The definitive material for high-performance rotary shaft lip seals is Polytetrafluoroethylene (PTFE). Commonly known by its trade name Teflon, PTFE is the optimal choice due to its unique combination of extremely low friction, robust wear resistance, and the ability to withstand high temperatures and aggressive chemicals. This makes it a superior solution for demanding industrial applications.

While other materials are available, PTFE's inherent properties solve the core challenges of rotary sealing. Its combination of low friction and high resistance to chemicals and heat makes it the default choice for critical applications, ensuring longer equipment life and reducing operational costs.

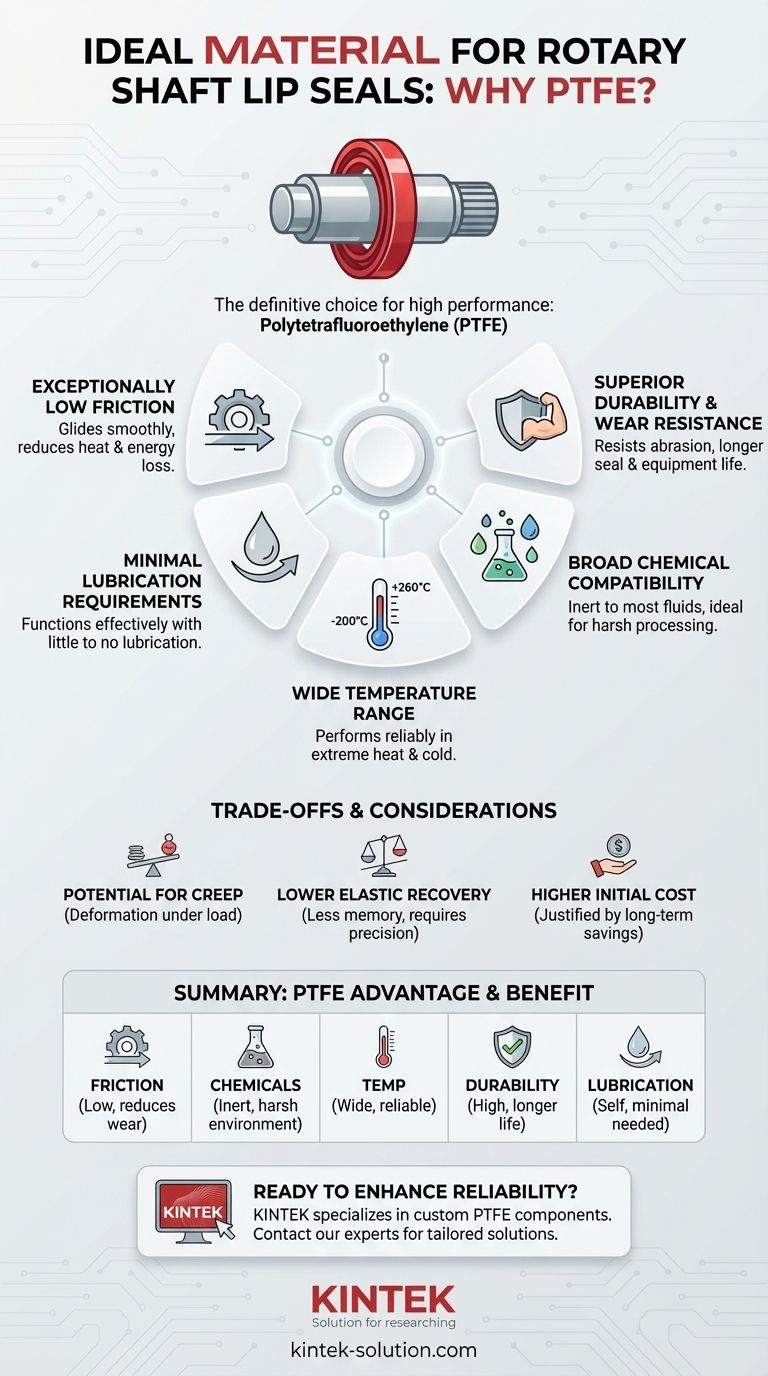

The Core Advantages of PTFE Seals

Understanding why PTFE is the preferred material requires examining its specific performance characteristics. Each attribute directly addresses a common failure point in rotating equipment.

Exceptionally Low Friction

PTFE possesses an extremely low coefficient of friction. This means the seal glides smoothly over the mating rotary shaft with minimal resistance.

This property is critical because it significantly reduces heat generation and energy loss, preventing premature seal failure and damage to the shaft itself.

Superior Durability and Wear Resistance

The low-friction nature of PTFE, combined with its inherent toughness, results in exceptional resistance to abrasion and wear.

This durability translates directly into a longer service life for both the seal and the equipment. The result is fewer maintenance cycles, less downtime, and lower long-term costs.

Broad Chemical Compatibility

PTFE is chemically inert, meaning it does not react with the vast majority of industrial fluids, solvents, and corrosive chemicals.

This makes PTFE seals the ideal choice for applications in chemical processing plants, where equipment like pumps and agitators are exposed to harsh substances that would degrade conventional seal materials.

Wide Operating Temperature Range

PTFE seals maintain their integrity and performance across a broad spectrum of operating temperatures.

They excel in high-temperature applications where traditional elastomeric seals would harden, crack, or lose their sealing capability.

Minimal Lubrication Requirements

A key advantage of PTFE is its ability to function effectively with minimal or even no lubrication.

This self-lubricating property makes it invaluable for applications where providing consistent lubrication is difficult or in systems where process fluids are non-lubricating.

Understanding the Trade-offs

While PTFE is a superior material, objectivity requires acknowledging its specific engineering considerations. It is not a universal replacement for all other seal types in every situation.

Potential for Creep

Like many polymers, PTFE can be susceptible to "creep" or "cold flow." This is a tendency to slowly deform over time when under a constant load, which can affect long-term sealing pressure. Seal design often incorporates fillers or spring energizers to mitigate this effect.

Lower Elastic Recovery

Compared to traditional rubber (elastomer) seals, PTFE is a more rigid material. It has less "memory" or elastic recovery.

This means that surface finish quality and precise installation are more critical for achieving a reliable seal. It is less forgiving of shaft imperfections than a highly flexible rubber seal.

Cost Considerations

High-performance materials command a higher price. PTFE seals typically have a higher initial cost than standard nitrile or viton seals.

However, this initial investment is often justified by the significant reduction in maintenance, downtime, and associated costs over the equipment's lifespan.

Making the Right Choice for Your Application

Your final decision should be guided by the specific demands of your operating environment.

- If your primary focus is reliability in harsh chemical or high-temperature environments: PTFE is the unparalleled choice due to its chemical inertness and thermal stability.

- If your primary focus is extending equipment life and reducing maintenance: PTFE's low friction and high wear resistance directly contribute to longer service intervals and less shaft damage.

- If you are working with high-speed, high-pressure, or poorly lubricated systems: The durability and low heat generation of PTFE seals make them the most dependable option.

Ultimately, selecting PTFE for your rotary shaft seals is an investment in your equipment's long-term performance and reliability.

Summary Table:

| Property | PTFE Advantage | Benefit for Your Application |

|---|---|---|

| Friction | Extremely Low Coefficient | Reduces heat, energy loss, and shaft wear |

| Chemical Resistance | Inert to Most Chemicals | Ideal for harsh chemical processing environments |

| Temperature Range | Wide Operating Range (-200°C to +260°C) | Performs reliably in high-heat applications |

| Durability | High Wear and Abrasion Resistance | Extends seal and equipment life, reduces downtime |

| Lubrication | Self-Lubricating | Functions effectively with minimal or no lubrication |

Ready to enhance your equipment's reliability with high-performance PTFE seals?

At KINTEK, we specialize in the precision manufacturing of custom PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a sealing solution tailored to your specific operational demands, from prototype to high-volume production.

Contact our experts today to discuss your application and receive a custom solution that maximizes performance and minimizes downtime.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What makes PTFE gaskets an ideal sealing material? Unmatched Chemical & Temperature Resistance

- Why are PTFE gaskets popular in various industries? Unmatched Chemical Resistance & Reliability

- What is a Teflon sheet and what is it made of? The Ultimate Guide to PTFE Material Properties

- What are the applications of PTFE in the chemical industry? A Guide to Superior Corrosion Resistance

- What are the main differences between virgin Teflon balls and glass-filled Teflon balls? Choose the Right PTFE for Your Application

- How is non-stick cookware coated with PTFE? The Science of a Slippery Surface

- What are the main industrial applications of PTFE impellers? Handling Corrosive & High-Purity Processes

- How does CNC machining enhance PTFE part production? Achieve Unmatched Precision & Efficiency