In short, PTFE impellers are predominantly used in chemical processing, pharmaceutical manufacturing, food and beverage production, and water treatment. Their selection is driven by an exceptional ability to handle highly corrosive chemicals and maintain absolute product purity, which is critical in these demanding industrial environments.

The decision to use a PTFE impeller is less about its mechanical properties and more about its chemical invincibility. It is the material of choice when the primary challenges are preventing corrosion and eliminating any risk of product contamination.

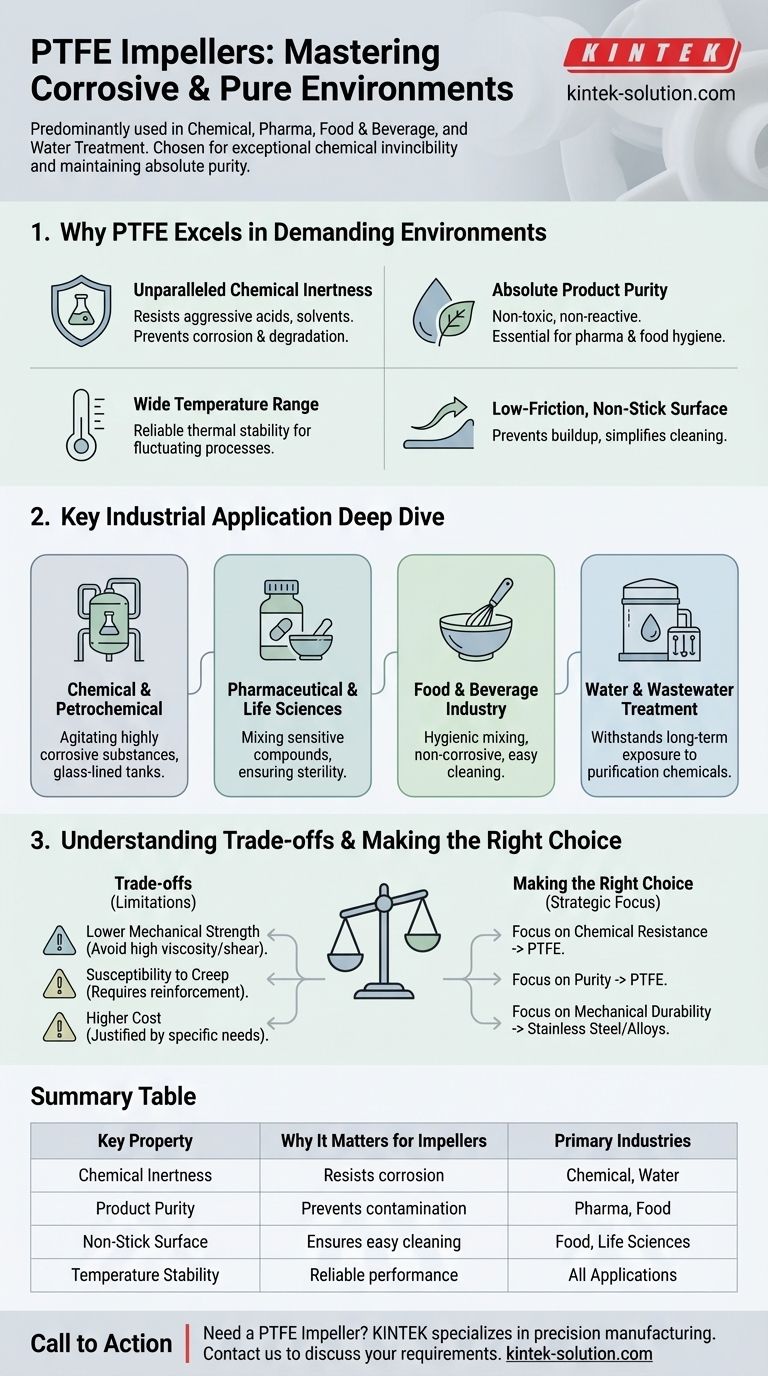

Why PTFE Excels in Demanding Environments

The value of a PTFE impeller is rooted in the unique molecular structure of Polytetrafluoroethylene. This structure gives it a combination of properties that are indispensable for specific industrial processes.

Unparalleled Chemical Inertness

PTFE is famously non-reactive. It offers near-universal resistance to a vast range of chemicals, including aggressive acids, solvents, oxidizing media, and petrochemicals.

This chemical stability ensures the impeller will not corrode, degrade, or leach unwanted substances into the process fluid, guaranteeing the longevity of the equipment.

Absolute Product Purity

In industries like pharmaceuticals and food production, preventing contamination is non-negotiable. PTFE is physiologically inert and non-toxic.

Because it does not react with or adhere to the materials it is mixing, it ensures the final product remains pure and meets strict regulatory and hygiene standards.

Wide Operational Temperature Range

PTFE maintains its integrity across a broad spectrum of temperatures, from very low to high.

This thermal stability allows it to be used reliably in processes that involve significant temperature fluctuations without becoming brittle or deforming.

Low-Friction, Non-Stick Surface

The well-known "non-stick" quality of PTFE provides a functional advantage for impellers.

This low-friction surface helps prevent viscous materials or solids from building up on the blades, ensuring more consistent mixing efficiency and simplifying cleaning procedures.

Key Industrial Application Deep Dive

While many materials can be used for impellers, PTFE is specified when the process conditions are too harsh for conventional plastics or metals.

Chemical and Petrochemical Processing

This is the primary application for PTFE impellers. They are used in reactors, mixing tanks, and columns, especially those that are glass-lined.

They are essential for agitating highly corrosive substances where even high-grade stainless steel or specialty alloys would fail over time.

Pharmaceutical and Life Sciences

In the manufacturing of active pharmaceutical ingredients (APIs) and other medical products, sterility is paramount.

PTFE impellers are used to mix sensitive compounds without introducing impurities. Their inertness guarantees that the chemical composition of the final product is not altered.

Food and Beverage Industry

The non-corrosive and non-toxic nature of PTFE makes it ideal for food processing applications.

It is used for mixing ingredients where hygiene is critical, and its non-stick properties facilitate easy and thorough cleaning between batches to prevent cross-contamination.

Water and Wastewater Treatment

Water purification processes often rely on powerful chemicals like chlorine, ozone, or various acids and bases to remove contaminants.

PTFE impellers can withstand long-term exposure to these chemicals without degrading, making them a reliable choice for mixing tanks in treatment plants.

Understanding the Trade-offs

Despite its powerful advantages, PTFE is not universally applicable. Understanding its limitations is key to making an informed decision.

Lower Mechanical Strength

Compared to stainless steel or other metal alloys, PTFE is a much softer material.

It is not suitable for applications involving high-viscosity fluids, heavy slurries, or conditions with high shear stress that demand significant mechanical strength and rigidity.

Susceptibility to Creep

Under sustained mechanical load and elevated temperatures, PTFE can slowly deform over time, a phenomenon known as "creep."

This must be accounted for in the impeller's structural design, often by reinforcing it with a metal core, to ensure it maintains its shape and balance throughout its service life.

Cost Considerations

While PTFE products are often described as affordable for their capabilities, they can be more expensive than standard polymers or some metals.

Its use must be justified by the absolute need for chemical resistance or purity that other materials cannot provide.

Making the Right Choice for Your Application

Selecting the right impeller material is a strategic choice based on the primary challenge of your process.

- If your primary focus is handling highly corrosive chemicals: PTFE is the default choice for ensuring equipment longevity and preventing catastrophic failure.

- If your primary focus is maintaining absolute product purity: PTFE's inertness is essential for any pharmaceutical, food-grade, or high-purity chemical application where contamination is unacceptable.

- If your primary focus is high-viscosity mixing or abrasive media: You should evaluate impellers made from stainless steel, high-strength alloys, or reinforced polymers that offer superior mechanical durability.

Ultimately, choosing a PTFE impeller is a deliberate engineering decision to prioritize chemical compatibility and purity above all other performance metrics.

Summary Table:

| Key Property | Why It Matters for Impellers | Primary Industries |

|---|---|---|

| Chemical Inertness | Resists corrosion from acids, solvents, and aggressive media. | Chemical Processing, Water Treatment |

| Product Purity | Non-toxic and non-reactive, prevents contamination. | Pharmaceutical, Food & Beverage |

| Non-Stick Surface | Prevents material buildup, ensures easy cleaning. | Food & Beverage, Life Sciences |

| Temperature Stability | Performs reliably across a wide temperature range. | All Major Applications |

Need a PTFE Impeller for Your Demanding Application?

When your process demands unmatched corrosion resistance and absolute product purity, the right PTFE component is critical. KINTEK specializes in the precision manufacturing of high-performance PTFE impellers and other custom components for the semiconductor, medical, laboratory, and industrial sectors.

We partner with you from prototype to high-volume production to ensure your equipment meets the highest standards of durability and hygiene.

Contact us today to discuss your specific requirements: Get in Touch

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech