In semiconductor and electronics manufacturing, Polytetrafluoroethylene (PTFE) coatings are primarily used for their exceptional chemical inertness and superior electrical insulation. In semiconductor fabrication, this non-reactive and non-stick nature is critical for protecting sensitive components from contamination during chemical processes. For electronics, its high dielectric strength makes it an indispensable insulator for circuit boards, connectors, and high-frequency cables.

The value of PTFE in these high-purity environments isn't just one feature, but its unique combination of properties. It simultaneously provides extreme chemical resistance, excellent electrical insulation, and non-stick surfaces, making it indispensable for maintaining both material purity and signal integrity.

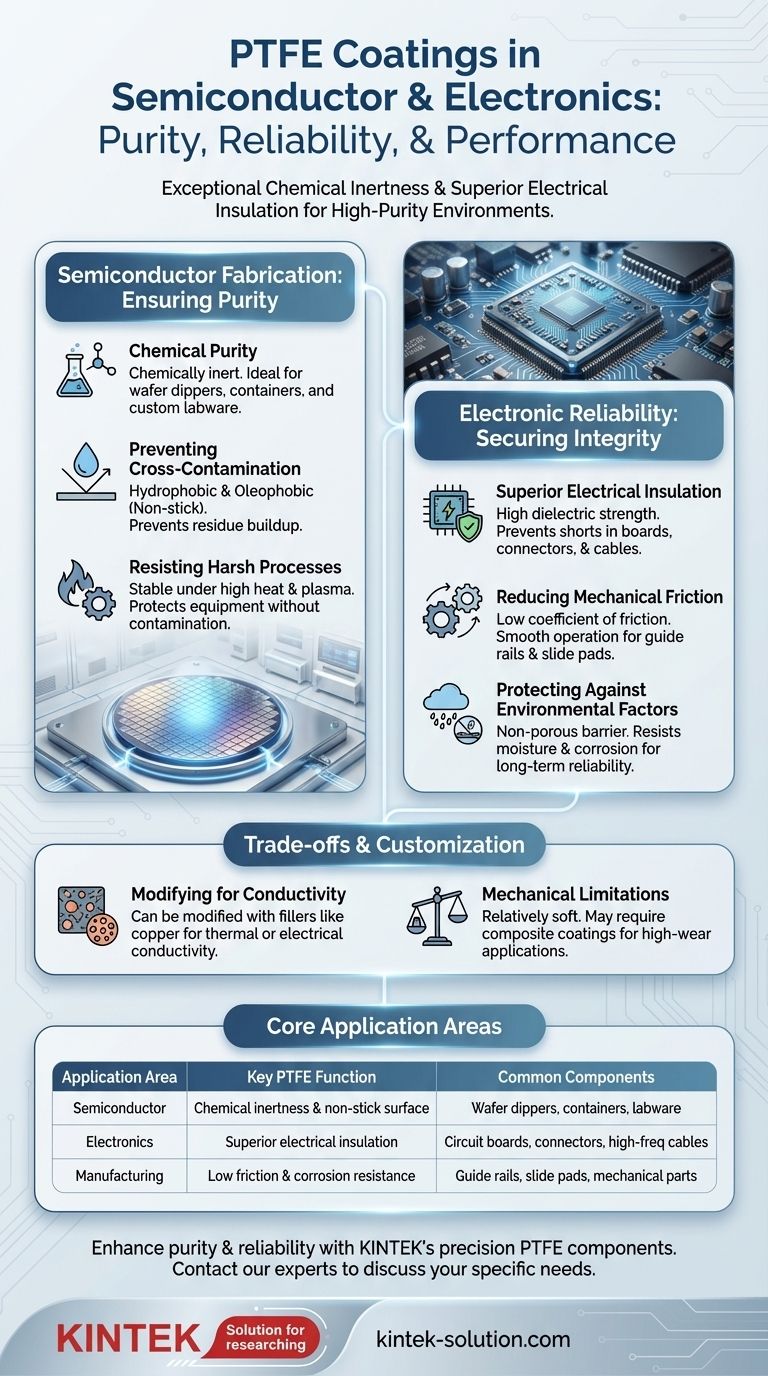

The Critical Role in Semiconductor Fabrication

The production of semiconductors is an exceptionally sensitive process where even microscopic contamination can lead to component failure. PTFE's properties directly address these challenges.

Ensuring Chemical Purity

PTFE is almost completely chemically inert, meaning it does not react with the vast majority of corrosive chemicals used in semiconductor manufacturing.

This non-reactive quality makes it the ideal material for wafer dippers, containers, and custom labware, ensuring that the coating itself does not leach impurities into the process.

Preventing Cross-Contamination

PTFE is both hydrophobic (repels water) and oleophobic (repels oil), giving it powerful non-wetting or non-stick characteristics.

This property ensures that chemical residues can be removed easily and completely, preventing leftover materials from one step from contaminating the next and ensuring final product purity.

Resisting Harsh Processes

Semiconductor fabrication often involves extreme conditions, including exposure to high temperatures and plasma.

PTFE remains chemically stable under these harsh conditions, protecting the underlying equipment and components without degrading or introducing foreign particles into the manufacturing environment.

The Foundation of Electronic Reliability

In electronics, the primary goals are ensuring signal integrity and long-term durability. PTFE coatings provide a robust solution for protecting sensitive circuits and components.

Providing Superior Electrical Insulation

PTFE has an exceptionally high dielectric strength, making it one of the best solid insulating materials known.

It is widely used for insulating circuit boards, connectors, and high-performance cables, preventing electrical shorts and minimizing signal loss, especially in high-frequency applications.

Reducing Mechanical Friction

Within the automated machinery used to manufacture electronics, reducing wear and energy consumption is crucial.

PTFE's low coefficient of friction makes it an ideal coating for guide rails and low-friction slide pads, ensuring smooth, reliable operation of manufacturing equipment.

Protecting Against Environmental Factors

Finished electronic devices must be able to withstand exposure to moisture and other environmental conditions.

The non-porous and corrosion-resistant nature of PTFE coatings provides a protective barrier for circuits and connectors, enhancing their long-term reliability.

Understanding the Trade-offs and Considerations

While highly effective, PTFE is not a universal solution. Understanding its limitations is key to using it correctly.

Modifying for Conductivity

By itself, PTFE is a superior insulator. However, its properties can be intentionally modified for specific needs.

In some applications, fillers like copper can be added to the PTFE matrix to enhance thermal or electrical conductivity, turning it from an insulator into a controlled conductor for heat dissipation or specialized electrical uses.

Mechanical Limitations

While PTFE has an extremely low-friction surface, it is a relatively soft material.

In high-wear mechanical applications, pure PTFE may not be durable enough. This often necessitates the use of composite coatings or fillers to improve its abrasion resistance.

Applying PTFE to Your Project

Choosing to use PTFE depends entirely on your primary engineering goal.

- If your primary focus is process purity: Leverage PTFE's non-reactive and non-wetting properties for fluid handling systems, wafer containers, and lab equipment to prevent contamination.

- If your primary focus is electrical integrity: Utilize PTFE as a high-performance dielectric insulator for high-frequency cables, circuit boards, and connectors to protect signal quality.

- If your primary focus is equipment reliability: Apply PTFE coatings to mechanical components in manufacturing lines, such as slide plates and gears, to reduce friction and wear.

By understanding these core functions, you can leverage PTFE to enhance both the reliability and purity of your sensitive electronic and semiconductor applications.

Summary Table:

| Application Area | Key Function of PTFE | Common Components |

|---|---|---|

| Semiconductor Fabrication | Chemical inertness & non-stick surface for purity | Wafer dippers, containers, labware |

| Electronics Manufacturing | Superior electrical insulation & dielectric strength | Circuit boards, connectors, high-frequency cables |

| Manufacturing Equipment | Low friction & corrosion resistance | Guide rails, slide pads, mechanical parts |

Enhance the purity and reliability of your sensitive applications with KINTEK's precision PTFE components.

Whether you are developing semiconductor fabrication tools, high-frequency electronics, or specialized industrial equipment, KINTEK manufactures high-quality PTFE seals, liners, and custom labware designed for extreme chemical resistance and superior electrical insulation. We offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact our experts today to discuss how our PTFE solutions can protect your process and products.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry