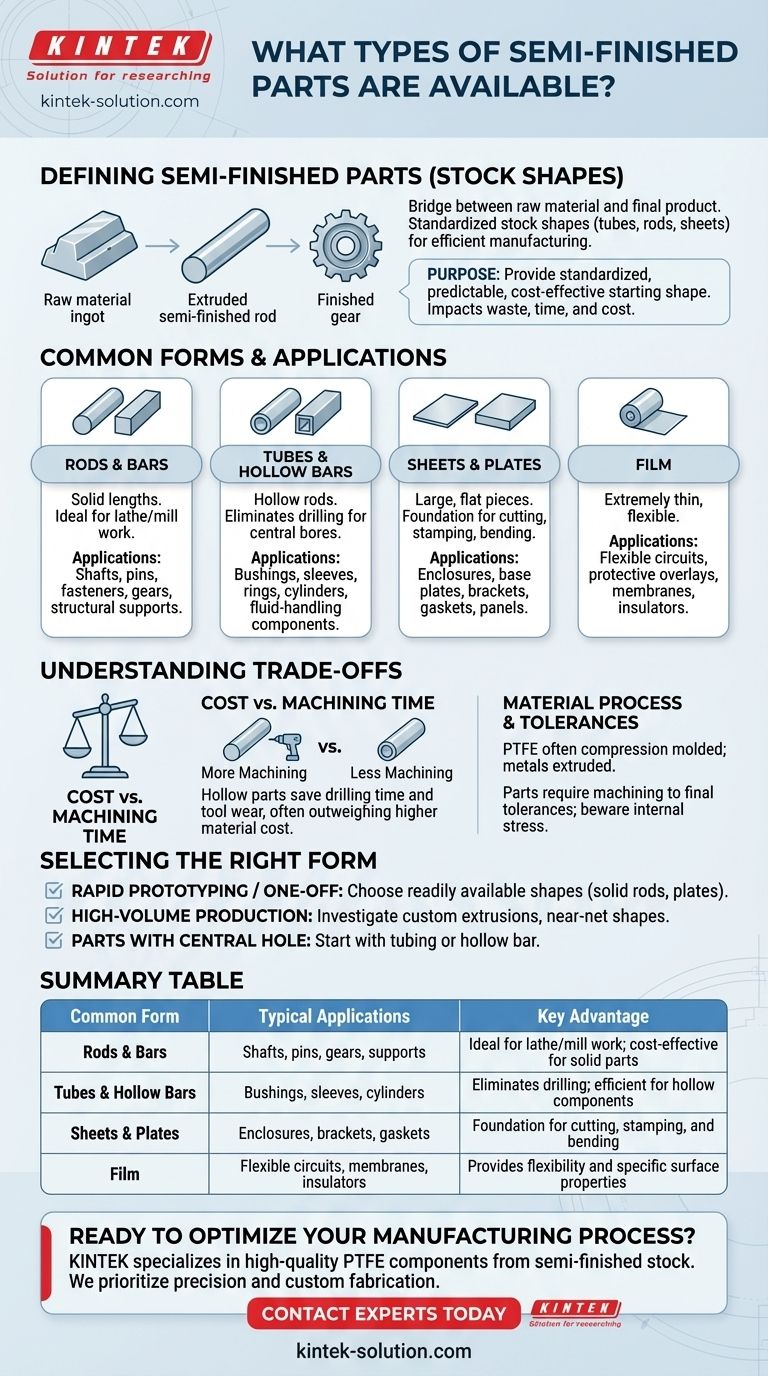

At its core, a semi-finished part is a standard stock shape of material—most commonly tubes, rods, sheets, plates, and films. These forms are created from raw materials through processes like extrusion or compression molding and serve as the starting point for producing a final, custom component through machining or other fabrication methods.

The primary purpose of a semi-finished part is to provide a standardized, predictable, and cost-effective starting shape for manufacturing. Selecting the form that is closest to your final product's geometry is a critical decision that directly impacts material waste, machining time, and overall project cost.

What Defines a Semi-Finished Part?

A semi-finished part, often called "stock shape" or "semi-finished stock," represents the bridge between raw material (like metal ingots or plastic resin) and a finished product. It is a material that has been processed into a basic, usable geometry but is not yet a functional component.

The Role in Manufacturing

These standardized shapes are the foundation of most subtractive manufacturing processes. Instead of starting with a rough, unpredictable block of material, engineers and machinists can rely on the consistent dimensions and material properties of a semi-finished part.

The Goal: Efficiency

Using a stock shape streamlines the entire production workflow. It simplifies quoting, material handling, and the setup of machinery, making the process faster and more repeatable.

Common Forms and Their Applications

While countless variations exist, most semi-finished parts fall into a few key categories, each optimized for different types of final components.

Rods and Bars

Rods (typically round) and bars (square, flat, or hexagonal) are solid lengths of material. They are the go-to choice for parts primarily produced on a lathe or a mill.

Typical applications include shafts, pins, fasteners, gears, and structural supports.

Tubes and Hollow Bars

Tubes are simply hollow rods. Starting with a tube is vastly more efficient than drilling a long hole through a solid rod if the final part requires a central bore.

This form is ideal for manufacturing bushings, sleeves, rings, cylinders, and fluid-handling components.

Sheets and Plates

Sheets (thinner) and plates (thicker) are large, flat pieces of material. They are the foundation for parts that are stamped, bent, laser cut, water-jet cut, or machined into flat profiles.

Common uses include equipment enclosures, base plates, mounting brackets, gaskets, and decorative panels.

Film

Film is an extremely thin sheet of material, often sold in rolls. Its applications rely on its flexibility, low thickness, and surface properties.

It is frequently used for flexible circuits, protective overlays, membranes, and high-performance insulators.

Understanding the Trade-offs

Choosing a semi-finished part is not just about the shape; it involves balancing cost, time, and material properties. The initial form you select has significant downstream consequences.

Cost vs. Machining Time

The most fundamental trade-off is between the upfront material cost and the subsequent machining effort.

A tube costs more per foot than a solid rod of the same outer diameter. However, for a hollow part, the savings in drilling time, tool wear, and material waste often make the tube the more economical choice overall.

Material and Manufacturing Process

The available stock shapes are often dictated by the material itself. For example, materials like PTFE are commonly formed into plates and rods using a compression process because their properties are not well-suited to other methods.

In contrast, many metals and thermoplastics are extruded, a process that is highly efficient for creating long, continuous profiles like rods and tubes.

Tolerances and Internal Stress

Semi-finished parts are not perfectly precise. They are manufactured to standard tolerances, meaning you must always plan to machine all critical surfaces to achieve your final dimensions.

Furthermore, processes like extrusion can introduce internal stresses into the material, which may cause the part to warp during machining if not handled with proper techniques.

Selecting the Right Form for Your Project

Making an informed decision on your starting material shape will save significant time and resources.

- If your primary focus is rapid prototyping or one-off parts: Choose readily available, simple shapes like solid rods and plates to minimize material lead time and initial cost.

- If your primary focus is high-volume production: Investigate custom extrusions or near-net shapes that minimize machining cycles and material scrap for each part.

- If your primary focus is any part with a central hole: Start with tubing or hollow bar to eliminate the time-consuming and wasteful process of drilling.

Ultimately, choosing the right semi-finished part accelerates your path from raw material to a precise, functional component.

Summary Table:

| Common Form | Typical Applications | Key Advantage |

|---|---|---|

| Rods & Bars | Shafts, pins, gears, supports | Ideal for lathe/mill work; cost-effective for solid parts |

| Tubes & Hollow Bars | Bushings, sleeves, cylinders | Eliminates drilling; efficient for hollow components |

| Sheets & Plates | Enclosures, brackets, gaskets | Foundation for cutting, stamping, and bending |

| Film | Flexible circuits, membranes, insulators | Provides flexibility and specific surface properties |

Ready to Optimize Your Manufacturing Process?

Choosing the right semi-finished part is the first step toward an efficient and cost-effective production run. KINTEK specializes in manufacturing high-quality PTFE components (seals, liners, labware, etc.) from semi-finished stock for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision and offer custom fabrication from prototypes to high-volume orders, helping you minimize waste and reduce machining time.

Let's discuss your project requirements and material needs. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F