In short, Teflon-encapsulated O-rings are critical components in industries where extreme chemical resistance and temperature tolerance are non-negotiable. They are most commonly used in chemical processing, oil and gas, food and beverage, pharmaceutical, and aerospace sectors for sealing applications in equipment like pumps, valves, and reactors.

The fundamental value of a Teflon-encapsulated O-ring is its ability to combine the superior chemical inertness and temperature range of a Teflon jacket with the reliable, compressive sealing force of an elastomer core. It solves the problem of needing a chemically-resistant seal that still behaves like a flexible O-ring.

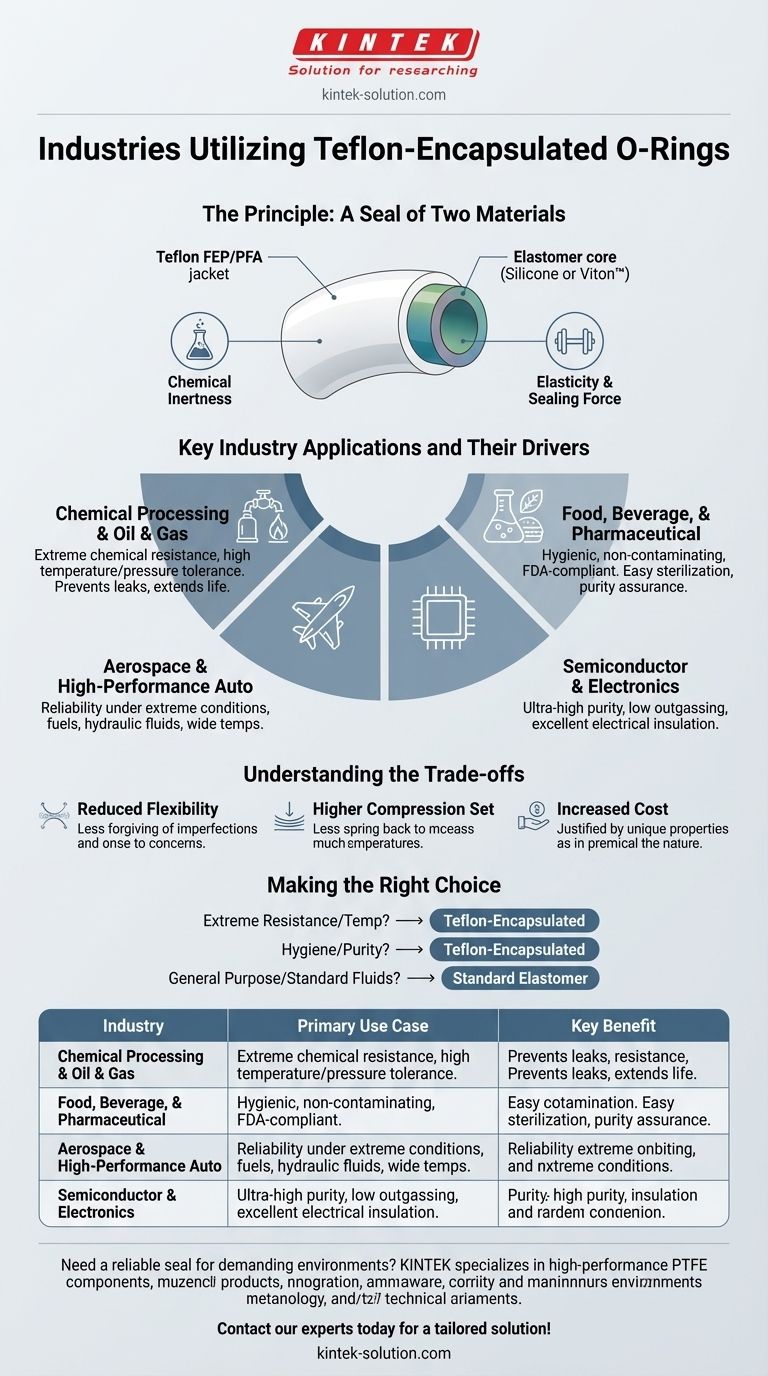

The Principle: A Seal of Two Materials

Teflon-encapsulated O-rings are composite seals. They are not made of solid Teflon (PTFE), but rather feature a core of elastomeric material, like Silicone or Viton™, wrapped in a thin, seamless jacket of Teflon FEP or PFA.

Combining Chemical Inertness with Elasticity

The outer Teflon jacket provides exceptional resistance to virtually all industrial chemicals, solvents, and corrosive agents.

The inner elastomer core provides the flexibility and memory needed for the O-ring to compress and maintain a tight, reliable seal, something a solid Teflon ring cannot do effectively.

High-Purity and Low-Friction Performance

The Teflon surface is non-contaminating and has an extremely low coefficient of friction. This makes it ideal for applications in the food, beverage, and pharmaceutical industries where purity is paramount and for dynamic seals where friction can cause wear.

Key Industry Applications and Their Drivers

The unique properties of these seals make them indispensable in several demanding fields. Each industry leverages a specific combination of their benefits.

Chemical Processing and Oil & Gas

In these sectors, equipment like pumps, valves, reactors, and pipelines handle highly aggressive chemicals, often at high temperatures and pressures.

Standard elastomer O-rings would quickly degrade. The Teflon encapsulation provides the necessary chemical barrier to prevent leaks, ensure safety, and extend the service life of critical components.

Food, Beverage, and Pharmaceutical

Hygiene and non-contamination are the primary drivers here. The Teflon surface is chemically inert, FDA-compliant, and easy to sterilize.

These O-rings ensure that no material from the seal leaches into the product, maintaining the integrity and safety required in food processing and pharmaceutical manufacturing equipment.

Aerospace and High-Performance Automotive

Applications in hydraulic systems, fuel lines, and propulsion systems demand absolute reliability under extreme conditions.

Teflon-encapsulated O-rings provide a robust seal against aggressive fuels, hydraulic fluids, and wide temperature fluctuations, ensuring operational integrity where failure is not an option.

Semiconductor and Electronics

In semiconductor manufacturing, even microscopic contamination can ruin an entire batch of microchips. The purity and low-outgassing properties of the Teflon jacket are essential.

Additionally, its excellent electrical insulation properties make it valuable for sealing components in sensitive electronic equipment.

Understanding the Trade-offs

While highly effective, these seals are not a universal solution. Understanding their limitations is key to using them correctly.

Reduced Flexibility

The Teflon jacket is more rigid than a standard elastomer. This means encapsulated O-rings are less forgiving of surface imperfections in the sealing groove and require more care during installation to avoid scratches or damage.

Higher Compression Set

Because the Teflon jacket is not truly elastic, these seals can be more susceptible to taking a "set" after being compressed for a long time. They do not spring back with the same force as a high-performance elastomer, which can be a factor in applications with frequent pressure cycles.

Increased Cost

The multi-material construction and manufacturing process make Teflon-encapsulated O-rings more expensive than standard nitrile or Viton™ O-rings. Their use is justified only when their unique properties are required.

Making the Right Choice for Your Goal

Selecting the correct seal depends entirely on the demands of your specific application.

- If your primary focus is extreme chemical resistance or temperature range: A Teflon-encapsulated O-ring is almost certainly the correct technical choice, justifying its higher cost.

- If your primary focus is hygiene and non-contamination: This is a leading solution for food, beverage, and pharmaceutical applications due to its inert, FDA-compliant surface.

- If your primary focus is general-purpose sealing with standard oils and fluids: A standard, lower-cost elastomer O-ring made from Nitrile or Viton™ is likely a more practical and economical solution.

Ultimately, choosing a Teflon-encapsulated O-ring is a strategic decision for environments where conventional seals would fail.

Summary Table:

| Industry | Primary Use Case | Key Benefit |

|---|---|---|

| Chemical Processing | Seals in pumps, valves, reactors | Extreme chemical resistance |

| Oil & Gas | Pipeline and equipment seals | High temperature and pressure tolerance |

| Pharmaceutical | Sterile processing equipment | Non-contaminating, FDA-compliant surface |

| Food & Beverage | Sanitary fluid handling | Easy sterilization, purity assurance |

| Aerospace | Hydraulic and fuel systems | Reliability under extreme conditions |

Need a reliable seal for demanding environments? KINTEK specializes in high-performance PTFE components, including custom Teflon-encapsulated O-rings for semiconductor, medical, laboratory, and industrial applications. We combine precision manufacturing with custom fabrication—from prototypes to high-volume orders—to deliver seals that meet your exact specifications for chemical resistance, temperature tolerance, and purity. Contact our experts today to discuss your sealing challenges and get a solution tailored to your needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech