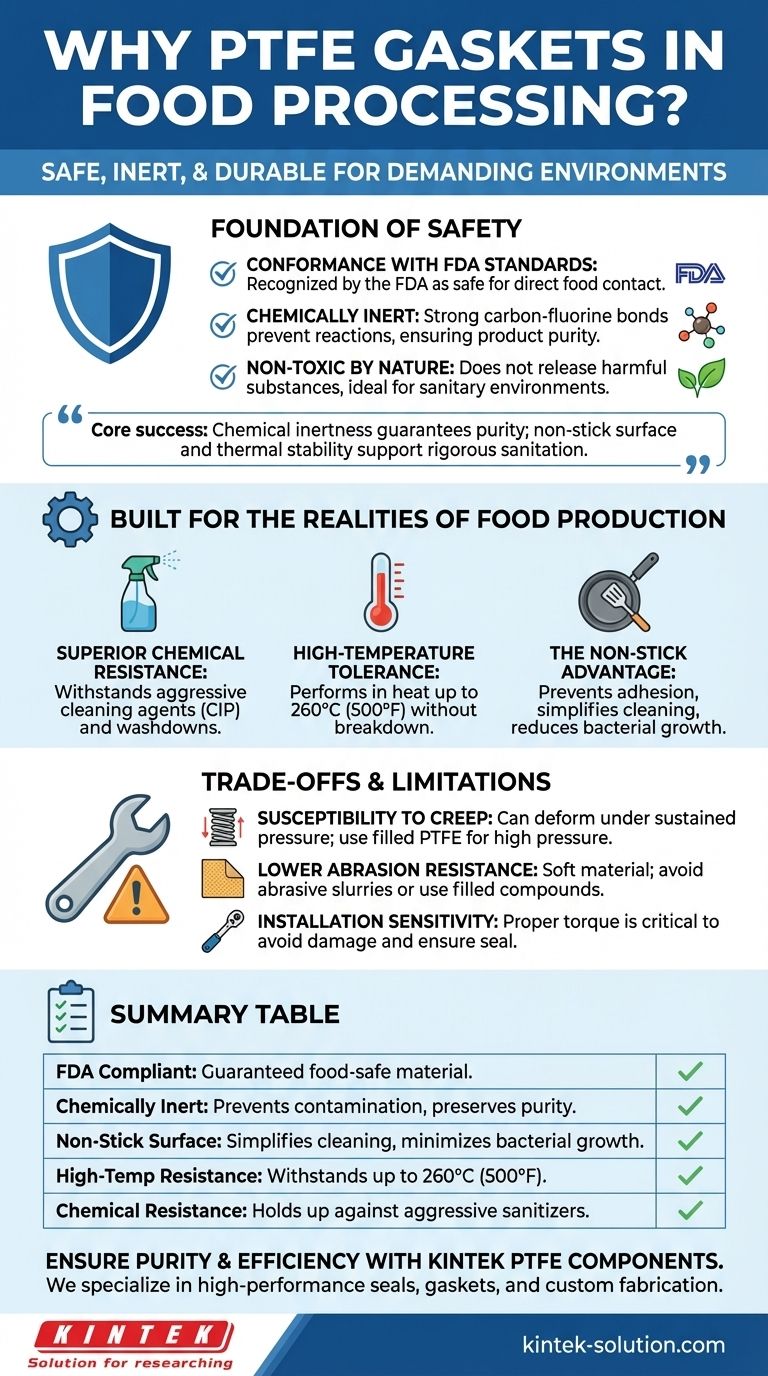

The Foundation of Safety: Compliance and Inertness

The primary concern in any food processing application is preventing contamination. PTFE's material composition makes it exceptionally well-suited to meet this fundamental requirement.

Conformance with FDA Standards

The most critical qualification for any material in direct contact with food is regulatory approval. PTFE is recognized by the Food and Drug Administration (FDA) as a safe material for these applications, providing a baseline assurance of its suitability.

A Truly Non-Reactive Material

PTFE, or polytetrafluoroethylene, has an extremely strong atomic structure of carbon and fluorine bonds. This structure makes the material chemically inert, meaning it will not react with or leach into food products, preserving their taste, quality, and purity.

Non-Toxic by Nature

This non-reactive quality also means PTFE is non-toxic. It doesn't release harmful substances, making it an ideal choice for sanitary environments where cleanliness and the absence of contaminants are paramount.

Built for the Realities of Food Production

Beyond its inherent safety, PTFE excels because it is durable enough to handle the demanding physical and chemical stresses of a modern food processing plant.

Superior Chemical Resistance

Food processing facilities rely on aggressive cleaning agents and sanitizers to maintain hygiene. PTFE is highly resistant to these harsh chemicals, ensuring gaskets and seals do not degrade during high-pressure washdowns or clean-in-place (CIP) cycles.

High-Temperature Tolerance

Many food processes, from cooking to sterilization, involve extreme heat. PTFE gaskets can reliably perform in temperatures up to 260°C (500°F), maintaining their structural integrity and sealing capability without breaking down.

The Non-Stick Advantage

PTFE's famous non-stick surface is a significant operational benefit. This property prevents food materials and other residues from adhering to the gasket, which drastically simplifies cleaning, reduces sanitation time, and minimizes the risk of bacterial growth.

Understanding the Trade-offs and Limitations

While PTFE is an exceptional material, no single solution is perfect for every application. Acknowledging its limitations is key to using it effectively.

Susceptibility to Creep

Under sustained mechanical pressure (like a bolted flange), PTFE can exhibit "creep" or "cold flow," slowly deforming over time. This can lead to a loss of sealing pressure. For high-pressure applications, filled PTFE grades (which include glass, carbon, or other materials) are often used to improve creep resistance.

Lower Abrasion Resistance

Compared to other polymers, pure PTFE is relatively soft and has lower resistance to abrasive media. If the process involves slurries or particulate matter, a more abrasion-resistant material or a filled PTFE compound might be a better choice.

Installation Sensitivity

PTFE gaskets are generally less forgiving than softer rubber elastomers. Proper installation and torque are critical to achieving a reliable, long-lasting seal without damaging the gasket. Over-tightening can accelerate creep and cause premature failure.

Making the Right Choice for Your Application

Selecting the correct sealing material requires matching its properties to your specific operational goal.

- If your primary focus is product purity and compliance: PTFE's FDA-approved, non-reactive, and non-toxic nature provides the highest level of assurance.

- If your primary focus is operational uptime and hygiene: Its resistance to aggressive cleaning agents and non-stick surface reduces downtime for sanitation and maintenance.

- If your primary focus is high-temperature processing: PTFE's ability to withstand continuous heat up to 260°C makes it a reliable choice for cooking and sterilization systems.

- If your primary focus is sealing high-pressure lines: You should evaluate filled PTFE variants that are specifically engineered to resist material creep.

Understanding these distinct properties allows you to confidently specify PTFE where it excels, ensuring both the safety of your product and the reliability of your process.

Summary Table:

| Key Property | Benefit for Food Processing |

|---|---|

| FDA Compliant | Guaranteed food-safe material, ensuring regulatory compliance. |

| Chemically Inert | Prevents contamination, preserving product taste and purity. |

| Non-Stick Surface | Simplifies cleaning, reduces downtime, and minimizes bacterial growth. |

| High-Temp Resistance | Withstands temperatures up to 260°C (500°F) for cooking/sterilization. |

| Chemical Resistance | Holds up against aggressive cleaning agents and sanitizers. |

Ensure the purity and efficiency of your food processing operations with precision-engineered PTFE components from KINTEK.

We specialize in manufacturing high-performance PTFE seals, gaskets, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our commitment to precision production and custom fabrication—from prototypes to high-volume orders—ensures you get a reliable, application-specific solution.

Ready to enhance your product safety and operational uptime? Contact our experts today to discuss your specific requirements and receive a custom solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments