The primary benefit of Teflon coating is its ability to create an exceptionally non-stick surface on cookware. This property, rooted in its unique chemical structure, fundamentally simplifies the cooking process by preventing food from adhering to the pan, which in turn makes cleanup significantly easier and reduces the need for cooking oils.

Teflon's value in the kitchen comes from its remarkably low-friction surface, which enhances cooking convenience and promotes healthier, low-fat preparation. However, this benefit is balanced by critical limitations in heat tolerance and physical durability that every user must understand.

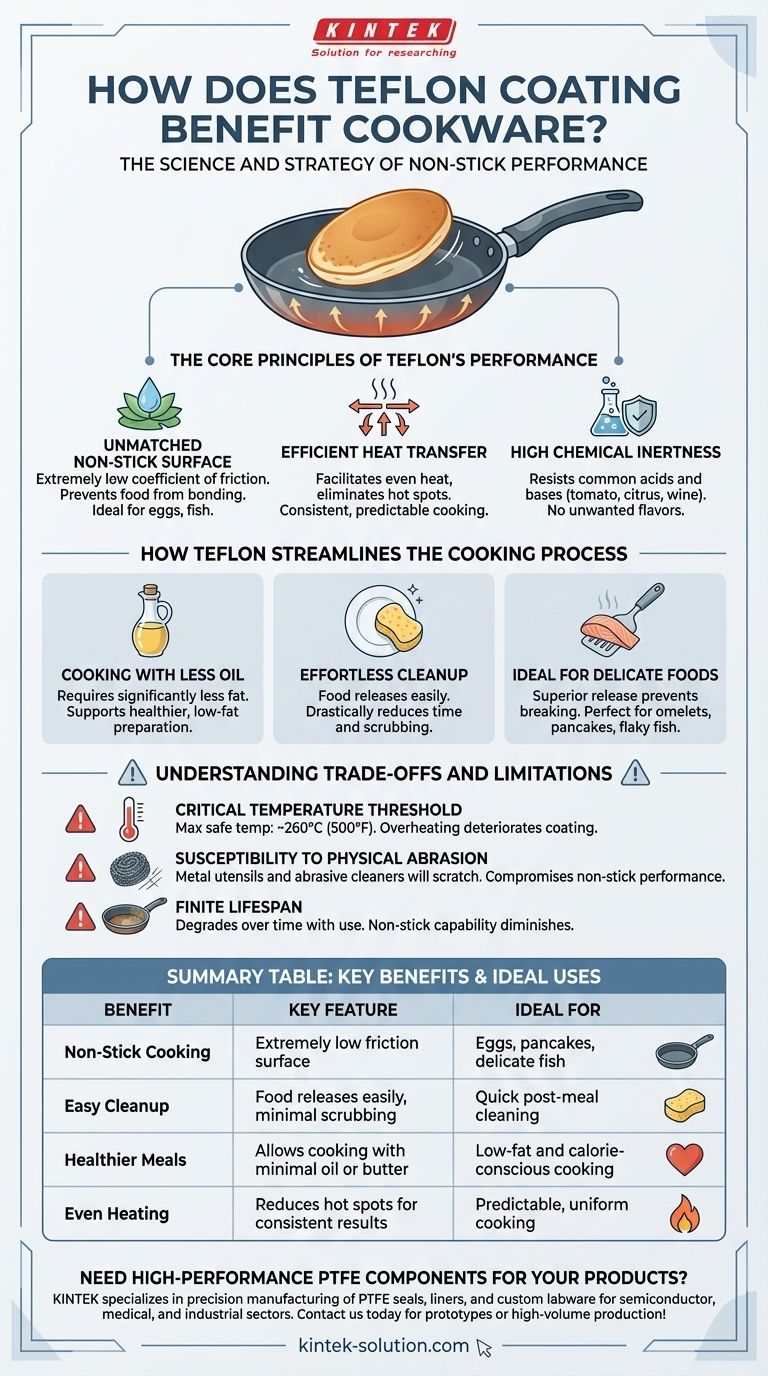

The Core Principles of Teflon's Performance

To appreciate its benefits, it's essential to understand the properties that make Teflon (scientifically known as Polytetrafluoroethylene or PTFE) so effective in a kitchen environment.

The Unmatched Non-Stick Surface

The defining characteristic of Teflon is its extremely low coefficient of friction. This means very few things stick to it.

This slickness prevents food proteins and carbohydrates from forming a chemical bond with the pan's surface during heating, which is why even delicate foods like eggs or fish release so easily.

Efficient Heat Transfer

Teflon coating facilitates efficient and even heat transfer from the pan to the food.

This helps to eliminate hot spots, reducing the risk of scorching some parts of a dish while others remain undercooked. The result is more consistent and predictable cooking.

High Chemical Inertness

Teflon is a highly stable and non-reactive material.

It resists damage from common acids and bases found in food, such as tomato sauce, citrus juices, or wine. This chemical inertness ensures the coating doesn't degrade or impart unwanted flavors when you cook with these ingredients.

Understanding the Trade-offs and Limitations

No material is perfect, and the convenience of Teflon comes with specific operational boundaries. Acknowledging these is key to using it safely and effectively.

The Critical Temperature Threshold

Teflon has a maximum recommended temperature for safe use, typically around 260°C (500°F).

Heating a pan beyond this point can cause the coating to begin deteriorating. While the material itself is non-toxic, it's crucial to avoid overheating to preserve the integrity of the cookware and maintain a safe cooking environment.

Susceptibility to Physical Abrasion

The non-stick surface, while chemically robust, is physically soft.

Using metal utensils, steel wool, or harsh abrasive cleaners will scratch and chip the coating. This physical damage permanently compromises its non-stick performance and shortens the lifespan of the cookware.

Finite Lifespan

Even with perfect care, a Teflon coating will degrade gradually over time through the cumulative stress of heating cycles and regular use. Its non-stick capability will diminish, signaling that it is time to replace the pan.

How Teflon Streamlines the Cooking Process

The scientific properties of Teflon translate directly into tangible benefits that simplify daily kitchen tasks.

Cooking with Less Oil

Because food doesn't stick, Teflon allows you to cook with significantly less butter or oil. This is a major benefit for those focused on low-fat cooking and reducing overall calorie intake.

Effortless Cleanup

The most celebrated benefit is the ease of cleaning. Food residue and sauces wipe away with minimal effort, drastically cutting down on the time and labor spent scrubbing pots and pans after a meal.

Ideal for Delicate Foods

The superior food release makes Teflon cookware the go-to choice for delicate items. Foods like pancakes, omelets, and flaky fish can be cooked perfectly without breaking apart or sticking to the pan.

Making the Right Choice for Your Goal

Understanding Teflon's profile allows you to use it where it excels and choose other materials when necessary.

- If your primary focus is convenience and low-fat cooking: Teflon is an unparalleled choice for its non-stick ease, simple cleanup, and minimal oil requirement.

- If your primary focus is high-heat searing (e.g., steaks): You should be mindful of the temperature limits and consider cast iron or stainless steel, which are better suited for extreme heat.

- If your primary focus is maximizing lifespan: Commit to using only wood, silicone, or plastic utensils and hand-washing with a soft sponge to protect the coating from abrasion.

By appreciating both its powerful benefits and its clear limitations, you can use Teflon cookware effectively to make your time in the kitchen more efficient and enjoyable.

Summary Table:

| Benefit | Key Feature | Ideal For |

|---|---|---|

| Non-Stick Cooking | Extremely low friction surface | Eggs, pancakes, delicate fish |

| Easy Cleanup | Food releases easily, minimal scrubbing | Quick post-meal cleaning |

| Healthier Meals | Allows cooking with minimal oil or butter | Low-fat and calorie-conscious cooking |

| Even Heating | Reduces hot spots for consistent results | Predictable, uniform cooking |

Need high-performance PTFE components for your products? KINTEK specializes in precision manufacturing of PTFE seals, liners, and custom labware for the semiconductor, medical, and industrial sectors. Whether you require prototypes or high-volume production, our expertise ensures superior non-stick, chemically inert solutions tailored to your needs. Contact us today to discuss your project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance