When selecting a PTFE-coated septum, you must evaluate its chemical compatibility, temperature stability, thickness, and resealing capability. It is also critical to ensure it is a physical match for your vial and appropriate for your specific analytical application, such as gas chromatography, to prevent contamination and sample loss.

The ideal septum is not merely a lid for your vial; it is a critical component of your analytical system. Its selection requires a careful balance of chemical, thermal, and mechanical properties to guarantee the integrity and accuracy of your results.

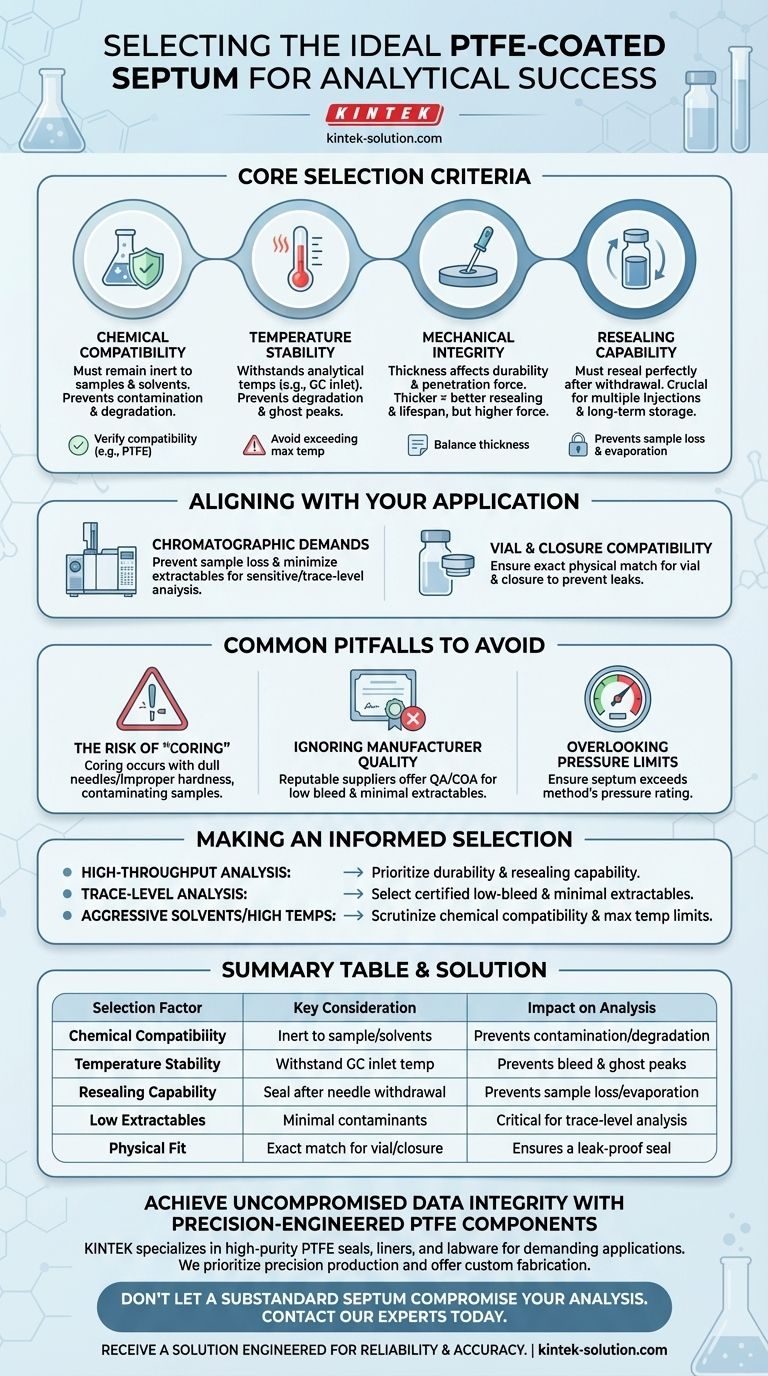

Analyzing the Core Selection Criteria

Choosing the correct septum is fundamental to preventing leaks, sample contamination, and instrument downtime. Each factor plays a distinct role in protecting the validity of your analysis.

Chemical Compatibility: The First Line of Defense

A septum must remain inert when in contact with your sample and solvents. Any chemical reaction can compromise the septum's physical integrity or introduce contaminants.

While PTFE (polytetrafluoroethylene) offers excellent resistance to a wide range of acids, bases, and organic solvents, you must always verify its compatibility with the specific chemicals in your workflow.

Temperature Stability: Preventing Degradation

Your septum must withstand the temperatures of your analytical process, particularly the inlet temperature in a gas chromatograph (GC).

Exceeding a septum's maximum operating temperature can cause it to degrade, leading to bleed—the release of volatile compounds that create ghost peaks and interfere with your analysis.

Mechanical Integrity: Thickness and Durability

The septum's thickness affects both its durability and how easily a needle can penetrate it.

A thicker septum generally offers better resealing and a longer lifespan for multiple injections. However, it also requires more force to pierce, which can increase the risk of needle bending.

Resealing Capability: Maintaining a Perfect Seal

The septum’s primary mechanical function is to reseal perfectly after the needle is withdrawn. A poor seal leads to sample evaporation and potential atmospheric contamination.

This self-sealing property is crucial for methods requiring multiple injections from the same vial or for long-term sample storage.

Aligning the Septum with Your Application

Beyond the core material properties, the septum must be suited for your specific instrument, vials, and analytical goals. An ideal septum for one method can be a significant source of error in another.

Chromatographic Demands

For sensitive techniques like gas chromatography (GC), a key consideration is preventing sample loss due to evaporation through the puncture site.

For ultra-sensitive or trace-level analyses, you must select a septum with minimal extractables and leachables. These are chemical contaminants that can migrate from the septum into your sample, creating analytical interference.

Vial and Closure Compatibility

A septum is part of a system that includes the vial and cap. An incorrect size or design will result in an improper seal.

Always ensure the septum's diameter and style are an exact match for your vial and closure system to prevent leaks and ensure consistent results.

Common Pitfalls to Avoid

Even a high-quality septum can fail if its limitations are not understood. Recognizing these potential issues is key to maintaining data integrity.

The Risk of "Coring"

Coring occurs when the needle punches out a small piece of the septum material, which can fall into the sample or clog the needle. This is more common with dull needles or improperly matched septum hardness.

Ignoring Manufacturer Quality

Reputable manufacturers provide crucial quality assurance, often including certificates of analysis that verify low bleed and minimal extractables.

Opting for products from established suppliers is a reliable way to ensure consistency, accuracy, and reproducibility in your work.

Overlooking Pressure Limits

While less common in standard chromatography, some applications involve pressure. Like any seal, a septum has a maximum pressure rating that should not be exceeded.

Making an Informed Selection

Your final choice should be a direct reflection of your primary analytical goal.

- If your primary focus is high-throughput analysis: Prioritize septa with proven durability and superior resealing capabilities to withstand repeated injections without failure.

- If your primary focus is trace-level or ultra-sensitive analysis: Select a septum specifically certified for low bleed and minimal extractables to prevent contamination of your sample.

- If your primary focus is working with aggressive solvents or high temperatures: Scrutinize the chemical compatibility charts and ensure the septum's maximum operating temperature exceeds your method's requirements.

Ultimately, treating the septum as a critical analytical variable is the first step toward achieving reliable and reproducible data.

Summary Table:

| Selection Factor | Key Consideration | Impact on Analysis |

|---|---|---|

| Chemical Compatibility | Must be inert to sample/solvents | Prevents contamination and degradation |

| Temperature Stability | Must withstand GC inlet temperature | Prevents septum bleed and ghost peaks |

| Resealing Capability | Must seal after needle withdrawal | Prevents sample loss and evaporation |

| Low Extractables | Minimal chemical contaminants | Critical for trace-level/sensitive analysis |

| Physical Fit | Exact match for vial and closure | Ensures a leak-proof seal |

Achieve Uncompromised Data Integrity with Precision-Engineered PTFE Components

Your analytical results depend on the quality of every component, especially the septum. KINTEK specializes in manufacturing high-purity PTFE seals, liners, and labware designed for the demanding environments of semiconductor, medical, laboratory, and industrial applications.

We prioritize precision production and offer custom fabrication—from prototypes to high-volume orders—to ensure a perfect fit and performance for your specific analytical system.

Don't let a substandard septum compromise your analysis. Contact our experts today to discuss your requirements and receive a solution engineered for reliability and accuracy.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications