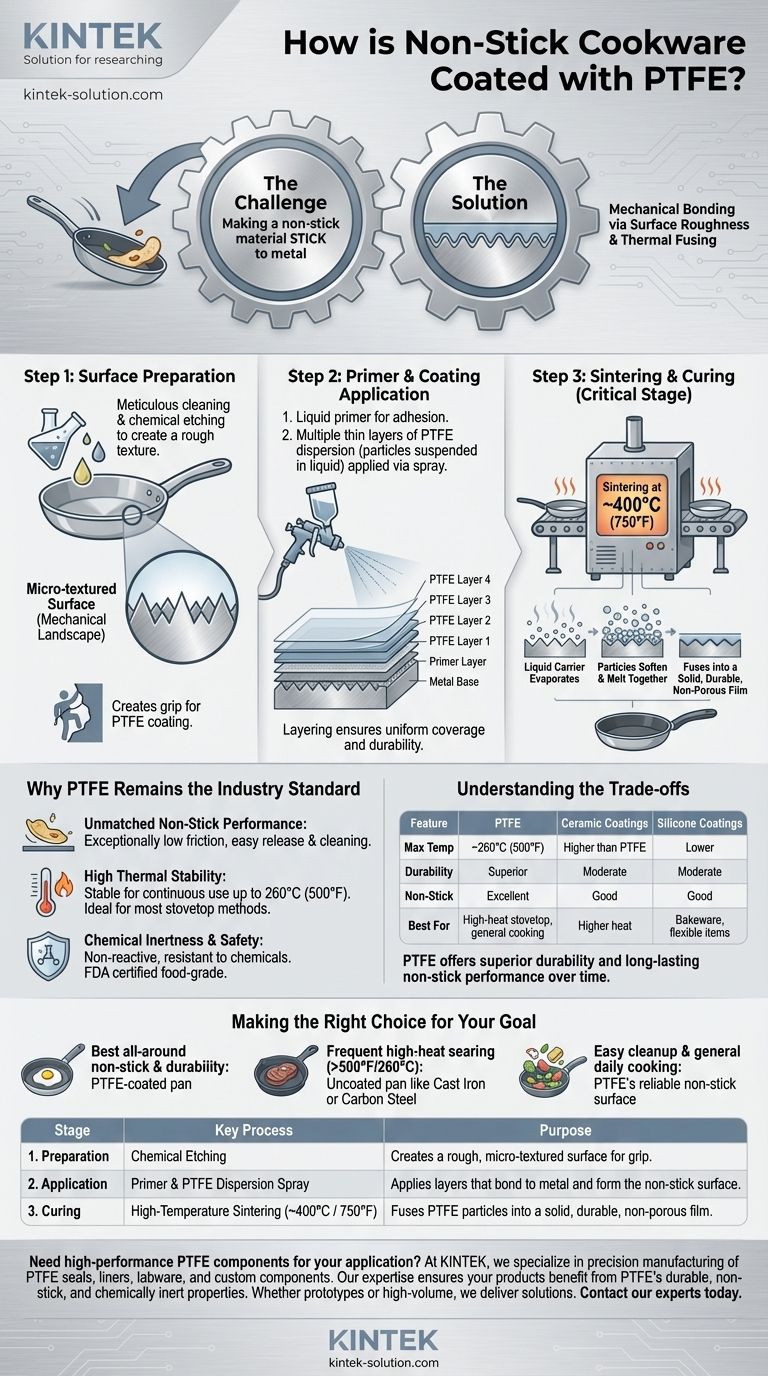

At its core, the process of coating cookware with Polytetrafluoroethylene (PTFE) is a multi-stage industrial method designed to fuse a non-stick polymer onto a metal base. The metal surface is first chemically etched to create a rough texture, then multiple layers of a liquid PTFE dispersion are applied and finally cured at high temperatures to form a durable, solid film.

The essential challenge is making a material famous for not sticking stick to a metal pan. The solution involves physically roughening the metal surface and then thermally fusing the PTFE into that texture, creating a strong mechanical bond.

The Engineering Behind the Bond

To appreciate the process, you must first understand the fundamental problem: PTFE does not bond easily to other materials. The entire coating procedure is engineered to overcome this inherent property and create a lasting non-stick surface.

Step 1: Surface Preparation

The process begins by preparing the pan's base metal, typically aluminum or stainless steel. The surface is meticulously cleaned and then chemically etched, often using a solution of hydrochloric and nitric acid. This etching process doesn't smooth the surface; it does the opposite, creating microscopic peaks and valleys.

This roughened texture is the key. It provides a greater surface area and a mechanical landscape for the PTFE coating to grip onto, much like a rock climber needs holds on a cliff face.

Step 2: Primer and Coating Application

Once the surface is prepared, a liquid primer is applied. This primer is designed to adhere well to the metal and also provide a compatible base for the subsequent PTFE layers.

Next, the PTFE itself is applied. It isn't a paint but a dispersion—tiny particles of PTFE suspended in a liquid carrier. This dispersion is typically spray-coated onto the pan in multiple thin layers. Building the coating in layers is critical for ensuring uniform coverage and overall durability.

Step 3: Sintering and Curing

This is the most critical stage. After the layers are applied, the cookware is sent through high-temperature ovens in a process called sintering.

The heat causes two things to happen. First, the liquid carrier evaporates. Second, as the temperature rises (often to around 400°C or 750°F), the individual PTFE particles soften and melt together. They flow into the microscopic crevices created by the etching and fuse into a single, solid, non-porous film that is mechanically locked onto the pan's surface.

Why PTFE Remains the Industry Standard

While other non-stick technologies exist, PTFE's unique combination of properties makes it exceptionally well-suited for cookware.

Unmatched Non-Stick Performance

PTFE has one of the lowest coefficients of friction of any known solid. This gives it the exceptionally slippery, waxy feel that prevents food from sticking. This property also makes it incredibly easy to clean.

High Thermal Stability

PTFE is stable for continuous use at temperatures up to 260°C (500°F). This covers almost all stovetop cooking methods, from frying to sautéing. It only begins to degrade at significantly higher temperatures.

Chemical Inertness and Safety

PTFE is extremely non-reactive and is resistant to a wide range of chemicals. It is certified as food-grade by regulatory bodies like the FDA, confirming its safety for food contact when used as intended.

Understanding the Trade-offs

No material is perfect for every application. Understanding where PTFE stands in relation to alternatives is key to making an informed choice.

PTFE vs. Ceramic Coatings

Ceramic non-stick coatings can typically withstand higher temperatures than PTFE. However, PTFE coatings generally offer superior durability, chemical resistance, and a longer-lasting non-stick performance over time.

PTFE vs. Silicone Coatings

Silicone is a flexible material often used for bakeware. While it has good non-stick properties, PTFE provides better non-stick release and significantly higher temperature stability, making it the superior choice for high-heat stovetop cooking.

Making the Right Choice for Your Goal

The right cookware depends entirely on your primary cooking style and priorities.

- If your primary focus is the best all-around non-stick performance and durability: A well-made PTFE-coated pan is the established industry leader.

- If your primary focus is frequent high-heat searing above 500°F (260°C): An uncoated pan like cast iron or carbon steel is the most suitable tool for the job.

- If your primary focus is easy cleanup and general-purpose daily cooking: PTFE's reliable non-stick surface remains the most practical and effective option.

Ultimately, understanding how your cookware is made empowers you to use it more effectively and choose the right tool for your kitchen.

Summary Table:

| Stage | Key Process | Purpose |

|---|---|---|

| 1. Preparation | Chemical Etching | Creates a rough, micro-textured surface for the PTFE to grip. |

| 2. Application | Primer & PTFE Dispersion Spray | Applies layers that bond to metal and form the non-stick surface. |

| 3. Curing | High-Temperature Sintering (~400°C / 750°F) | Fuses PTFE particles into a solid, durable, non-porous film. |

Need high-performance PTFE components for your application?

At KINTEK, we specialize in the precision manufacturing of PTFE seals, liners, labware, and custom components. Our expertise in material science and custom fabrication ensures your products benefit from the same durable, non-stick, and chemically inert properties that make PTFE the industry standard. Whether you need prototypes or high-volume orders for the semiconductor, medical, laboratory, or industrial sectors, we deliver solutions built to perform.

Contact our experts today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- In which industries are PTFE rotary shaft seals commonly used? The Standard for Extreme Conditions

- What advantages do the low friction and non-stick properties of PTFE gaskets provide? Boost System Reliability and Purity

- What are the features of Polytetrafluoroethylene (PTFE) with Mineral Fill? Achieve Superior Durability in Demanding Applications

- What are the durability benefits of PTFE washers? Achieve Unmatched Chemical & Thermal Resistance

- What are the available configurations for PTFE envelope gaskets? Engineer the Perfect Seal for Your Application

- What makes PTFE the preferred choice for high-speed rotary shaft seals? Unmatched Performance in Demanding Applications

- What alternative material is gaining popularity for hydrogenerator thrust bearings? PTFE for Superior Performance & Reliability

- Why is Teflon packing popular in chemical and heat-sensitive environments? For Unmatched Chemical Resistance and Low Friction