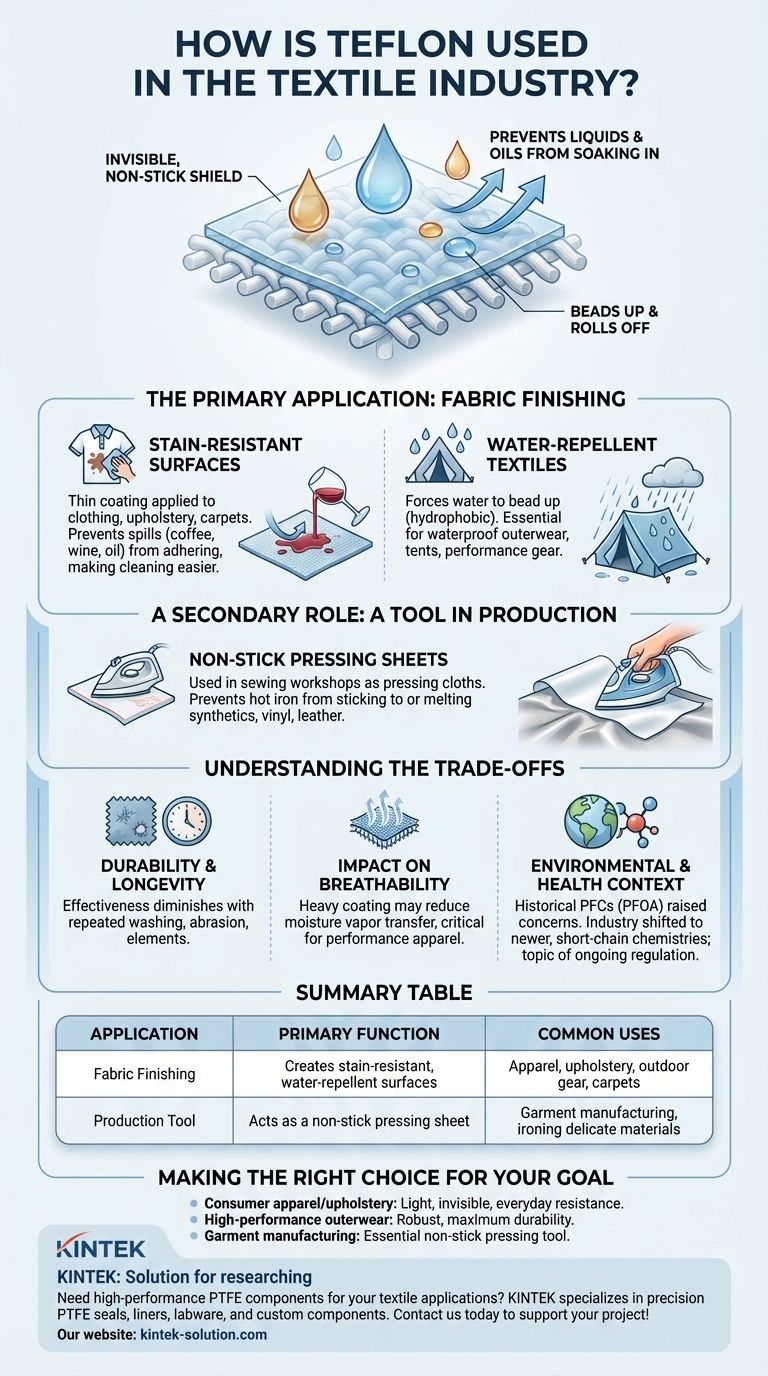

In the textile industry, Teflon is primarily used as a finish or coating applied directly to fabrics. This treatment transforms ordinary textiles into materials that are highly resistant to stains and water.

The core function of Teflon in textiles is to create an invisible, non-stick shield around the fabric's fibers. This low-friction surface prevents liquids and oils from soaking in, causing them to bead up and roll off instead.

The Primary Application: Fabric Finishing

The most common use of Teflon in textiles is as a topical finish, often applied at the mill after the fabric has been dyed. This process imparts valuable performance characteristics without significantly changing the fabric's look or feel.

Creating Stain-Resistant Surfaces

A thin Teflon coating is applied to clothing, upholstery, and carpets to make them stain-resistant.

This non-stick property prevents common spills like coffee, wine, or oil from adhering to the material, making cleaning significantly easier and more effective.

Engineering Water-Repellent Textiles

The same principle used for stain resistance is also highly effective at repelling water.

Fabrics treated with Teflon are hydrophobic, meaning they force water to form beads on the surface rather than being absorbed. This is essential for creating waterproof or water-repellent outerwear, tents, and other performance gear.

A Secondary Role: A Tool in Production

Beyond treating the final fabric, Teflon also plays a role as a tool during the garment manufacturing process.

Non-Stick Pressing Sheets

In sewing workshops, Teflon sheets are used as pressing cloths when ironing.

Placing a sheet between the iron and the fabric prevents the hot surface from sticking to or melting delicate synthetics, vinyl, or leather, protecting the material during construction.

Understanding the Trade-offs

While highly effective, applying a Teflon finish is not without considerations. Understanding these is key to evaluating its suitability for a given application.

Durability and Longevity

The coating's effectiveness can diminish over time. Repeated washing, abrasion, and exposure to the elements can slowly wear away the finish, reducing its stain- and water-repellent properties.

Impact on Breathability

While modern application methods are designed to coat individual fibers without sealing the fabric, a heavy coating can potentially reduce a textile's natural breathability. This is a critical factor for performance apparel, where moisture vapor transfer is essential.

Environmental and Health Context

Teflon is a brand name for PTFE, which belongs to a larger class of chemicals known as PFCs. Historical formulations (like PFOA) raised significant environmental and health concerns. The industry has largely shifted to newer, short-chain chemistries to mitigate these issues, but it remains a topic of ongoing discussion and regulation.

Making the Right Choice for Your Goal

The application of Teflon in textiles is tailored to the final product's intended use.

- If your primary focus is consumer apparel and upholstery: The goal is a light, invisible coating that provides everyday stain resistance without altering the fabric's hand feel.

- If your primary focus is high-performance outerwear: The application will be more robust, prioritizing maximum water repellency and durability for demanding outdoor conditions.

- If your primary focus is garment manufacturing: The use shifts from a fabric treatment to an essential tool, like a non-stick pressing sheet, for working with sensitive materials.

Ultimately, Teflon's unique non-stick properties provide a versatile and effective solution for both protecting and producing modern textiles.

Summary Table:

| Application | Primary Function | Common Uses |

|---|---|---|

| Fabric Finishing | Creates stain-resistant, water-repellent surfaces | Apparel, upholstery, outdoor gear, carpets |

| Production Tool | Acts as a non-stick pressing sheet | Garment manufacturing, ironing delicate materials |

Need high-performance PTFE components for your textile applications? KINTEK specializes in manufacturing precision PTFE seals, liners, labware, and custom components for the textile, semiconductor, medical, and industrial sectors. Whether you require prototypes or high-volume orders, our expertise ensures durable, non-stick solutions tailored to your needs. Contact us today to discuss how we can support your project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry