At their core, Teflon bushings are suitable for food and pharmaceutical applications because they are inherently self-lubricating and chemically inert. This unique combination eliminates the need for external oils or greases—a primary source of contamination—while also ensuring the bushing material itself does not react with or leach into the sensitive products it contacts.

The suitability of Teflon isn't just about a single feature; it's about how its properties work together to create a system that inherently minimizes contamination risk, satisfying the stringent purity and safety demands of the food and pharmaceutical industries.

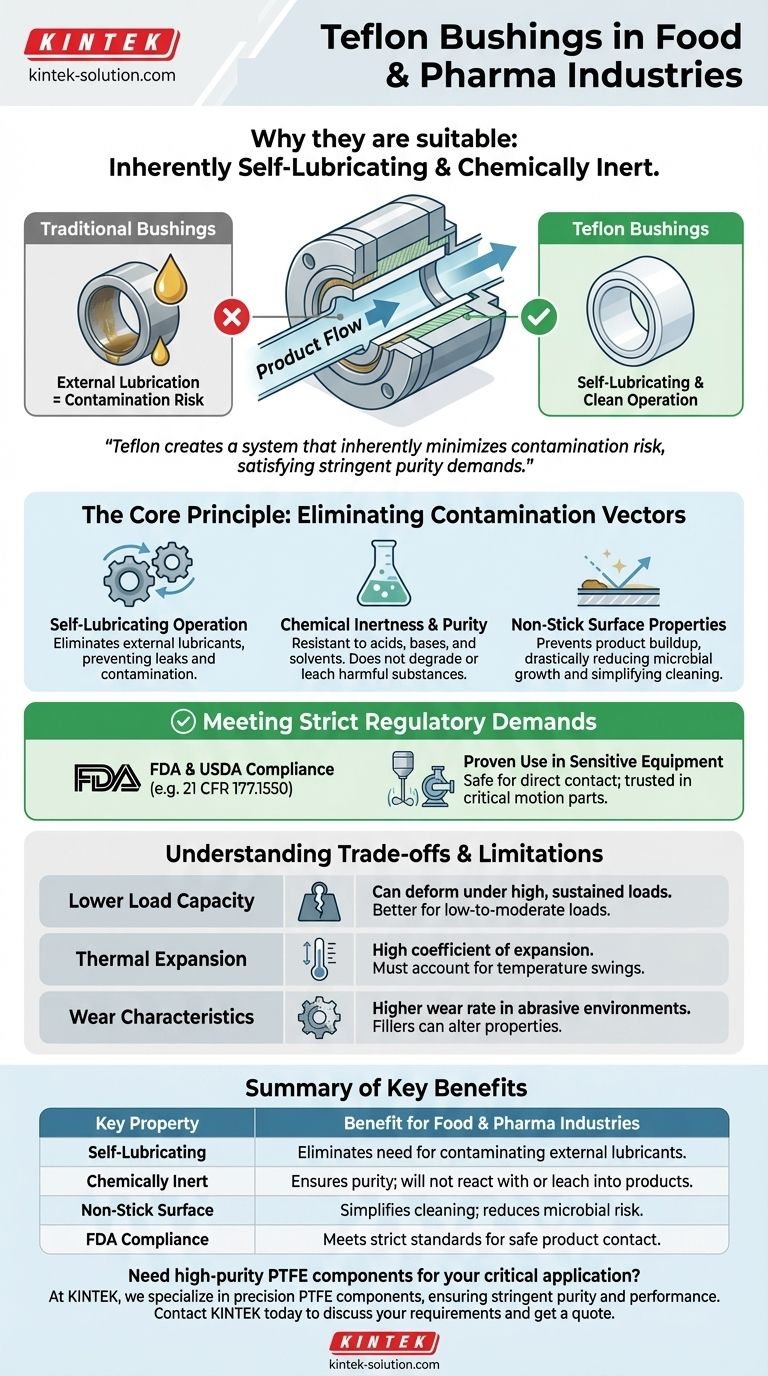

The Core Principle: Eliminating Contamination Vectors

The primary goal in any food or pharmaceutical processing line is to protect product purity. Teflon (PTFE) bushings contribute directly to this by removing common points where contaminants are introduced.

Self-Lubricating Operation

Traditional bushings require external lubricants like oil or grease to reduce friction and wear. These substances can easily leak, drip, or migrate, causing direct product contamination.

Teflon’s extremely low coefficient of friction allows it to function as a bearing surface without any external lubrication. This design immediately eliminates a major contamination vector from the machinery.

Chemical Inertness and Purity

Teflon is one of the most non-reactive materials known. It does not react with acids, bases, solvents, or the complex chemical compounds found in food and drug products.

This inertness guarantees that the bushing material itself will not degrade, corrode, or leach harmful substances into the product stream, ensuring its purity and safety.

Non-Stick Surface Properties

The famous non-stick quality of Teflon also plays a critical role. This property prevents product residue, ingredients, or biological matter from adhering to the bushing surface.

A surface free from buildup is far easier to clean and sanitize effectively, drastically reducing the risk of microbial growth and cross-contamination between batches.

Meeting Strict Regulatory Demands

Beyond its physical properties, Teflon's ability to meet government and industry standards is a non-negotiable requirement for its use in these sectors.

FDA and USDA Compliance

Specific grades of Teflon (PTFE) are manufactured to comply with FDA regulations, particularly 21 CFR 177.1550. This standard certifies that the material is safe for direct contact with food.

This official compliance provides a necessary assurance for auditors, quality control managers, and engineers that the material is non-toxic, non-allergenic, and suitable for its intended use.

Proven Use in Sensitive Equipment

This combination of compliance and performance is why Teflon bushings are widely trusted in critical motion parts.

You will find them in mixers, dispensers, pumps, and guides where maintaining a clean, unadulterated contact surface between moving parts and the product is paramount.

Understanding the Trade-offs and Limitations

While highly effective, Teflon is not a universal solution. An objective technical assessment requires understanding its operational limits.

Lower Load Capacity

Compared to metallic bushings (like bronze or steel), Teflon is a softer material. It can deform or "creep" under high, sustained loads. Applications involving heavy machinery or high impact forces may require a different material.

Thermal Expansion

Teflon has a relatively high coefficient of thermal expansion. In equipment that experiences wide temperature swings, such as from steam cleaning cycles, designers must account for how the bushing will expand and contract to maintain proper clearances and avoid seizure.

Wear Characteristics

While self-lubricating, pure Teflon can exhibit a higher rate of wear compared to harder materials, especially in abrasive environments. To counteract this, manufacturers often add fillers (like glass or carbon), but this can alter the material's chemical resistance and regulatory compliance, requiring careful evaluation.

Making the Right Choice for Your Application

Selecting the correct bushing material depends entirely on balancing performance requirements with safety mandates.

- If your primary focus is preventing product contamination and ensuring regulatory compliance: Teflon's self-lubrication and chemical inertness make it an ideal choice for low-to-moderate load applications.

- If your primary focus is handling high mechanical loads or abrasive conditions: You must carefully evaluate if a filled-PTFE compound meets your needs or if a fundamentally different material, like a food-grade metallic bearing, is required.

By understanding these core material properties and their trade-offs, you can confidently select a bushing that ensures both operational reliability and absolute product safety.

Summary Table:

| Key Property | Benefit for Food & Pharma Industries |

|---|---|

| Self-Lubricating | Eliminates need for contaminating external lubricants like grease or oil. |

| Chemically Inert | Will not react with or leach into sensitive products, ensuring purity. |

| Non-Stick Surface | Prevents residue buildup, simplifying cleaning and reducing microbial risk. |

| FDA Compliance | Meets strict standards (e.g., 21 CFR 177.1550) for safe product contact. |

Need high-purity PTFE components for your critical application?

At KINTEK, we specialize in manufacturing precision PTFE components, including seals, liners, and custom bushings, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components meet the stringent purity and performance demands of the food and pharmaceutical industries.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision and compliance. Let us help you ensure product safety and operational reliability.

Contact KINTEK today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What scientific research supports the use of PTFE Liners in medical devices? Proven Benefits for Safety & Performance

- What are the key differences between PTFE and EPDM valve seats? Choose the Right Material for Your Application

- In what scenarios are PTFE bellows not the best choice? Avoid System Failure by Understanding PTFE's Limits

- What does the material compatibility chart indicate about PTFE? A Guide to Its Broad Chemical Resistance

- How does the chemical resistance of PTFE gaskets benefit industrial applications? Achieve Unmatched Reliability

- How do PTFE slide bearings compare to traditional expansion plates? Superior Performance & Lower Lifetime Cost

- What are the advantages of PTFE rotary shaft lip seals? Superior Performance in Extreme Conditions

- What other machinable plastics are used for lip seals besides PTFE? Explore High-Performance Alternatives