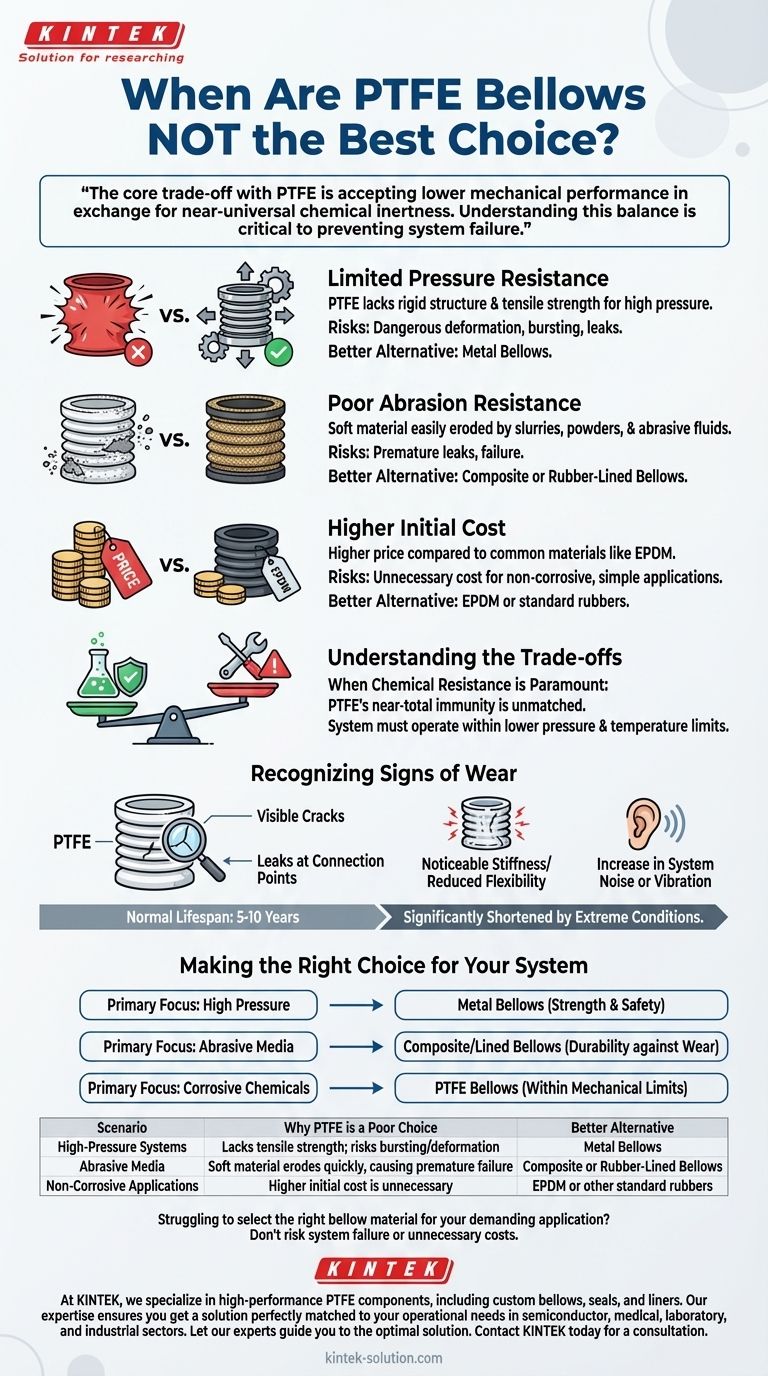

While prized for their exceptional chemical resistance, PTFE bellows are fundamentally unsuitable for applications involving high pressure or abrasive materials. Their inherent lack of mechanical strength and poor abrasion resistance makes them a point of failure in systems where these forces are significant.

The core trade-off with PTFE is accepting lower mechanical performance in exchange for near-universal chemical inertness. Understanding this balance is critical to preventing system failure.

Key Weaknesses of PTFE Bellows

To determine if PTFE is the wrong choice, you must evaluate its performance against three key physical demands: pressure, abrasion, and cost.

Limited Pressure Resistance

PTFE is a fluoropolymer, not a metal. It lacks the rigid structure and tensile strength to withstand high-pressure environments.

Exceeding its pressure rating can lead to dangerous deformation, bursting, or catastrophic failure of the bellow, causing leaks and system downtime. For high-pressure applications, metal bellows are the industry standard.

Poor Abrasion Resistance

PTFE is a relatively soft material that is easily damaged by friction from hard particles.

If your system transports slurries, powders, or fluids with suspended solids, these abrasive particles will quickly erode the bellow walls. This erosion leads to premature leaks and failure. Composite or rubber-lined bellows offer far superior durability in these scenarios.

Higher Initial Cost

Compared to more common materials like EPDM or other rubbers, PTFE components often carry a higher price tag.

While its unique properties can justify the cost in corrosive environments, it is an unnecessarily expensive choice for simple applications where chemical resistance is not the primary concern.

Understanding the Trade-offs

Choosing the right bellow is not about finding a universally perfect material, but about selecting the one whose strengths align with your specific challenge.

When Chemical Resistance is Paramount

Despite its weaknesses, PTFE's near-total immunity to chemical attack is unmatched.

For systems handling highly aggressive acids, solvents, or other corrosive media, PTFE is often the only viable option. In these cases, the system must be designed to operate within the bellow's lower pressure and temperature limits.

Recognizing Signs of Wear

Understanding a material's failure modes is key to preventative maintenance. Wear in PTFE bellows often manifests physically before a complete failure.

Key indicators include visible cracks, leaks at connection points, noticeable stiffness or reduced flexibility, and an increase in system noise or vibration. Under normal conditions, a 5-10 year lifespan is typical, but this is significantly shortened by extreme temperatures, pressures, or frequent cycling.

Making the Right Choice for Your System

To select the correct component, evaluate your system's primary operational demands.

- If your primary focus is handling high pressure: Metal bellows provide the necessary mechanical strength and safety factor.

- If your primary focus is transporting abrasive media: Choose composite or specially lined bellows designed for high durability against wear.

- If your primary focus is containing highly corrosive chemicals: PTFE is the superior choice, as long as the system operates within its mechanical limits.

Ultimately, selecting the right expansion joint requires matching the material's properties directly to the operational challenge at hand.

Summary Table:

| Scenario | Why PTFE is a Poor Choice | Better Alternative |

|---|---|---|

| High-Pressure Systems | Lacks tensile strength; risks bursting or deformation | Metal Bellows |

| Abrasive Media (slurries, powders) | Soft material erodes quickly, causing premature failure | Composite or Rubber-Lined Bellows |

| Non-Corrosive, Simple Applications | Higher initial cost is unnecessary | EPDM or other standard rubbers |

Struggling to select the right bellow material for your demanding application? Don't risk system failure or unnecessary costs.

At KINTEK, we specialize in high-performance PTFE components, including custom bellows, seals, and liners. Our expertise ensures you get a solution perfectly matched to your operational needs—whether you're in the semiconductor, medical, laboratory, or industrial sector. We provide precision manufacturing from prototypes to high-volume orders.

Let our experts guide you to the optimal solution. Contact KINTEK today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications