At its core, PTFE expansion joints are specified in industries where chemical resistance, temperature tolerance, and product purity are non-negotiable. The primary users are chemical processing, pharmaceutical, food and beverage, and power generation plants, each leveraging the material's unique properties to solve critical operational challenges in their pipeline systems.

The widespread use of PTFE expansion joints is not a matter of preference but a strategic engineering choice. Its unique combination of near-universal chemical inertness, high-temperature stability, and non-contaminating surface makes it the ideal solution for protecting critical pipeline systems in demanding industries.

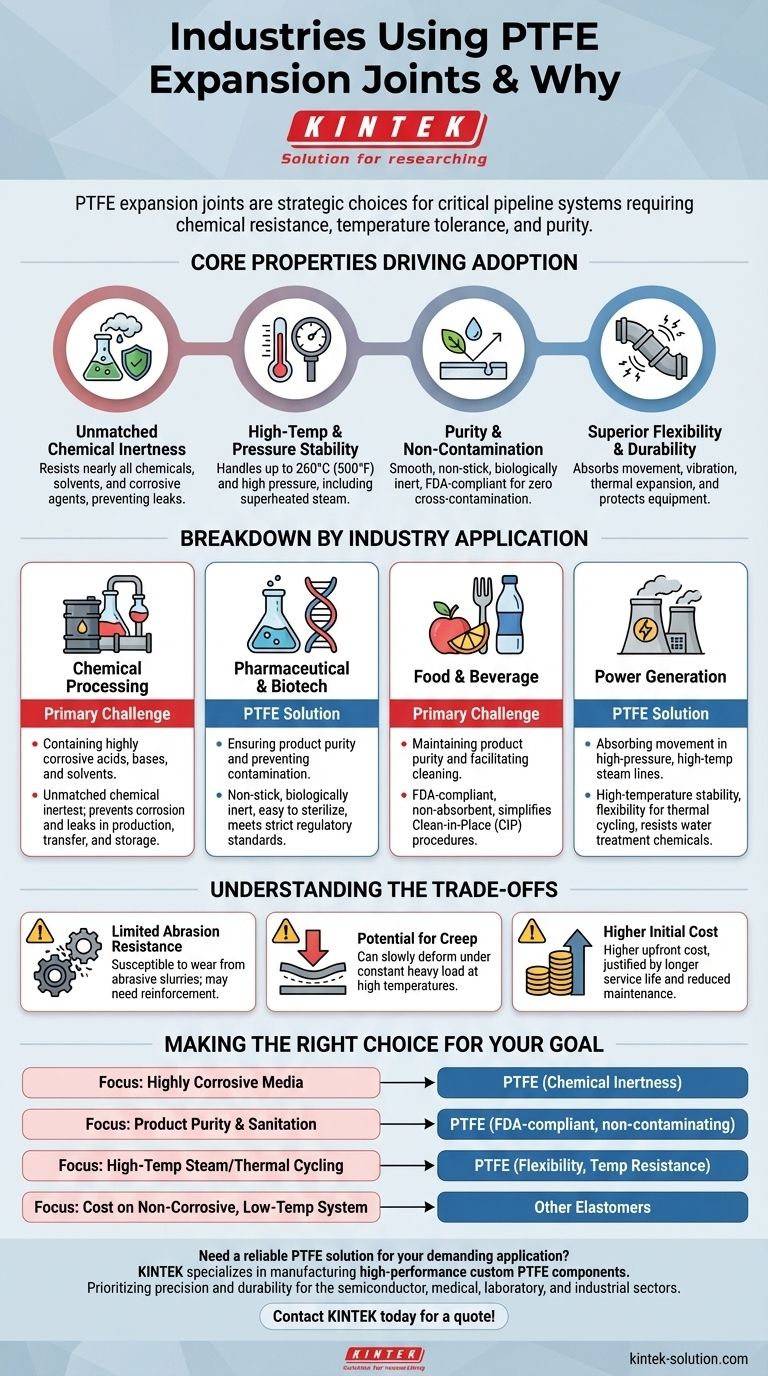

The Core Properties Driving Adoption

To understand why these specific industries rely on Polytetrafluoroethylene (PTFE), we must first look at its fundamental material characteristics. The choice of an expansion joint is dictated by the environment it must survive.

Unmatched Chemical Inertness

PTFE is famous for being resistant to nearly all industrial chemicals, solvents, and corrosive agents. This property is its most significant advantage.

Where other materials would degrade and fail, PTFE provides a reliable barrier, preventing dangerous leaks and costly system downtime.

High-Temperature and Pressure Stability

PTFE can operate continuously at high temperatures (up to 260°C or 500°F) and handle high-pressure applications, particularly superheated steam.

This allows it to function in high-energy systems like power plants and chemical reactors where many elastomers would quickly perish.

Purity and Non-Contamination

The surface of PTFE is exceptionally smooth and non-stick, which prevents materials from adhering to it. It is also biologically inert and can meet strict FDA standards.

This is critical in applications where purity is paramount, as it prevents cross-contamination and ensures the final product remains unadulterated.

Superior Flexibility and Durability

As an expansion joint, the material must absorb movement. PTFE effectively handles vibration, thermal expansion and contraction, and pipe misalignment, protecting pumps, vessels, and other critical equipment from stress-induced damage.

A Breakdown by Industry Application

Each industry leverages these core properties to address its specific operational needs.

Chemical Processing

In this sector, the primary challenge is safely containing and transporting highly corrosive acids, bases, and solvents.

PTFE expansion joints are the default choice for these applications because they will not corrode, ensuring the integrity of the pipeline and the safety of personnel. They are used in systems for chemical production, transfer, and storage.

Pharmaceutical and Biotech

Hygiene and the prevention of contamination are the highest priorities. Systems must be sterilized and cleaned without degrading equipment or leaving residue.

The non-stick, non-contaminating surface of PTFE makes it easy to clean and sterilize. Its inertness guarantees that it will not react with or leach into sensitive biological or chemical compounds, meeting stringent regulatory standards.

Food and Beverage

Similar to pharmaceuticals, this industry requires absolute purity. Equipment must not alter the taste, smell, or composition of the product.

PTFE's FDA-compliant and non-absorbent nature makes it a perfect fit. Its non-stick properties also facilitate the flow of viscous materials and simplify clean-in-place (CIP) procedures.

Power Generation

Power plants operate with high-pressure steam lines that experience significant temperature fluctuations, leading to thermal expansion and contraction of pipes.

PTFE expansion joints are used here to absorb this movement and withstand the high temperatures and pressures of steam. They also resist the corrosive effects of water treatment chemicals used in the system.

Understanding the Trade-offs

While incredibly versatile, PTFE is not without its limitations. An objective assessment requires acknowledging its trade-offs.

Limited Abrasion Resistance

Compared to hard metals, PTFE is a relatively soft material. In pipelines carrying abrasive slurries, it can be susceptible to wear over time unless specifically designed with reinforcement.

Potential for Creep

Under a constant, heavy load (a phenomenon known as "creep"), especially at elevated temperatures, PTFE can slowly deform. This must be considered during the design and installation of the joint.

Higher Initial Cost

PTFE expansion joints typically have a higher upfront cost than many standard rubber or elastomer alternatives. However, this cost is often justified by a longer service life and reduced maintenance in aggressive chemical or high-temperature environments.

Making the Right Choice for Your Goal

Selecting an expansion joint requires matching the material to the system's demands.

- If your primary focus is handling highly corrosive media: PTFE is often the only viable choice due to its near-universal chemical inertness.

- If your primary focus is product purity and sanitation: PTFE's non-contaminating, FDA-compliant properties make it the standard for pharmaceutical and food-grade applications.

- If your primary focus is managing high-temperature steam or thermal cycling: PTFE provides the necessary flexibility and temperature resistance that many elastomers cannot.

- If your primary focus is cost on a non-corrosive, low-temperature system: A different material, like a specific elastomer, might be a more economical and perfectly suitable solution.

Ultimately, specifying PTFE expansion joints is a strategic decision to ensure system integrity, safety, and longevity in the most demanding operational environments.

Summary Table:

| Industry | Primary Challenge | PTFE Solution |

|---|---|---|

| Chemical Processing | Containing corrosive acids, bases, and solvents | Unmatched chemical inertness prevents corrosion and leaks |

| Pharmaceutical/Biotech | Ensuring product purity and preventing contamination | Non-stick, biologically inert surface; easy to sterilize |

| Food & Beverage | Maintaining product purity and facilitating cleaning | FDA-compliant, non-absorbent, non-contaminating |

| Power Generation | Absorbing movement in high-pressure, high-temperature steam lines | High-temperature stability and flexibility for thermal cycling |

Need a reliable PTFE solution for your demanding application?

KINTEK specializes in manufacturing high-performance PTFE components, including custom expansion joints, seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors, prioritizing precision and durability.

Whether you need a prototype or a high-volume order, our custom fabrication expertise ensures your system operates with integrity, safety, and longevity.

Contact KINTEK today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- How do Teflon sheets protect garments during heat transfers? Essential Guide for Flawless Results

- What is the recommended method for bonding PTFE to its support? Achieve a Permanent, High-Strength Bond

- What are the advantages of CNC machining for PTFE components? Achieve Unmatched Precision for Complex Parts

- What are the tensile strengths of PTFE and graphite packing? Choosing the Right Material for Your Application

- What factors should be considered when choosing between PTFE and NBR oil seals? Select the Right Seal for Your Application

- What are the general functions of bellows in mechanical systems? Achieve Superior System Reliability

- What are the different types of PTFE diaphragms and their applications? Optimize Your Chemical Processing System

- How are PTFE rotary shaft lip seals utilized in the automotive industry? Essential for High-Performance & EV Systems