At their core, PTFE laboratory bottles offer a trifecta of benefits unmatched by standard labware: near-universal chemical resistance, an exceptionally wide temperature tolerance, and superior physical properties. They are engineered for the most demanding applications where materials like glass or other plastics would corrode, melt, shatter, or contaminate the sample.

The decision to use a PTFE bottle is a decision for certainty. It is the material of choice when you cannot risk chemical reaction, thermal failure, or sample contamination, ensuring the integrity of your most critical laboratory work.

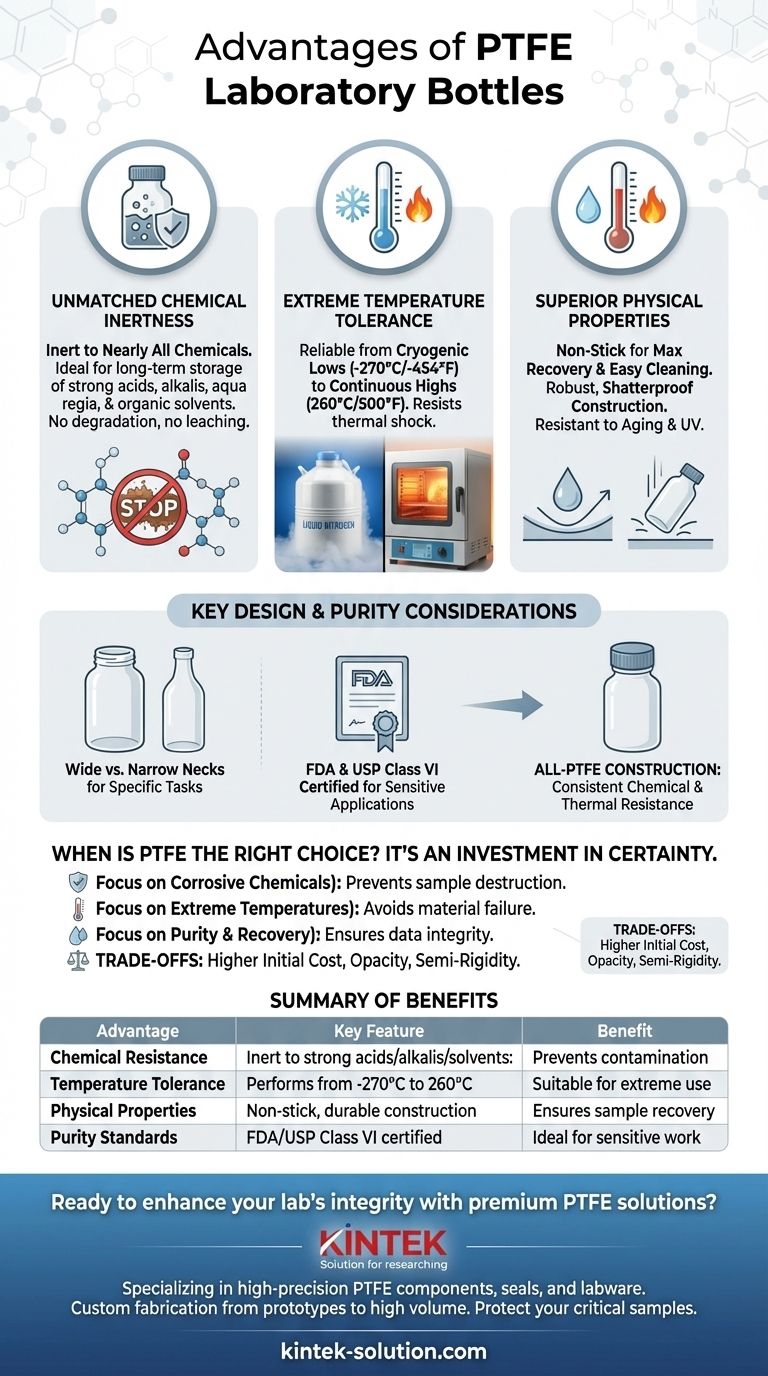

The Core Advantages of PTFE: A Deeper Look

To understand why PTFE is a premium material for labware, we must look beyond the surface at its fundamental characteristics. These properties work together to create a container that is both incredibly resilient and chemically non-reactive.

Unmatched Chemical Inertness

The primary advantage of PTFE is its remarkable resistance to chemical attack. The strong carbon-fluorine bonds in its structure make it inert to nearly all chemicals.

This means it is the ideal choice for long-term storage or aggressive reactions involving strong acids, alkalis, aqua regia, and a vast range of organic solvents. The bottle will not degrade, and more importantly, it will not leach impurities into your sample.

Extreme Temperature Tolerance

PTFE performs reliably across a vast spectrum of temperatures, a range that causes most other materials to fail.

It maintains its structural integrity and properties in applications from cryogenic lows of -270°C (-454°F) up to continuous working temperatures of 260°C (500°F). This makes it suitable for both deep-freeze storage and high-temperature digestions, without the risk of thermal shock that can shatter glass.

Superior Physical Properties

Beyond its chemical and thermal resistance, PTFE’s physical makeup provides distinct advantages for laboratory use.

Non-Stick Surface for Purity and Recovery

PTFE has one of the lowest coefficients of friction of any solid, giving it an exceptionally non-stick and smooth internal surface. This prevents valuable samples from adhering to the walls, ensuring complete recovery and making the bottles easy to clean thoroughly.

Robust and Durable Construction

PTFE bottles typically feature heavy wall construction, making them highly durable and shatterproof. Unlike glass, they can withstand drops and impacts. They are also resistant to aging, UV radiation, and embrittlement, ensuring a long service life.

Key Design and Purity Considerations

High-performance labware is defined by details that ensure reliability and prevent contamination.

All-PTFE Construction

Crucially, high-quality PTFE bottles include screw caps also made from PTFE. This ensures the entire system shares the same chemical and thermal resistance, creating a consistent, leak-free seal.

Certified for Sensitive Applications

Many PTFE lab bottles conform to stringent standards like FDA and USP Class VI requirements. This certification makes them suitable for high-purity, pharmaceutical, or biological applications where preventing contamination is paramount.

Wide vs. Narrow Neck Designs

These bottles are available in two main configurations to suit different tasks. Wide-neck bottles are easier to fill with powders or viscous liquids, while narrow-neck designs are better for pouring and minimizing evaporation.

Understanding the Trade-offs

No material is perfect for every situation. Being a trusted advisor means acknowledging the limitations.

Higher Initial Cost

PTFE is a premium, high-performance polymer. Its manufacturing process is more complex, resulting in a significantly higher cost compared to glass, polypropylene (PP), or high-density polyethylene (HDPE) bottles.

Opacity

PTFE is opaque, meaning you cannot visually inspect the contents or volume without opening the bottle. This can be a drawback for experiments where visual monitoring is necessary.

Rigidity

While durable, PTFE is a semi-rigid plastic, not a rigid solid like glass. This flexibility can be an advantage in preventing breakage, but it may not be suitable for applications requiring absolute structural rigidity.

When is PTFE the Right Choice?

Choosing the correct labware is fundamental to successful and repeatable science. PTFE is an investment reserved for work where failure is not an option.

- If your primary focus is working with highly corrosive chemicals: PTFE's universal chemical inertness is non-negotiable for storing strong acids, bases, and aggressive organic solvents that would destroy other materials.

- If your primary focus is extreme temperature applications: PTFE is essential for experiments involving cryogenic storage or high-temperature digestions where other materials would become brittle, melt, or shatter.

- If your primary focus is sample purity and complete recovery: PTFE's non-leaching, non-stick properties ensure your sample remains uncontaminated and that you can retrieve every last bit for accurate analysis.

Ultimately, choosing PTFE laboratory bottles is an investment in data integrity and safety for your most demanding scientific work.

Summary Table:

| Advantage | Key Feature | Benefit |

|---|---|---|

| Chemical Resistance | Inert to strong acids, alkalis, solvents | Prevents contamination and degradation |

| Temperature Tolerance | Performs from -270°C to 260°C | Suitable for cryogenic and high-temp use |

| Physical Properties | Non-stick surface, durable construction | Ensures sample recovery and long lifespan |

| Purity Standards | FDA/USP Class VI certified | Ideal for pharmaceutical and biological work |

Ready to enhance your lab's integrity with premium PTFE solutions?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and labware—for semiconductor, medical, laboratory, and industrial applications. Our expertise ensures your most critical samples are protected from contamination, thermal stress, and chemical attack.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision and reliability. Let us provide the certainty your work demands.

Contact KINTEK today to discuss your specific PTFE laboratory bottle needs and receive a personalized quote.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

People Also Ask

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss

- Why are PTFE vials considered environmentally friendly? Reduce Lab Waste with Durable Reusables

- What are the common characteristics of Teflon? Unlocking Extreme Chemical and Thermal Resistance

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- What are the primary applications of Teflon? Leverage Its Unique Properties for Your Industry