At its core, a PTFE-lined cap is a composite closure. The main body of the cap is typically made of a standard plastic (like polypropylene) or metal, which provides the structural integrity and threading. The critical component, however, is the separate inner liner, a thin disc made of PTFE (polytetrafluoroethylene), which is a highly inert synthetic fluoropolymer.

The purpose of a PTFE-lined cap is not just to close a container, but to create an exceptionally non-reactive barrier. This design combines a standard structural cap with a high-performance PTFE liner to protect sensitive contents from contamination and aggressive chemicals from damaging the closure.

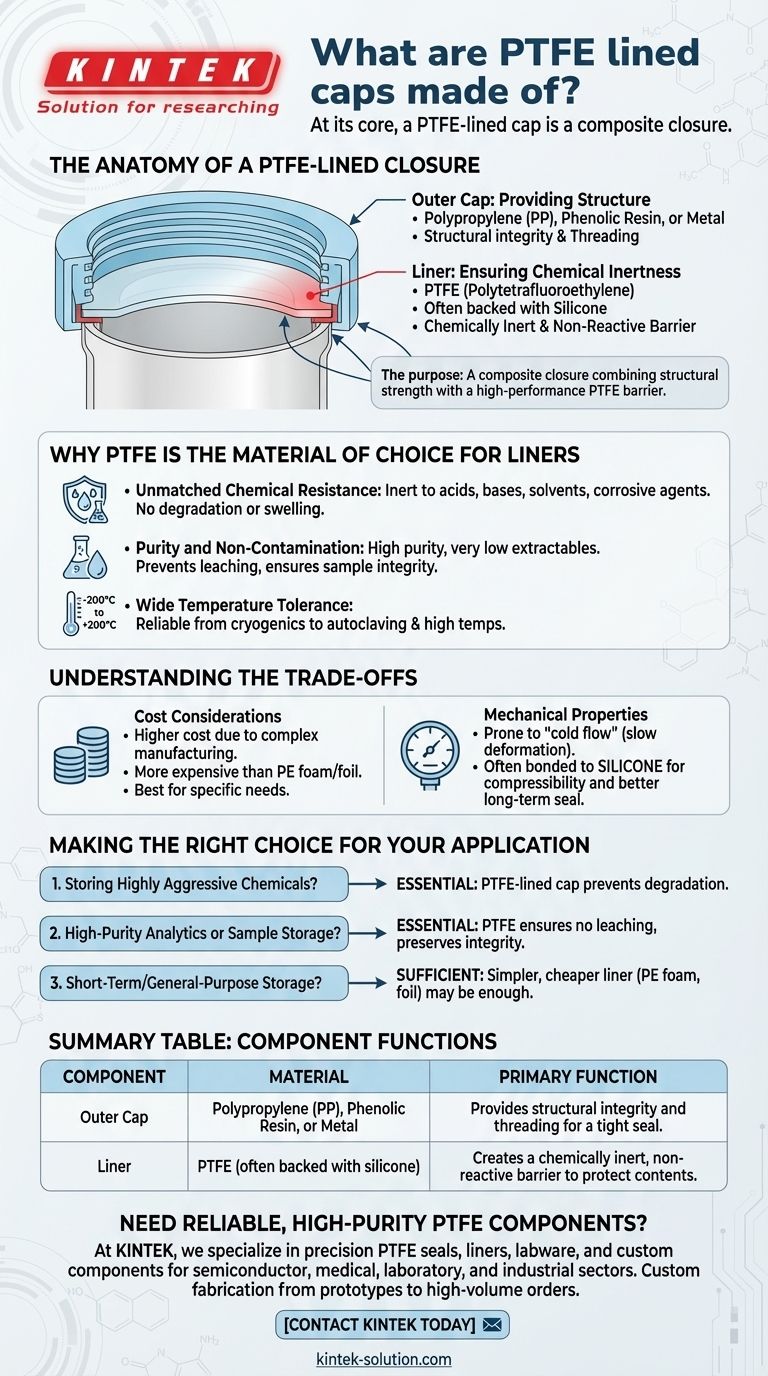

The Anatomy of a PTFE-Lined Closure

A PTFE-lined cap consists of two primary components, each serving a distinct and critical function. Understanding both is key to appreciating its value.

The Outer Cap: Providing Structure

The outer cap is the part you handle and twist. Its job is purely mechanical.

It is typically made from common, cost-effective materials like polypropylene (PP) or phenolic resin for plastic caps, or various metals for more specialized applications. This part provides the physical strength and the threads necessary to secure the cap to a container and create a tight seal.

The Liner: Ensuring Chemical Inertness

The liner is the heart of the system. This thin disc sits inside the cap and makes direct contact with the container's rim and, potentially, its contents.

This component is made of PTFE, the same material famous for its use in non-stick coatings. It is a fluoropolymer prized for its unique properties, which are essential for demanding scientific and industrial applications.

Why PTFE is the Material of Choice for Liners

The choice of PTFE is not arbitrary; it is selected for a combination of properties that make it superior for protecting high-purity or highly reactive substances.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert materials known. It is resistant to nearly all acids, bases, solvents, and other corrosive agents.

This ensures the liner itself does not degrade, swell, or fail when exposed to aggressive chemicals, maintaining the integrity of the seal over time.

Purity and Non-Contamination

For analytical and laboratory work, sample purity is paramount. PTFE is extremely pure and has a very low level of extractables.

This means it will not leach chemicals into the sample, which could skew analytical results. Its non-stick surface also prevents material from adhering to the liner, reducing the risk of cross-contamination between uses.

Wide Temperature Tolerance

PTFE performs reliably across a broad temperature spectrum, from cryogenic lows to highs well over 200°C (400°F).

This makes PTFE-lined caps suitable for a variety of processes, including autoclaving (steam sterilization), refrigeration, and storing materials at elevated temperatures.

Understanding the Trade-offs

While highly effective, PTFE-lined caps are not the default choice for every situation. Their benefits come with practical considerations.

Cost Considerations

PTFE is a high-performance polymer, and its manufacturing process is more complex than that of simpler plastics.

Consequently, PTFE-lined caps are more expensive than caps with more common liners, such as those made from polyethylene foam or foil. For general-purpose storage of non-reactive materials, a simpler liner is often more cost-effective.

Mechanical Properties

PTFE is a relatively soft material that can be prone to "cold flow," or slow deformation under sustained pressure.

To counteract this and improve resealing capability, PTFE is often bonded to a more resilient backing material, like silicone. This creates a composite liner where the PTFE provides chemical inertness and the silicone provides a compressible, elastic cushion for a more reliable, long-term seal.

Making the Right Choice for Your Application

Selecting the correct cap liner is a critical decision that directly impacts the integrity of your work.

- If your primary focus is storing highly aggressive chemicals: A PTFE-lined cap is essential to prevent degradation of the closure and contamination of the substance.

- If your primary focus is high-purity analytics or sample storage: The inertness of PTFE ensures that nothing will leach from the cap into your sample, preserving its integrity.

- If your primary focus is short-term or general-purpose storage of non-reactive materials: A simpler, less expensive cap liner (like PE foam or foil) may be sufficient and more economical.

Understanding the role of each material empowers you to select a closure system that guarantees the safety and purity of your work.

Summary Table:

| Component | Material | Primary Function |

|---|---|---|

| Outer Cap | Polypropylene (PP), Phenolic Resin, or Metal | Provides structural integrity and threading for a tight seal. |

| Liner | PTFE (Polytetrafluoroethylene), often backed with silicone | Creates a chemically inert, non-reactive barrier to protect contents. |

Need reliable, high-purity PTFE components for your critical applications?

At KINTEK, we specialize in the precision manufacturing of PTFE seals, liners, labware, and custom components. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures your materials are protected from contamination by aggressive chemicals.

We offer custom fabrication from prototypes to high-volume orders, guaranteeing the chemical resistance and purity your work demands.

Contact KINTEK today to discuss your specific needs and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the advantages of using PTFE stirrers and shafts in corrosive applications? Ensure Purity and Reliability

- Why are PTFE shovels considered cost-effective? Maximize ROI with Superior Durability

- How do Teflon membranes contribute to the accuracy and reliability of laboratory experiments? Ensure Purity and Precision

- What additional advantages does PTFE offer for laboratory use? Maximize Purity and Reliability

- What are the safety features of PTFE-lined bottle caps? Ensure Chemical Inertness and Sample Integrity

- Why are PTFE shovels considered biocompatible? Ensure Sample Purity and Safety

- How do Teflon membranes enhance chemical resistance in laboratory equipment? Maximize Purity and Durability

- In which industries are PTFE lined caps commonly used? Ensure Product Purity & Chemical Resistance