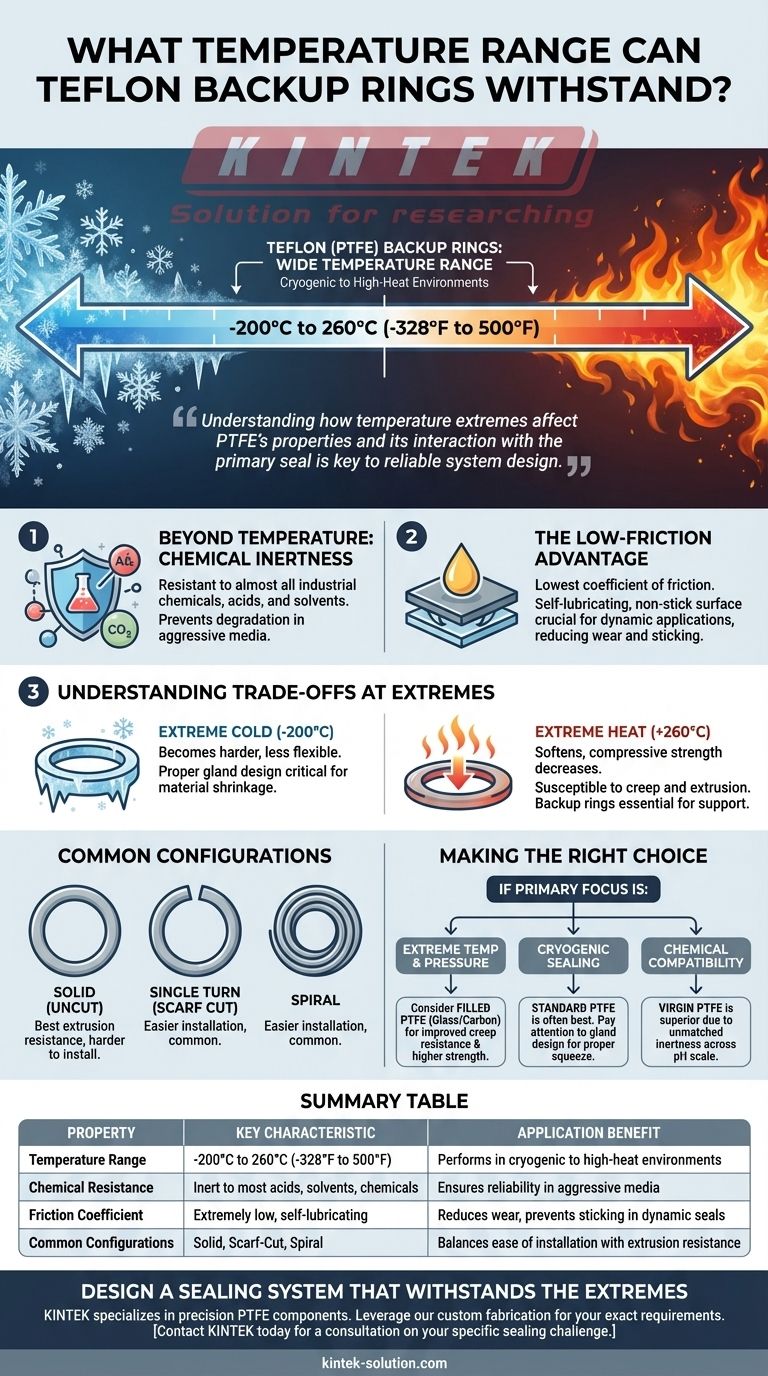

In most industrial applications, Teflon (PTFE) backup rings can withstand an exceptionally wide temperature range, typically from -200°C to 260°C (-328°F to 500°F). This makes them a default choice for sealing systems operating in extreme thermal conditions, from cryogenic processes to high-heat environments.

While the raw material has a broad temperature tolerance, the true challenge is understanding how temperature extremes affect its mechanical properties and its interaction with the primary seal, which is the key to designing a reliable system.

The Properties Behind PTFE's Performance

Polytetrafluoroethylene (PTFE), the material behind the Teflon™ brand, is not chosen for temperature resistance alone. Its value comes from a unique combination of properties that makes it highly effective as a backup ring material in demanding scenarios.

Unpacking the Temperature Range

The widely cited range of -200°C to 260°C reflects the thermal stability of pure, virgin PTFE. Within this window, the material does not melt or become chemically unstable.

This broad tolerance makes it suitable for applications that other elastomers or plastics simply cannot handle.

Beyond Temperature: Chemical Inertness

A critical feature of PTFE is its near-total chemical inertness. It is resistant to almost all industrial chemicals, acids, and solvents.

This ensures that the backup ring will not degrade when exposed to aggressive media, which is a common point of failure for other materials.

The Low-Friction Advantage

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating, non-stick surface is crucial in dynamic applications.

It reduces wear and tear on moving parts and prevents the backup ring from sticking to the O-ring or hardware, ensuring smooth operation.

Understanding the Trade-offs at Temperature Extremes

A material's temperature rating is not the full story. The mechanical behavior of PTFE changes significantly at the ends of its operating range, and these changes must be accounted for in system design.

The Impact of Extreme Cold

As PTFE approaches its lower limit of -200°C, it becomes harder and less flexible.

While it does not become brittle in the same way as many plastics, its ability to conform to surfaces is reduced. Proper gland design is critical to accommodate material shrinkage and maintain an effective seal.

The Impact of Extreme Heat

At the upper end of its range, approaching +260°C, PTFE softens and its compressive strength decreases.

This increases its susceptibility to creep (slow deformation under load) and extrusion. This is precisely why backup rings are essential in high-pressure, high-temperature applications—to support the primary O-ring which is also softening.

The Purpose of Different Configurations

The physical shape of the backup ring is designed to optimize installation and performance. The most common types are solid (uncut), single turn (scarf cut), and spiral.

Solid rings offer the best extrusion resistance but can be difficult to install. Scarf-cut and spiral rings are much easier to install over shafts and into internal grooves, making them far more common in practice.

Making the Right Choice for Your Application

Selecting the correct backup ring involves matching the material properties and configuration to the specific demands of your system.

- If your primary focus is extreme temperature and high pressure: Virgin PTFE is an excellent starting point, but consider filled PTFE grades (e.g., glass or carbon-filled) for improved creep resistance and higher strength at elevated temperatures.

- If your primary focus is cryogenic sealing: Standard PTFE is often the best choice, but pay close attention to the seal gland design to ensure it maintains the proper squeeze on the O-ring as materials contract.

- If your primary focus is chemical compatibility: Virgin PTFE is almost always the superior choice due to its unmatched chemical inertness across the entire pH scale.

Ultimately, understanding how temperature affects PTFE's physical properties is the key to designing a robust and reliable sealing system.

Summary Table:

| Property | Key Characteristic | Application Benefit |

|---|---|---|

| Temperature Range | -200°C to 260°C (-328°F to 500°F) | Performs in cryogenic to high-heat environments |

| Chemical Resistance | Inert to most acids, solvents, and chemicals | Ensures reliability in aggressive media |

| Friction Coefficient | Extremely low, self-lubricating | Reduces wear and prevents sticking in dynamic seals |

| Common Configurations | Solid, Scarf-Cut, Spiral | Balances ease of installation with extrusion resistance |

Design a Sealing System That Withstands the Extremes

Navigating the trade-offs between temperature, pressure, and chemical exposure is complex. KINTEK specializes in manufacturing precision PTFE components, including backup rings, seals, and custom labware. We help engineers in the semiconductor, medical, and industrial sectors achieve reliable performance in the most demanding applications.

Leverage our expertise in custom fabrication—from prototypes to high-volume orders—to get components tailored to your exact thermal and mechanical requirements.

Contact KINTEK today for a consultation on your specific sealing challenge.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions