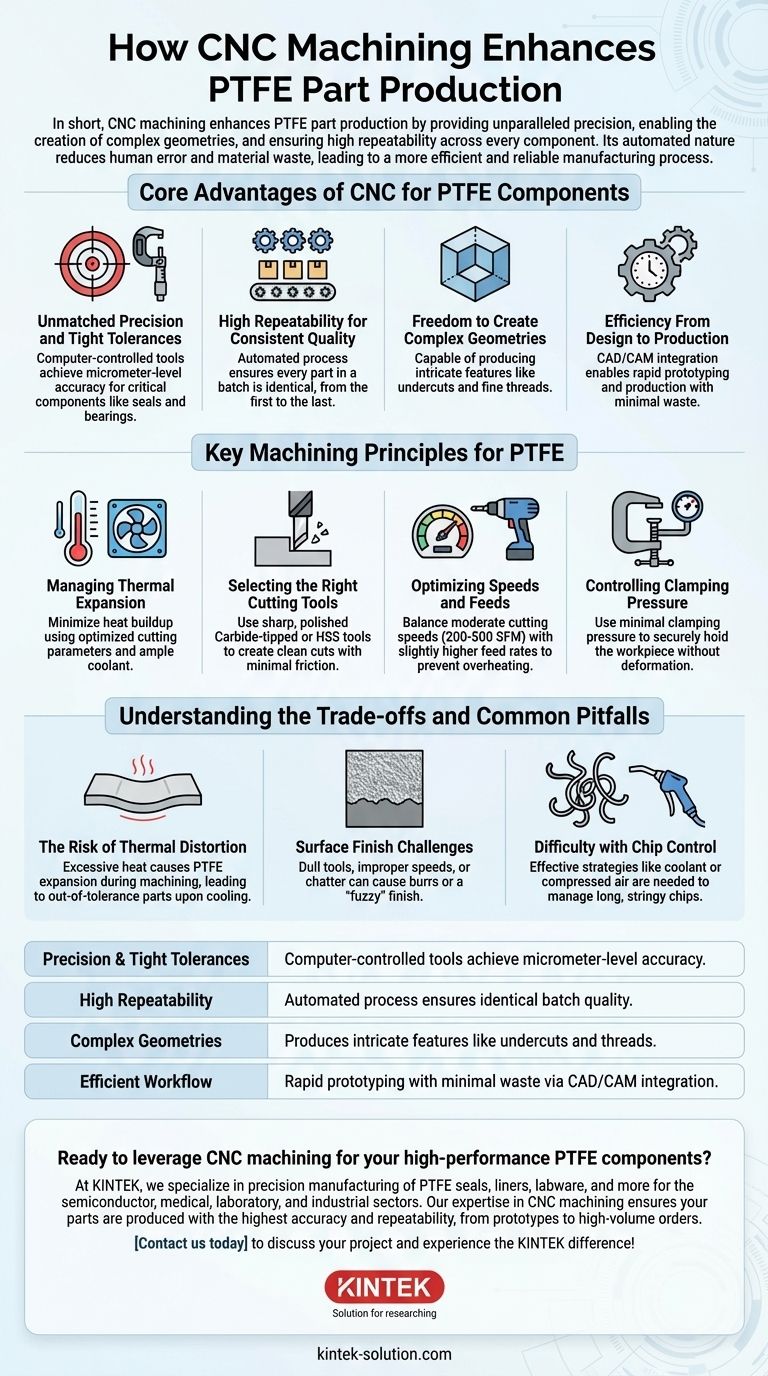

In short, CNC machining enhances PTFE part production by providing unparalleled precision, enabling the creation of complex geometries, and ensuring high repeatability across every component. Its automated nature reduces human error and material waste, leading to a more efficient and reliable manufacturing process.

The core challenge in working with Polytetrafluoroethylene (PTFE) is its unique combination of softness and high thermal expansion. CNC machining excels because it offers precise, computer-driven control over every variable—from cutting speed to tool pressure—needed to manage these properties and produce dimensionally accurate parts consistently.

The Core Advantages of CNC for PTFE Components

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses computer-controlled tools to remove material from a solid block of PTFE. This method systematically overcomes the limitations of traditional molding or manual machining.

Unmatched Precision and Tight Tolerances

Computer control allows for movements measured in micrometers. This precision is essential for creating high-performance PTFE parts like seals, gaskets, and bearings, where even minor dimensional inaccuracies can lead to failure.

High Repeatability for Consistent Quality

Once a program is perfected, a CNC machine can produce thousands of identical parts with no deviation. This automation ensures that the last part in a batch is of the exact same quality and dimension as the first, a critical requirement for industrial applications.

Freedom to Create Complex Geometries

Traditional manufacturing methods struggle with intricate designs. CNC machining can execute complex tool paths to create features like undercuts, fine threads, and unique contours that would otherwise be impossible or prohibitively expensive to produce.

Efficiency From Design to Production

The integration of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software streamlines the entire workflow. Designs can be quickly translated into machine instructions, allowing for rapid prototyping and faster production cycles with minimal material waste.

Key Machining Principles for PTFE

Successfully machining PTFE is less about raw power and more about finesse. The material's properties demand a specific approach to avoid common failures like melting, distortion, and poor surface finish.

Managing Thermal Expansion

PTFE expands significantly when heated, which can ruin dimensional accuracy. The primary goal is to minimize heat buildup by using optimized cutting parameters and, when necessary, an ample supply of coolant.

Selecting the Right Cutting Tools

The tools must be extremely sharp and polished. Carbide-tipped or High-Speed Steel (HSS) tools are preferred because they create clean cuts with minimal friction, which in turn reduces heat generation. A dull tool will plow through the material rather than shear it, causing melting and a poor finish.

Optimizing Speeds and Feeds

Finding the right balance of cutting speed and feed rate is crucial.

- Cutting Speed: Generally, moderate cutting speeds (often between 200-500 surface feet per minute) are used to prevent overheating and melting the material at the cutting edge.

- Feed Rate: A slightly higher feed rate can help by moving the tool through the material quickly, preventing it from dwelling in one spot and building up excessive heat.

Controlling Clamping Pressure

PTFE is a soft material that can easily be compressed or distorted. It is critical to use minimal clamping pressure in fixtures to hold the workpiece securely without deforming it, which would lead to an inaccurate final part.

Understanding the Trade-offs and Common Pitfalls

While highly effective, CNC machining of PTFE is not without its challenges. Understanding these potential issues is key to achieving a successful outcome.

The Risk of Thermal Distortion

This is the most common failure point. If speeds are too high or tooling is incorrect, the generated heat will cause the PTFE to expand during machining. When the part cools, it will contract to a size that is out of tolerance.

Surface Finish Challenges

Because PTFE is soft, it can be prone to burrs or a "fuzzy" surface finish if not machined correctly. This is almost always a result of a dull tool, improper speeds, or chatter from excessive vibration.

Difficulty with Chip Control

PTFE produces long, stringy chips that can wrap around the cutting tool and workpiece. An effective machining strategy, often involving a jet of coolant or compressed air, is needed to clear these chips and prevent them from interfering with the cut or marring the part's surface.

Making the Right Choice for Your Application

Leveraging CNC for your PTFE components depends on aligning the process capabilities with your project's specific goals.

- If your primary focus is high-volume production: CNC machining is the ideal choice for its exceptional repeatability and automated efficiency, ensuring every part meets specification.

- If your primary focus is prototyping and rapid design iteration: The direct link between CAD software and CNC machines allows you to make fast, affordable design changes and test new concepts quickly.

- If your primary focus is creating complex parts with critical tolerances: CNC machining is often the only viable method for achieving the required geometric complexity and dimensional accuracy in PTFE.

By mastering these principles, CNC machining provides a reliable and precise path to manufacturing high-performance PTFE components.

Summary Table:

| Advantage | Description |

|---|---|

| Precision & Tight Tolerances | Computer-controlled tools achieve micrometer-level accuracy for critical components. |

| High Repeatability | Automated process ensures every part in a batch is identical. |

| Complex Geometries | Capable of producing intricate features like undercuts and fine threads. |

| Efficient Workflow | CAD/CAM integration enables rapid prototyping and production with minimal waste. |

Ready to leverage CNC machining for your high-performance PTFE components?

At KINTEK, we specialize in precision manufacturing of PTFE seals, liners, labware, and more for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in CNC machining ensures your parts are produced with the highest accuracy and repeatability, from prototypes to high-volume orders.

Contact us today to discuss your project and experience the KINTEK difference!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers