At its core, Polytetrafluoroethylene (PTFE), commonly known by the brand name Teflon, is a synthetic fluoropolymer thermoplastic valued for its unique combination of properties. It is chemically inert, has an extremely low coefficient of friction giving it a non-stick quality, and maintains its stability across a wide range of temperatures.

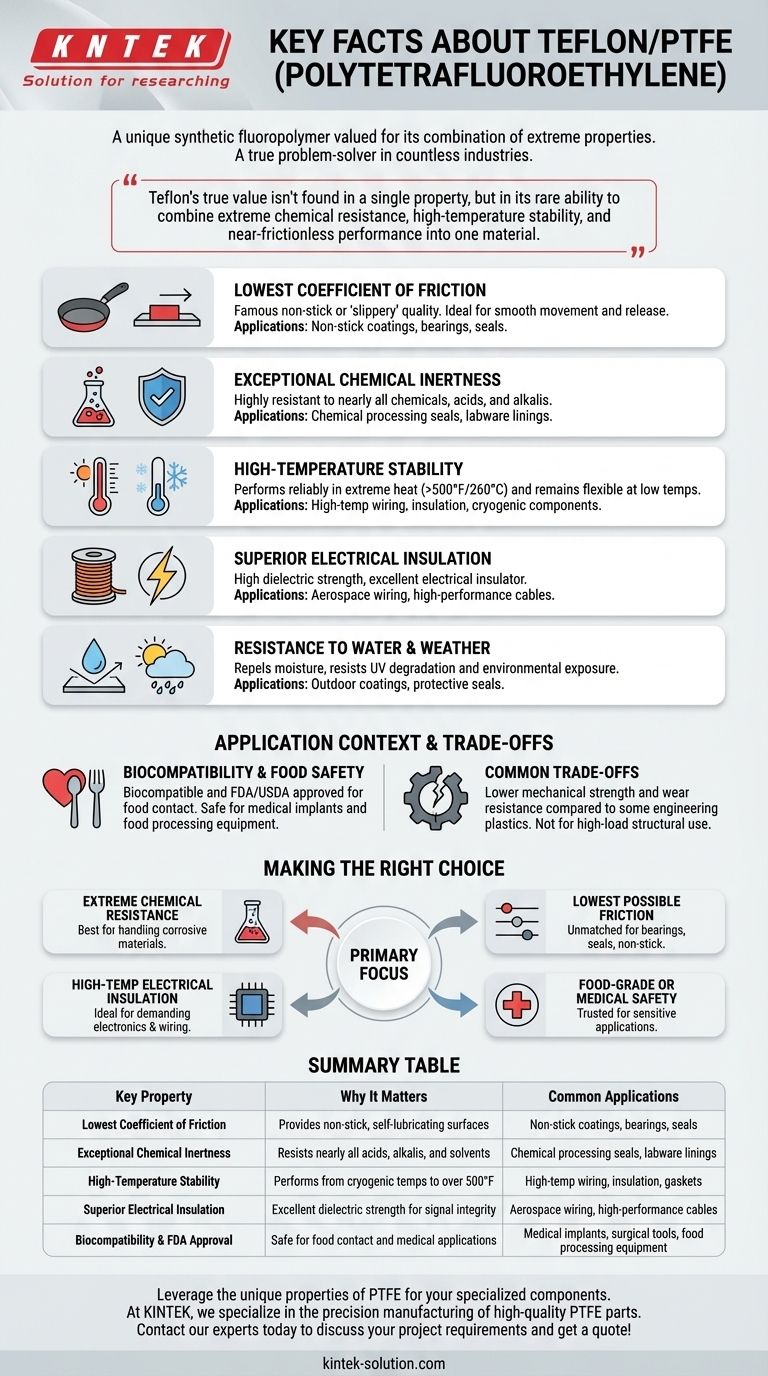

Teflon's true value isn't found in a single property, but in its rare ability to combine extreme chemical resistance, high-temperature stability, and near-frictionless performance into one material, making it an indispensable problem-solver in countless industries.

Core Material Properties Explained

Teflon was accidentally discovered in 1938 by a chemist who found a waxy, slippery white solid inside a gas bottle. This unexpected material possessed a set of characteristics that made it uniquely valuable.

The Lowest Coefficient of Friction

PTFE boasts one of the lowest friction coefficients of any known solid material. This is the source of its famous non-stick or "slippery" quality.

This property is critical for applications where smooth movement and release are necessary, from non-stick cookware to low-friction coatings on industrial machinery parts.

Exceptional Chemical Inertness

Teflon is highly resistant to nearly all chemicals, including powerful acids and alkalis.

This chemical inertness makes it an ideal material for seals, gaskets, and linings used in corrosive environments, such as chemical processing plants and laboratory equipment.

High-Temperature Stability and Flexibility

PTFE can withstand a vast range of temperatures, performing reliably in extreme heat and maintaining its flexibility even at very low temperatures.

This thermal stability ensures its integrity in applications from high-temperature wiring insulation to cryogenic components. It is also nonflammable.

Superior Electrical Insulation

Teflon possesses a high dielectric strength, meaning it is an excellent electrical insulator.

This property makes it a preferred material for insulating high-performance wires and cables, especially in aerospace and computer applications where signal integrity is paramount.

Resistance to Water and Weather

PTFE has an extremely low water absorption rate, effectively repelling moisture. Combined with its excellent weathering properties, it resists degradation from UV radiation and environmental exposure.

This makes it highly durable for outdoor applications, including architectural coatings and protective seals.

Understanding the Material's Application Context

While its core properties are impressive, its value is best understood through its certifications and practical trade-offs.

Biocompatibility and Food Safety

Teflon is biocompatible, meaning it is not harmful to living tissue, and is frequently used in the medical industry for implants and surgical tools.

Crucially, it is also FDA approved and USDA certified for use in food handling equipment, confirming its safety for cookware and food processing machinery.

Common Pitfalls and Trade-offs

While its properties are exceptional, PTFE is not a universal solution. It has a relatively lower mechanical strength and wear resistance compared to some other engineering plastics.

This means it may not be suitable for high-load structural applications where hardness and rigidity are the primary requirements. Its unique properties can also make it more challenging to process and manufacture than common plastics.

Making the Right Choice for Your Goal

Selecting PTFE depends entirely on whether its specific strengths align with your primary engineering challenge.

- If your primary focus is extreme chemical resistance: PTFE is one of the best choices available for handling corrosive materials.

- If your primary focus is the lowest possible friction: Its non-stick, self-lubricating surface is nearly unmatched for bearings, seals, and non-stick coatings.

- If your primary focus is high-temperature electrical insulation: Its dielectric strength and thermal stability make it ideal for demanding electronics and wiring.

- If your primary focus is food-grade or medical safety: Its FDA approval and biocompatibility make it a trusted material for sensitive applications.

Ultimately, Teflon's legacy is that of a specialized material that solves problems other materials simply cannot.

Summary Table:

| Key Property | Why It Matters | Common Applications |

|---|---|---|

| Lowest Coefficient of Friction | Provides non-stick, self-lubricating surfaces | Non-stick coatings, bearings, seals |

| Exceptional Chemical Inertness | Resists nearly all acids, alkalis, and solvents | Chemical processing seals, labware linings |

| High-Temperature Stability | Performs from cryogenic temps to over 500°F (260°C) | High-temp wiring, insulation, gaskets |

| Superior Electrical Insulation | Excellent dielectric strength for signal integrity | Aerospace wiring, high-performance cables |

| Biocompatibility & FDA Approval | Safe for food contact and medical applications | Medical implants, surgical tools, food processing equipment |

Leverage the unique properties of PTFE for your specialized components. At KINTEK, we specialize in the precision manufacturing of high-quality PTFE parts—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume production, our expertise ensures your components meet the highest standards for chemical resistance, thermal stability, and performance. Contact our experts today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the common characteristics of Teflon? Unlocking Extreme Chemical and Thermal Resistance

- In which industries is PTFE commonly used? Key Applications for Chemical & Thermal Resistance

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- What are some exceptional properties of PTFE? Unlock Unmatched Performance in Extreme Environments