Primarily, PTFE lined ball valves are indispensable in any industry that handles highly corrosive or high-purity fluids. They are the go-to solution for on/off control in applications found throughout chemical processing, pharmaceutical manufacturing, food and beverage production, and power generation plants. Their core function is to provide reliable shutoff while preventing chemical attack on the valve's structural components.

The fundamental application of a PTFE lined ball valve is not just to control flow, but to do so while creating a chemically inert barrier. This design protects the valve from corrosive media and, just as importantly, protects the media from metallic contamination.

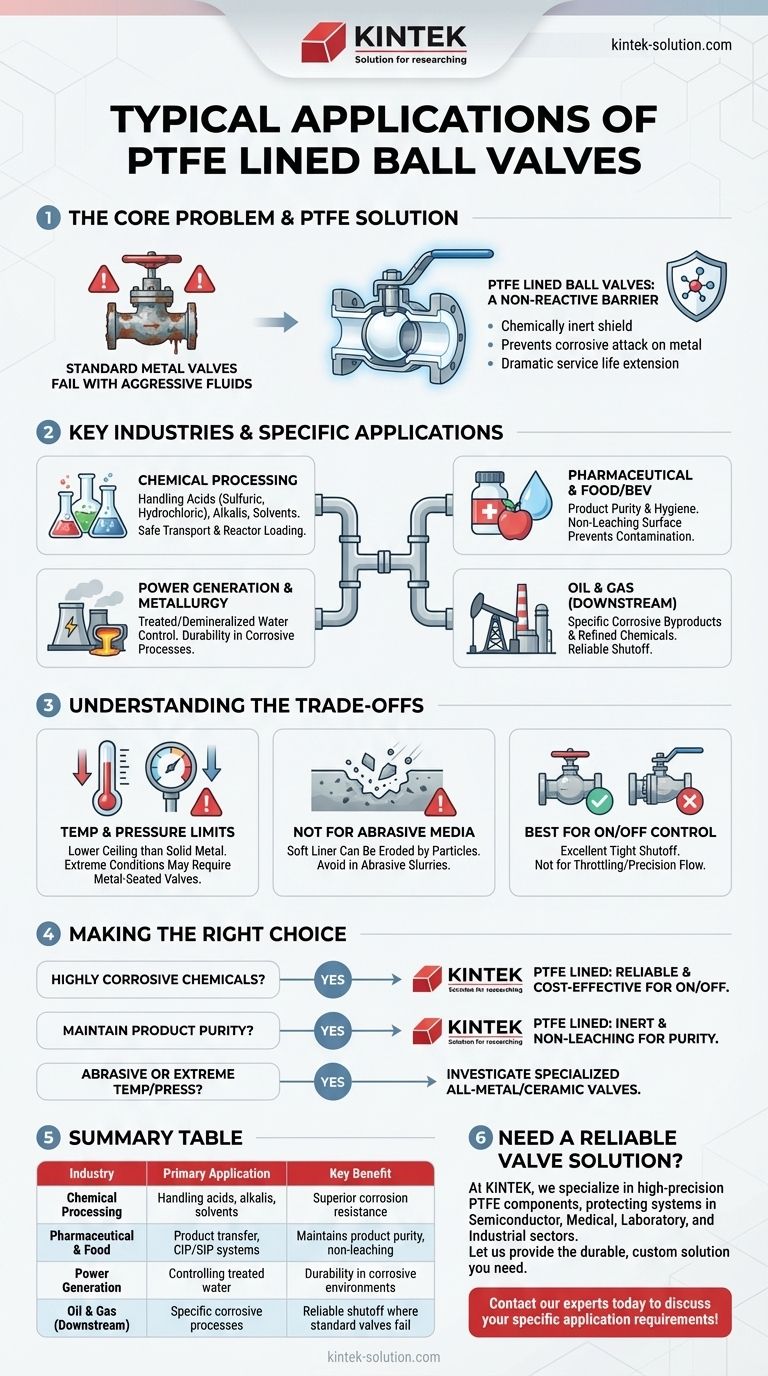

The Core Problem: Handling Aggressive Fluids

Standard valves present a significant point of failure when integrated into systems that transport corrosive or sensitive media. Understanding this challenge clarifies why a lined valve is often a necessity, not a luxury.

The Failure of Standard Metal Valves

When exposed to aggressive media like acids, alkalis, or solvents, unlined metal valves begin to corrode almost immediately. This degradation leads to valve failure, dangerous leaks, and contamination of the process fluid.

The PTFE Solution: A Non-Reactive Barrier

A PTFE lined ball valve encases all wetted parts—the valve body and the ball—in a seamless layer of Polytetrafluoroethylene (PTFE). This lining acts as a complete and impenetrable shield.

Because PTFE is chemically inert to a vast range of substances, the corrosive fluid never makes contact with the valve's metal structure. This extends the valve's service life dramatically.

Ensuring Purity in Sensitive Processes

In industries like pharmaceuticals or food and beverage, preventing contamination is paramount. The non-reactive, non-leaching surface of the PTFE liner ensures that the purity of the product passing through the valve is maintained.

Key Industries and Specific Applications

The unique properties of PTFE make these valves critical components in several demanding sectors.

Chemical Processing

This is the most common application. PTFE lined ball valves are used to handle bulk and specialty chemicals, including highly corrosive acids (sulfuric, hydrochloric), alkalis, salts, and organic solvents. They are essential for safe and reliable pipeline transport and reactor loading/unloading.

Pharmaceutical and Food & Beverage

In these industries, the dual benefit of corrosion resistance and purity is critical. The valves handle everything from cleaning agents to final product streams, ensuring no metallic ions can leach into the media and compromise safety or quality.

Power Generation and Metallurgy

Power plants and metallurgical facilities often use chemically treated water, demineralized water, or other corrosive fluids in their processes. PTFE lined valves provide a durable solution for controlling these media without rapid degradation.

Oil and Gas

While not for all applications, these valves are used in specific downstream processes where corrosive byproducts or refined chemicals are present, requiring the chemical resistance that standard metal valves lack.

Understanding the Trade-offs

While highly effective, PTFE lined ball valves are not a universal solution. Their design imposes specific limitations that must be respected for successful implementation.

Temperature and Pressure Limitations

PTFE has a lower operating temperature and pressure ceiling than solid metal. In applications involving extreme heat or high pressures, a specialized metal-seated ball valve may be required.

Not Ideal for Abrasive Media

The PTFE liner, while durable against chemicals, is relatively soft. It is not suitable for applications involving abrasive slurries, as the suspended particles can quickly erode the liner and cause the valve to fail.

Best Suited for On/Off Control

Like most ball valves, the PTFE lined design excels at providing tight, reliable shutoff (on/off service). It is not designed for throttling or precision flow control, as this can cause uneven wear on the seats and liner.

Making the Right Choice for Your System

Selecting the correct valve is a matter of matching the technology to the operational demands of your specific application.

- If your primary focus is handling highly corrosive chemicals: A PTFE lined ball valve is often the most reliable and cost-effective solution for on/off control.

- If your primary focus is maintaining product purity (pharma, food): The non-leaching, inert nature of the PTFE liner is essential to prevent contamination.

- If your system involves abrasive slurries or extreme temperatures/pressures: You must investigate specialized all-metal or ceramic valves, as a PTFE liner will not be durable enough.

Ultimately, selecting a PTFE lined ball valve is a strategic choice for ensuring system integrity and longevity when faced with chemically aggressive media.

Summary Table:

| Industry | Primary Application | Key Benefit |

|---|---|---|

| Chemical Processing | Handling acids, alkalis, solvents | Superior corrosion resistance |

| Pharmaceutical & Food | Product transfer, CIP/SIP systems | Maintains product purity, non-leaching |

| Power Generation | Controlling treated/demineralized water | Durability in corrosive environments |

| Oil & Gas (Downstream) | Specific corrosive chemical processes | Reliable shutoff where standard valves fail |

Need a reliable valve solution for your aggressive media?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom-fabricated seals, liners, and labware. Our expertise ensures your systems in the semiconductor, medical, laboratory, and industrial sectors are protected from corrosion and contamination.

Let us provide the durable, custom solution you need—from prototypes to high-volume orders.

Contact our experts today to discuss your specific application requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts