In the chemical industry, Polytetrafluoroethylene (PTFE) is a cornerstone material used for a vast range of applications due to its unparalleled chemical resistance. Key uses include protective coatings and linings for vessels and pipes, high-integrity seals and gaskets for preventing leaks, and critical components within pumps and valves that handle corrosive fluids.

The core challenge in the chemical industry is safely containing and processing highly aggressive substances. PTFE's value lies in its ability to function as a complete, chemically inert system—from the lining of a reaction vessel to the seal in a pump—ensuring operational integrity and safety.

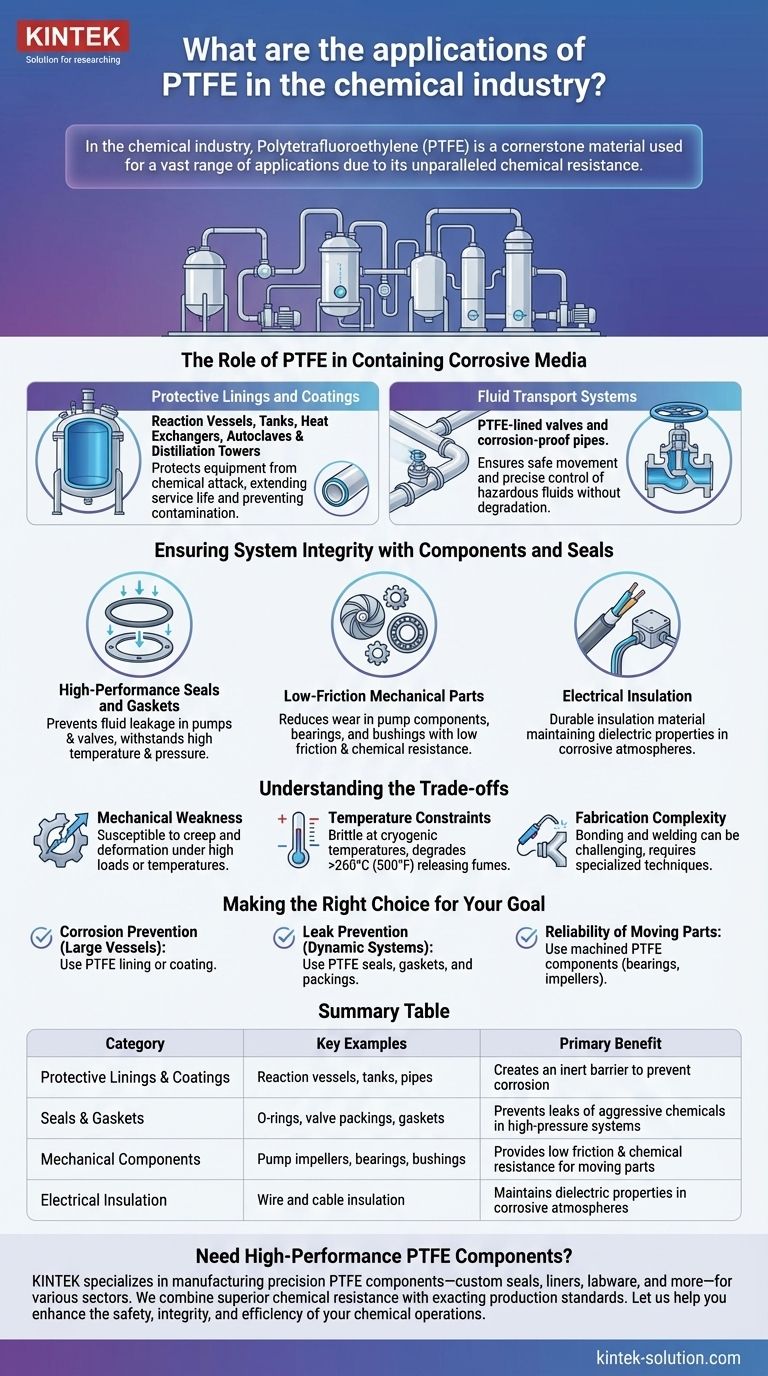

The Role of PTFE in Containing Corrosive Media

The primary function of PTFE in chemical processing is to create a barrier between aggressive chemicals and the structural materials of the equipment, which are often metals susceptible to corrosion.

Protective Linings and Coatings

PTFE is applied as a lining or coating to a wide array of critical equipment. This protects the underlying steel or other alloys from chemical attack.

This application is common for reaction vessels, tanks, heat exchangers, autoclaves, and distillation towers, extending their service life and preventing product contamination.

Fluid Transport Systems

For safely moving corrosive materials, PTFE is indispensable. It is used to create corrosion-proof pipes, valves, and pipe fittings.

PTFE-lined valves are particularly critical, as they allow for the precise control of hazardous fluids without risk of the valve itself degrading or failing from chemical exposure.

Ensuring System Integrity with Components and Seals

Beyond static containment, PTFE is machined into essential components that must function reliably within harsh chemical environments.

High-Performance Seals and Gaskets

One of the most common uses for PTFE is in sealing applications. PTFE O-rings, gaskets, and packings are used to prevent fluid leakage in high-pressure and high-temperature systems.

These seals are essential for equipment like pumps and valves, where they provide shaft sealing to contain aggressive chemicals and protect the system from failure.

Low-Friction Mechanical Parts

PTFE's low coefficient of friction, combined with its chemical inertness, makes it ideal for moving parts.

It is frequently used for pump components like impellers and diaphragms, as well as for bearings and bushings. This reduces wear, improves efficiency, and ensures the parts are not degraded by the chemicals they interact with.

Electrical Insulation

In chemical plants, electrical components often exist in corrosive atmospheres. PTFE is used as a durable insulation material that can withstand chemical exposure without losing its dielectric properties.

Understanding the Trade-offs

While chemically superior, PTFE is not a universal solution. Its physical properties introduce specific limitations that engineers must consider.

Mechanical Weakness

Compared to metals, PTFE is a relatively soft material. It can be susceptible to creep and deformation, especially under high mechanical loads or at elevated temperatures. This limits its use as a primary structural material.

Temperature Constraints

Although it has a wide operating temperature range, PTFE has firm limits. It can become brittle at cryogenic temperatures and can begin to degrade at temperatures exceeding approximately 260°C (500°F), releasing harmful fumes.

Fabrication Complexity

Bonding PTFE to other surfaces or welding it can be challenging. Applying PTFE linings often requires specialized surface preparation and fabrication techniques to ensure a durable and seamless bond.

Making the Right Choice for Your Goal

To leverage PTFE effectively, you must align the application with its core strengths.

- If your primary focus is corrosion prevention for large vessels: A PTFE lining or coating is the most effective solution to protect the structural integrity of your equipment.

- If your primary focus is preventing leaks in dynamic systems: PTFE seals, gaskets, and valve packings provide reliable containment for aggressive fluids, especially under pressure.

- If your primary focus is improving the reliability of moving parts: Machined PTFE components like bearings, pump impellers, and bushings simultaneously reduce friction and resist chemical attack.

Ultimately, integrating PTFE strategically across your system protects not just the individual pieces of equipment, but the safety and efficiency of the entire chemical process.

Summary Table:

| Application Category | Key Examples | Primary Benefit |

|---|---|---|

| Protective Linings & Coatings | Reaction vessels, tanks, pipes | Creates an inert barrier to prevent corrosion of equipment |

| Seals & Gaskets | O-rings, valve packings, gaskets | Prevents leaks of aggressive chemicals in high-pressure systems |

| Mechanical Components | Pump impellers, bearings, bushings | Provides low friction and chemical resistance for moving parts |

| Electrical Insulation | Wire and cable insulation | Maintains dielectric properties in corrosive atmospheres |

Need High-Performance PTFE Components for Your Chemical Process?

KINTEK specializes in manufacturing precision PTFE components—including custom seals, liners, labware, and more—for the semiconductor, medical, laboratory, and industrial sectors. We combine superior chemical resistance with exacting production standards, from prototype development to high-volume orders.

Let us help you enhance the safety, integrity, and efficiency of your chemical operations.

Contact us today to discuss your specific requirements and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments