In short, medical applications that require exceptional navigational control and durability in complex anatomical environments benefit most from PTFE liners with high yield strength. These include advanced catheter systems for cardiovascular and neurovascular interventions, guidewires, and introducer sheaths used in minimally invasive surgery. The material’s strength allows for thinner, more robust device construction, which is critical for performance and patient safety.

The central challenge in advanced catheter design is balancing a small profile with high performance. High yield strength PTFE directly addresses this by enabling the creation of extremely thin, durable liners that resist stretching and kinking, ultimately leading to more precise and reliable medical devices.

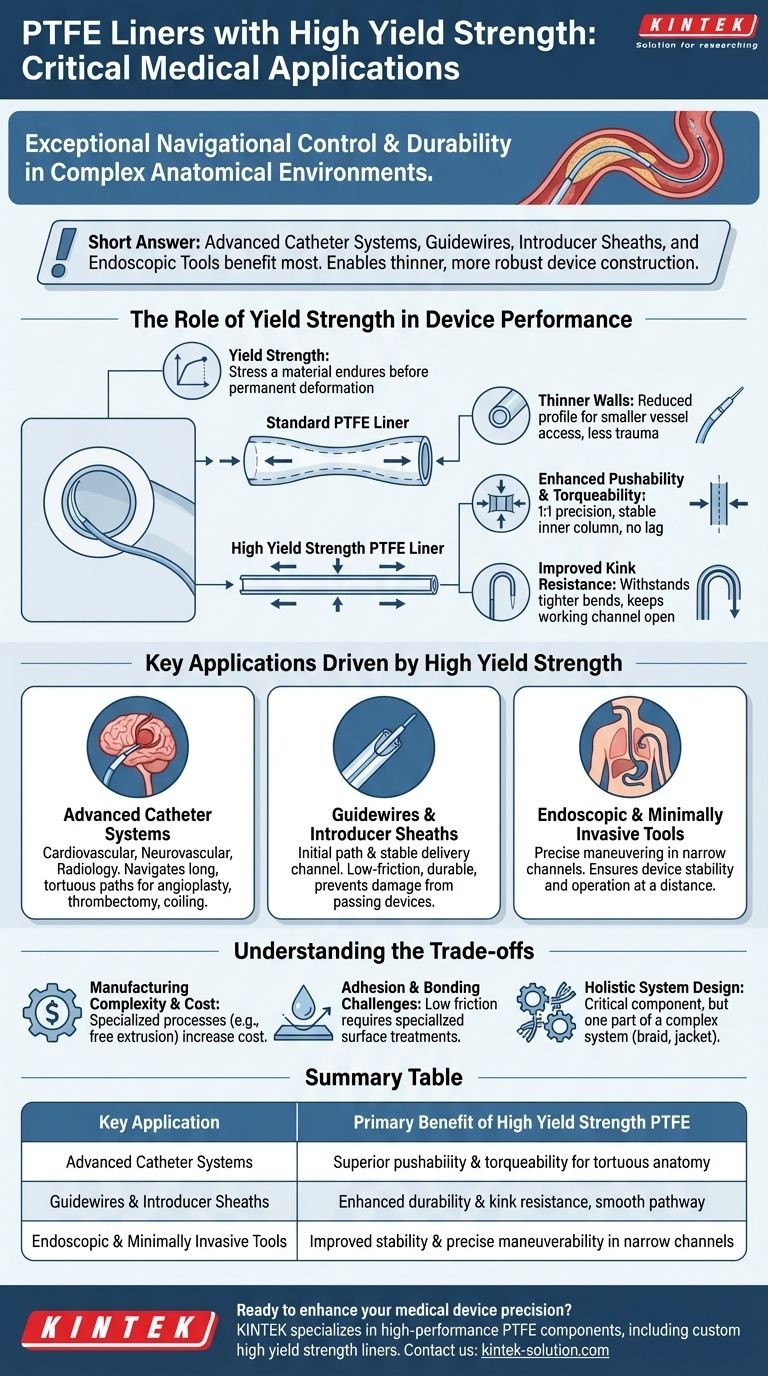

The Role of Yield Strength in Device Performance

To understand the application, you must first understand the engineering principle. Yield strength is the amount of stress a material can endure before it begins to deform permanently. For a PTFE liner, this property is not about simple toughness; it is about maintaining its precise form and function under duress.

What is High Yield Strength PTFE?

High yield strength PTFE is a specialized grade of the material, often produced through a specific process like free extrusion. This manufacturing method enhances the material's molecular structure, significantly increasing its resistance to permanent stretching or compression compared to standard PTFE.

This means that when a catheter is pushed, pulled, or bent, the high yield strength liner is far less likely to lengthen, compress, or collapse.

Enabling Thinner, Stronger Walls

The primary advantage of high yield strength is the ability to engineer liners with thinner walls without compromising structural integrity. A thinner liner directly contributes to a smaller overall catheter profile.

This reduction is critical for accessing smaller vessels, reducing patient trauma, and enabling more complex procedures in delicate areas like the brain or coronary arteries.

Enhancing Pushability and Torqueability

Pushability (the transmission of force from the hub to the tip) and torqueability (the response of the tip to rotation at the hub) are paramount for catheter control.

A low-strength liner can act like a spring, compressing or stretching as force is applied, creating a lag in response. A high yield strength liner provides a rigid, stable inner column, ensuring that the physician's movements are translated to the device's tip with 1:1 precision.

Improving Kink Resistance

When a catheter navigates a sharp turn in a blood vessel, it is susceptible to kinking, which can obstruct the inner lumen and lead to device failure.

A liner with high yield strength offers superior kink resistance. It can withstand a tighter bend radius before collapsing, ensuring the working channel of the device remains open and functional throughout the procedure.

Key Applications Driven by High Yield Strength

The unique mechanical advantages of high yield strength PTFE make it the material of choice for the most demanding medical devices.

Advanced Catheter Systems

In fields like interventional cardiology, radiology, and neurovascular surgery, catheters must navigate long, tortuous paths. Devices for angioplasty, thrombectomy, and aneurysm coiling rely on high yield strength liners to reach their target destination reliably and safely.

Guidewires and Introducer Sheaths

Guidewires create the initial path, and introducer sheaths provide a stable channel for delivering larger devices. The PTFE liner in these tools must be both incredibly low-friction and durable.

High yield strength prevents the liner from being scraped or damaged as other devices are passed through it, ensuring a smooth and reliable pathway.

Endoscopic and Minimally Invasive Tools

Any flexible tool that must be precisely maneuvered through a narrow channel benefits from this material. This includes certain endoscopic instruments and delivery systems for stents or heart valves. The liner's stability ensures the device operates as intended, even at a distance.

Understanding the Trade-offs

While highly advantageous, specifying high yield strength PTFE is an engineering decision with specific considerations.

Manufacturing Complexity and Cost

Achieving high yield strength often requires more controlled and specialized extrusion processes. This can increase the material cost and may limit the number of qualified suppliers compared to standard-grade PTFE.

Adhesion and Bonding Challenges

PTFE is famously non-stick due to its low coefficient of friction. While excellent for device performance, this property makes it difficult to bond the liner to other layers of the catheter, such as braided wire reinforcement or the outer polymer jacket. This requires specialized surface treatments or proprietary manufacturing techniques.

It's a System, Not a Standalone Solution

The PTFE liner is one component in a complex system. While its properties are critical, the overall catheter performance also depends on the braid pattern, wire selection, and the durometer of the outer jacket materials. High yield strength enhances the system but does not replace the need for holistic design.

Making the Right Choice for Your Device

Your material choice should be driven by the clinical demands of the procedure for which the device is intended.

- If your primary focus is navigating tortuous anatomy with maximum precision: A high yield strength PTFE liner is the definitive choice for improving pushability and kink resistance.

- If your primary focus is a simple, large-diameter delivery system for straight pathways: Standard-grade PTFE may provide sufficient performance at a lower cost.

- If your primary focus is ensuring biocompatibility and chemical inertness: Both standard and high yield strength PTFE are physiologically inert and meet stringent regulatory requirements.

Ultimately, selecting a high yield strength PTFE liner is a direct investment in the control, reliability, and safety of your medical device.

Summary Table:

| Key Application | Primary Benefit of High Yield Strength PTFE |

|---|---|

| Advanced Catheter Systems | Superior pushability and torqueability for navigating tortuous anatomy |

| Guidewires & Introducer Sheaths | Enhanced durability and kink resistance, maintaining a smooth pathway |

| Endoscopic & Minimally Invasive Tools | Improved stability and precise maneuverability in narrow channels |

Ready to enhance the precision and reliability of your medical device?

KINTEK specializes in manufacturing high-performance PTFE components, including custom liners with high yield strength, for the medical, semiconductor, and laboratory industries. Our precision production and custom fabrication—from prototypes to high-volume orders—ensure your device meets the highest standards for performance and patient safety.

Contact us today to discuss how our PTFE solutions can benefit your next project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What industries commonly use PTFE expansion joints and why? Solve Critical Pipeline Challenges with PTFE

- What industries commonly use Teflon-encapsulated O-Rings? Critical Seals for Extreme Conditions

- What is the maximum pressure that PTFE piston seals can handle? Understand the Full System of Limits

- What are the key properties of PTFE industrial coating? Discover Unmatched Performance for Demanding Industries

- What are the uses of PTFE coatings in the semiconductor and electronics industries? Ensure Purity & Reliability

- What are the typical applications of PTFE lined ball valves? Essential for Corrosive & High-Purity Systems

- What are the primary applications of extra-thick PTFE washers (5mm – 6mm)? Critical for High-Pressure Sealing & Load-Bearing

- How do Teflon washers compare to phosphor bronze washers in terms of wear? Choose the Right Washer for Your Application