At their core, PTFE ferromagnetic support discs are compatible with virtually any grinding or polishing machine that utilizes a magnetic platen system. Their design is not specific to a single brand, allowing them to be used as a versatile component across equipment from various manufacturers in materials preparation labs.

The true value of these discs isn't just their broad equipment compatibility, but how their unique construction—a magnetic steel core bonded to a non-stick PTFE surface—fundamentally improves the efficiency and cleanliness of the sample preparation workflow.

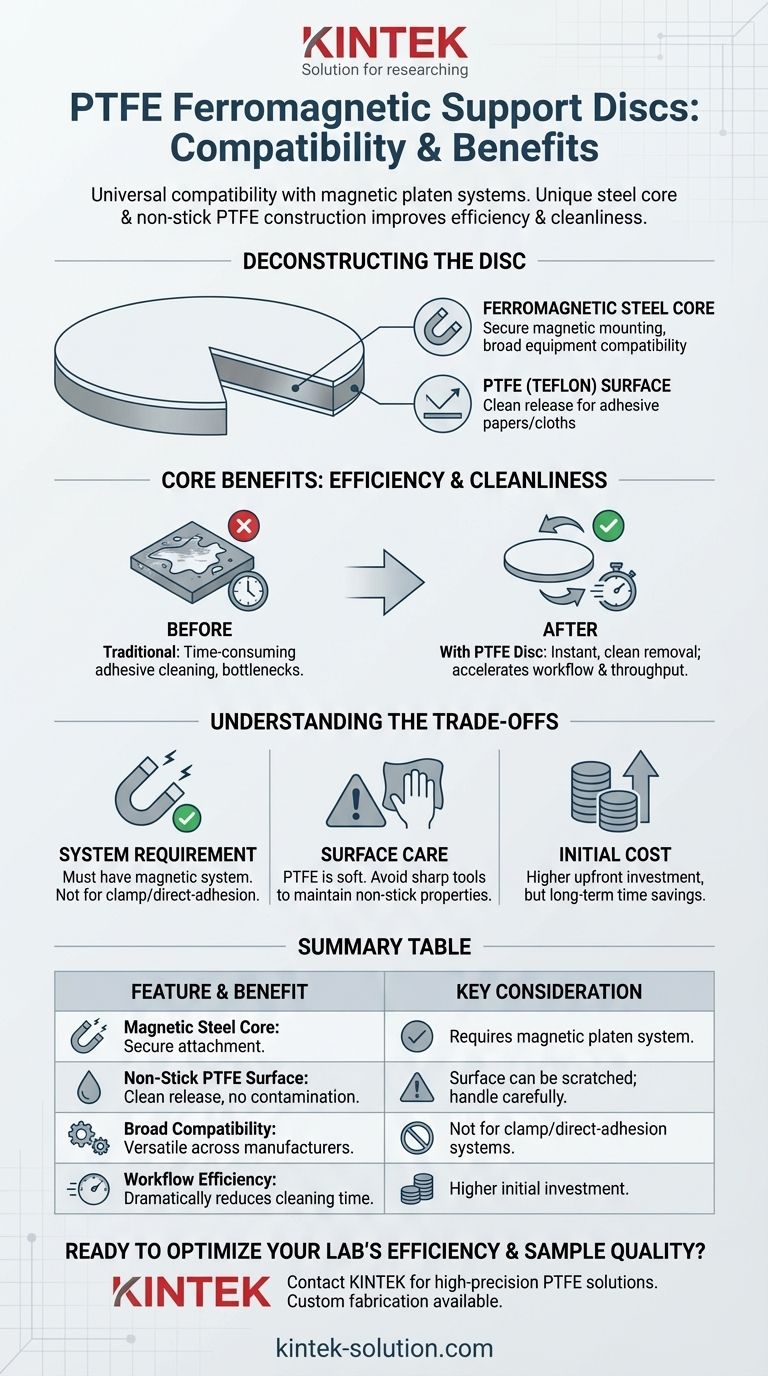

Deconstructing the Disc: How It Works

To understand the compatibility, it's essential to understand the disc's two primary components and their functions. These discs are a simple but effective combination of materials.

The Ferromagnetic Steel Core

The body of the disc is made from a rigid, ferromagnetic stainless steel. This is the "magnetic" part that allows the disc to securely attach to the rotating platen of a grinder or polisher equipped with a magnetic system.

This magnetic mounting is the key to its broad compatibility, as it's a standard system used by many equipment manufacturers.

The PTFE (Teflon) Surface

The working surface of the disc is a layer of Polytetrafluoroethylene (PTFE), commonly known by the brand name Teflon. This material provides the critical functional benefit.

Its non-stick nature is designed specifically for use with adhesive-backed grinding papers or polishing cloths.

The Core Benefit: Efficiency and Cleanliness

While compatible with many machines, the reason to choose these discs lies in the problems they solve during the sample preparation process.

Eliminating Adhesive Residue

The primary advantage is the clean release of consumables. The PTFE surface prevents the sticky adhesive from transferring from the abrasive paper or polishing cloth onto the support disc.

This eliminates the time-consuming step of cleaning adhesive residue off the platen between grits, a common source of workflow bottlenecks and potential sample contamination.

Accelerating Workflow

By enabling the instant, clean removal and replacement of abrasive or polishing surfaces, these discs significantly speed up the entire grinding and polishing sequence.

Technicians can move from one preparation step to the next without interruption, increasing lab throughput and ensuring a more consistent process.

Understanding the Trade-offs

While highly beneficial, these discs are a specialized tool with considerations to keep in mind.

System Requirement

The most critical limitation is that your grinder or polisher must have a magnetic system for mounting discs. They are not compatible with older or simpler machines that rely on clamps or direct-adhesion platens.

Surface Care

PTFE is a relatively soft material. While durable for its intended purpose, the surface can be scratched or gouged by sharp tools or improper handling.

Damage to the PTFE surface can compromise its non-stick properties, reducing the disc's effectiveness over time.

Initial Cost

These composite discs typically represent a higher upfront investment compared to a basic steel disc or using the machine's platen directly. The cost must be weighed against the long-term time savings and gains in process quality.

Making the Right Choice for Your Lab

Selecting the right support system depends entirely on your laboratory's priorities and goals.

- If your primary focus is high-throughput and efficiency: The time saved by eliminating adhesive cleaning makes these discs a clear and valuable investment.

- If your primary focus is preventing cross-contamination: The inert, non-stick PTFE surface is ideal for ensuring no residue is transferred between polishing stages or samples.

- If you are working with a variety of materials and grits: The ability to quickly swap discs pre-loaded with different abrasives can dramatically streamline your workflow.

Ultimately, choosing a PTFE ferromagnetic disc is a decision to optimize your process for cleanliness, speed, and consistency.

Summary Table:

| Feature | Benefit | Key Consideration |

|---|---|---|

| Magnetic Steel Core | Secure attachment to magnetic platens on various equipment brands. | Requires a machine with a magnetic platen system. |

| Non-Stick PTFE Surface | Clean release of adhesive-backed papers/cloths; prevents contamination. | Surface can be scratched; requires careful handling. |

| Broad Equipment Compatibility | Versatile use across many grinder/polisher manufacturers. | Not suitable for machines using clamp or direct-adhesion systems. |

| Workflow Efficiency | Dramatically reduces time spent cleaning adhesive residue between steps. | Higher initial investment compared to basic steel discs. |

Ready to eliminate adhesive residue and accelerate your sample preparation workflow?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including ferromagnetic support discs, for demanding applications in semiconductor, medical, laboratory, and industrial settings. Our discs are engineered to deliver the superior non-stick performance and magnetic hold you need for a cleaner, faster, and more consistent process.

We prioritize precision production and offer custom fabrication services, from prototypes to high-volume orders, to meet your exact specifications.

Contact KINTEK today to discuss how our PTFE solutions can optimize your lab's efficiency and sample quality.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- Why are PTFE-layered septa used in high-performance applications? Ensure Sample Integrity & Accuracy

- How should PTFE plugs be handled with corrosive liquids? Prevent Costly Glassware Damage

- What are PTFE lined caps made of? A Guide to Their Inert, Protective Construction

- What are the advantages of using PTFE laboratory bottles? Unmatched Chemical Resistance for Critical Samples

- What are the temperature ranges for PTFE-lined bottle caps? From -200°C to +250°C for Your Critical Applications

- What sizes and pore options are available for PTFE filters? Choose the Right Filter for Your Application

- What factors should be considered when selecting a PTFE-coated septum? Ensure Peak Performance and Data Integrity

- What are the key properties of PTFE that make it suitable for chromatography septums? Ensure Sample Integrity and Reliable Results