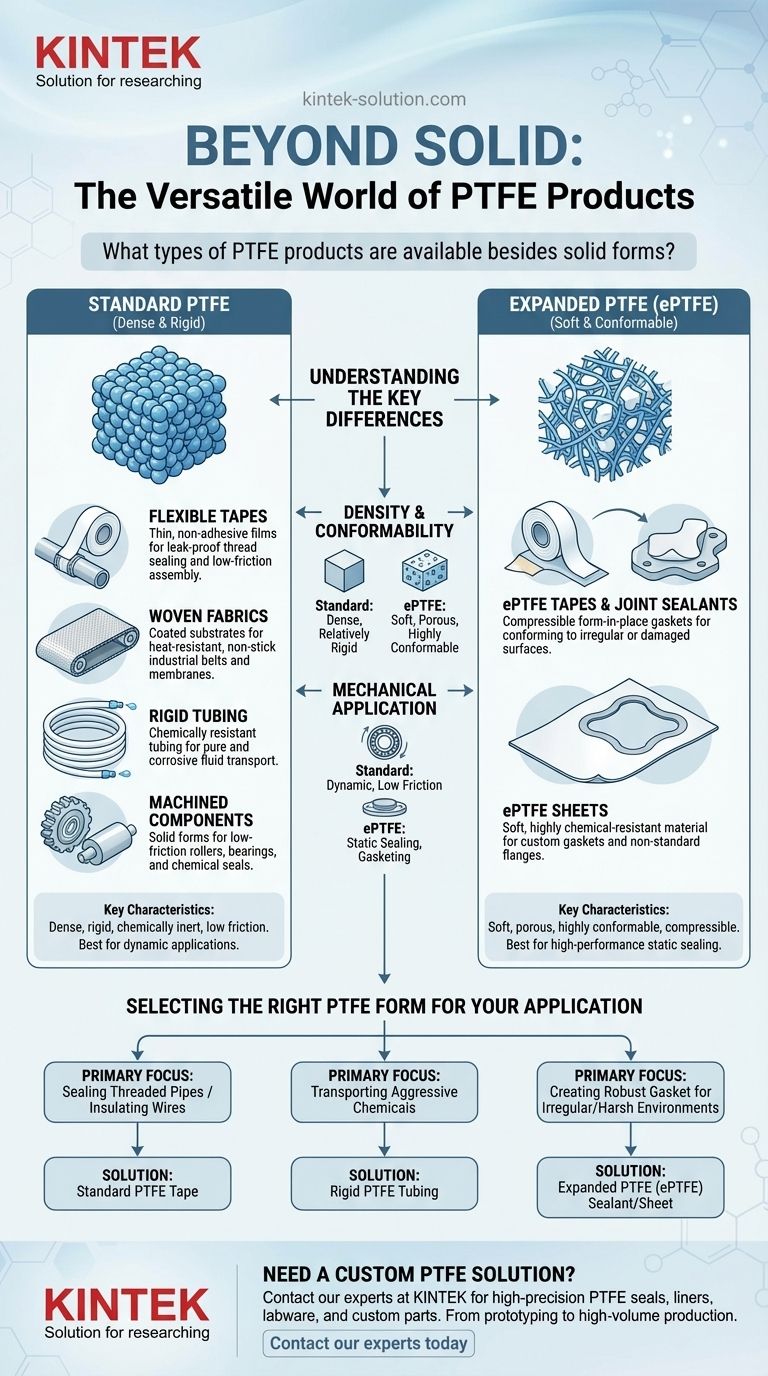

Beyond solid blocks and machined parts, Polytetrafluoroethylene (PTFE) is a highly versatile material available in numerous specialized forms. These include flexible tapes, woven fabrics, and hollow tubing, as well as a distinct category of "expanded" PTFE products designed for high-performance sealing applications.

The various forms of PTFE are not interchangeable; each is engineered to leverage the material's core properties—like chemical inertness and low friction—for a specific mechanical or industrial purpose, from thread sealing and fluid transport to creating conformable gaskets for complex surfaces.

Standard PTFE Product Forms

Standard, or virgin, PTFE is a dense, non-porous polymer. The products derived from it are designed to capitalize on its exceptional slipperiness, chemical resistance, and dielectric strength.

Flexible Tapes

PTFE tapes are thin, non-adhesive films. They are most commonly used for sealing pipe threads, where the material's low friction and malleability allow it to create a tight, leak-proof seal that can be easily disassembled later.

Woven Fabrics

PTFE can be coated onto a substrate like fiberglass to create a durable, non-stick, and heat-resistant fabric. These materials are often used in industrial applications such as conveyor belts for food processing or as architectural membranes.

Rigid Tubing

Because of its near-universal chemical resistance, PTFE is manufactured into tubing for transporting highly corrosive or pure fluids. Its low-friction surface also helps maintain consistent flow and prevents residue buildup.

Machined Components

This category includes the solid forms many engineers are familiar with. Due to its unique properties, PTFE is frequently machined into finished parts like low-friction rollers, chemically resistant seals, and high-performance seal rings.

The Role of Expanded PTFE (ePTFE)

Expanded PTFE, or ePTFE, is a fundamentally different material. It is created by rapidly stretching standard PTFE, which introduces a microporous structure of strong fibers and voids, making it soft and highly conformable.

ePTFE Tapes and Joint Sealants

Unlike standard tape, ePTFE tape and joint sealant are soft, compressible materials with an adhesive backing. They are used as a form-in-place gasket, conforming perfectly to irregular, scratched, or damaged flange surfaces to create a superior seal.

ePTFE Sheets

Expanded PTFE is also available in large sheets. These are used for die-cutting custom gaskets for non-standard flanges or applications where a soft, highly chemical-resistant sealing material is required.

Understanding the Key Differences

Choosing the correct form of PTFE requires understanding the trade-offs between the standard and expanded versions.

Density and Conformability

Standard PTFE is a dense, relatively rigid material. Expanded PTFE is soft, porous, and highly conformable, allowing it to compress and fill surface imperfections under load.

Mechanical Application

Standard PTFE excels in dynamic applications where low friction is paramount, such as in bearings, rollers, or non-stick surfaces. Expanded PTFE is designed almost exclusively for high-performance static sealing and gasketing.

Selecting the Right PTFE Form for Your Application

Your choice depends entirely on the engineering problem you need to solve.

- If your primary focus is sealing threaded pipes or insulating wires: Standard PTFE tape is the direct, cost-effective solution.

- If your primary focus is transporting aggressive chemicals: Rigid PTFE tubing provides the necessary chemical inertness and purity.

- If your primary focus is creating a robust gasket for irregular or chemically harsh environments: Expanded PTFE (ePTFE) in sealant or sheet form is the correct choice.

Ultimately, understanding whether your application requires low friction or compressible sealing is the key to selecting the right PTFE product.

Summary Table:

| PTFE Type | Key Characteristics | Common Applications |

|---|---|---|

| Standard PTFE | Dense, rigid, chemically inert, low friction | Thread sealing tape, chemical tubing, non-stick surfaces |

| Expanded PTFE (ePTFE) | Soft, porous, highly conformable, compressible | Form-in-place gaskets, sealing irregular flanges |

Need a custom PTFE solution for your application?

Whether you require standard PTFE components or specialized expanded PTFE (ePTFE) seals, KINTEK has the expertise to deliver. We manufacture high-precision PTFE products—including seals, liners, labware, and custom fabricated parts—for the semiconductor, medical, laboratory, and industrial sectors.

From prototyping to high-volume production, we ensure your parts meet exact specifications for chemical resistance, low friction, or superior sealing performance.

Contact our experts today to discuss your project requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- How does Teflon coating benefit cookware? Achieve Effortless Cooking and Easy Cleanup

- What are the material properties of PTFE? Master Extreme Performance for Demanding Applications

- What are the common grades of PTFE and their properties? Choose the Right Grade for Your Application

- What are the dielectric properties of PTFE products? Ensure Stable, High-Performance Electrical Insulation

- How is Teflon used in the textile industry? Creating Stain-Resistant, Water-Repellent Fabrics

- How does PTFE contribute to semiconductor manufacturing? Ensure Purity and Prevent Contamination

- What is the chemical composition of PTFE? Unlocking the Power of Carbon-Fluorine Bonds

- What are some key facts about Teflon/PTFE? The Ultimate Guide to Its Unique Properties and Applications