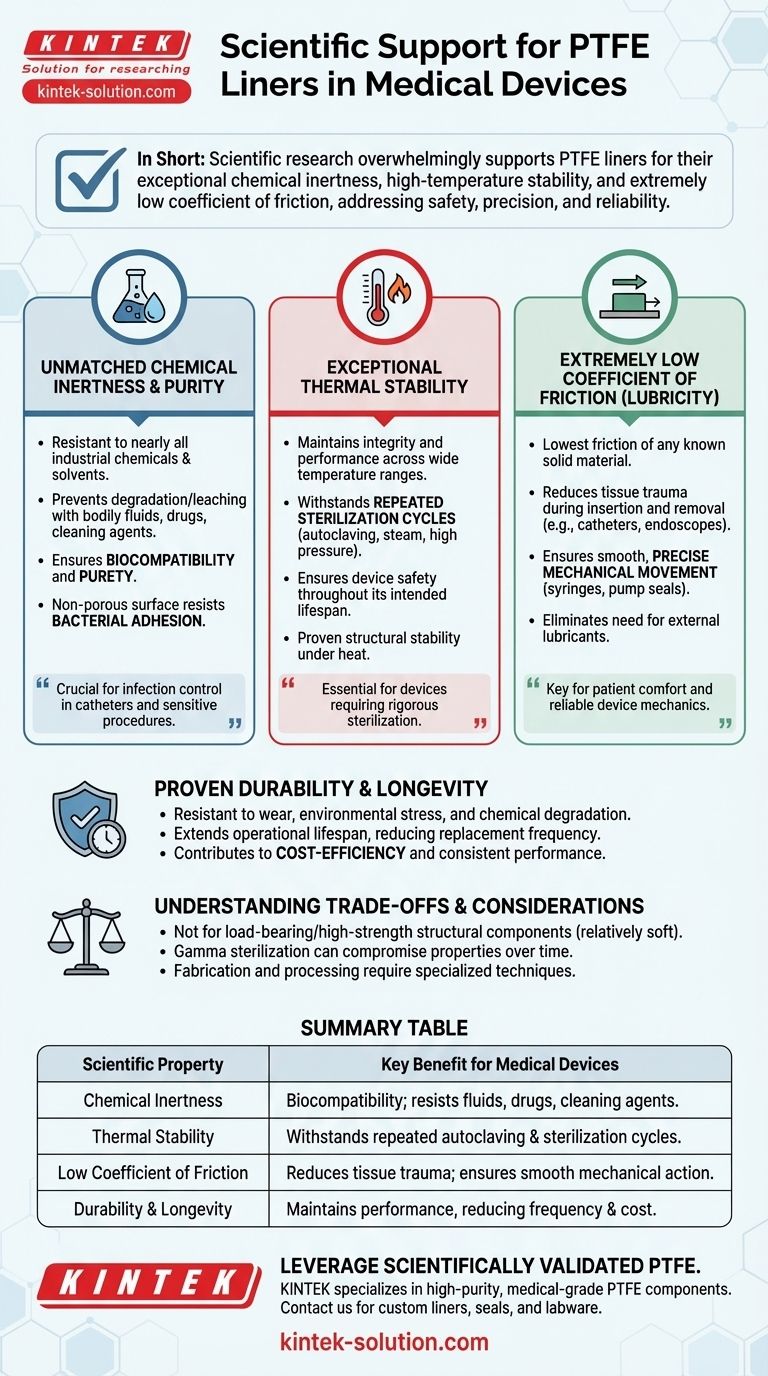

In short, scientific research overwhelmingly supports the use of PTFE liners in medical devices due to three core, validated properties: exceptional chemical inertness, high-temperature stability, and an extremely low coefficient of friction. These characteristics are not just theoretical; they directly address the fundamental requirements of safety, precision, and reliability in sterile medical environments.

The core reason PTFE is trusted in medicine is that its unique molecular structure creates a scientifically proven, ultra-slick, and non-reactive surface. This enhances device performance while minimizing the risk of contamination and adverse reactions within the human body.

The Scientific Foundation for PTFE in Medical Applications

The selection of any material for a medical device requires rigorous justification. Scientific validation of Polytetrafluoroethylene (PTFE) centers on how its inherent properties solve critical challenges in healthcare, from invasive surgery to diagnostic testing.

Unmatched Chemical Inertness and Purity

Research confirms that PTFE is resistant to nearly all industrial chemicals and solvents. This chemical inertness is paramount in medical applications.

It ensures that the liner will not degrade or leach substances when exposed to bodily fluids, drugs, or aggressive cleaning agents. This purity helps prevent contamination and ensures the material is biocompatible.

Furthermore, its non-porous and non-stick surface resists bacterial adhesion, which is critical for devices like catheters used in sensitive procedures where infection control is non-negotiable.

Exceptional Thermal Stability

PTFE exhibits remarkable stability across a wide range of temperatures. This property is essential for medical devices that must undergo repeated sterilization cycles.

Whether through autoclaving (steam and high pressure) or other heat-based methods, PTFE liners maintain their structural integrity and performance characteristics. This ensures the device remains safe and effective throughout its intended lifespan.

Extremely Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any known solid material, a property often referred to as lubricity. This is not just an incidental benefit; it is a primary reason for its use.

In catheters and endoscopes, this slick surface reduces friction against body tissue, minimizing patient trauma during insertion and removal. In components like syringe plungers or pump seals, it ensures smooth, precise, and reliable mechanical movement without the need for external lubricants.

Proven Durability and Longevity

Scientific studies also highlight PTFE's resistance to wear, environmental stress, and chemical degradation. This durability is a key factor in device reliability.

By extending the operational lifespan of a device, PTFE liners reduce the frequency of replacement. This contributes to greater cost-efficiency and, more importantly, consistent performance in critical healthcare settings.

Understanding the Trade-offs and Considerations

While PTFE's scientific advantages are clear, an objective analysis requires acknowledging its limitations. No material is a universal solution, and proper application is key.

Not a Structural Material

PTFE is a relatively soft material. While it has excellent properties as a liner or coating, it is generally not suitable for load-bearing or high-strength structural components on its own. Its value lies in enhancing the surface of a more rigid underlying material.

Sterilization Method Compatibility

Although PTFE has excellent thermal stability for autoclaving, certain sterilization methods can be a concern. Prolonged exposure to high-energy radiation, such as gamma sterilization, can cause the PTFE polymer chains to break down over time, potentially compromising its properties. This must be considered during the device design phase.

Manufacturing and Processing

Fabricating PTFE components and applying them as liners can be more complex and costly than working with common commodity plastics. The material's unique properties require specialized processing techniques to achieve a final, functional part.

Making the Right Choice for Your Goal

Your specific application will determine which of PTFE's scientifically validated properties is most critical.

- If your primary focus is preventing contamination and ensuring biocompatibility: The validated chemical inertness and purity of medical-grade PTFE are your most important justifications.

- If your primary focus is smooth mechanical action and patient comfort: The extremely low coefficient of friction is the key scientific property to emphasize for devices like catheters, guidewires, or plungers.

- If your primary focus is device reliability after repeated use: The material's proven thermal stability for sterilization and its resistance to chemical degradation provide the strongest support.

By aligning PTFE's scientifically proven characteristics with your specific design needs, you can make a confident and well-justified material choice.

Summary Table:

| Scientific Property | Key Benefit for Medical Devices |

|---|---|

| Chemical Inertness | Biocompatibility; resists bodily fluids, drugs, and cleaning agents. |

| Thermal Stability | Withstands repeated autoclaving and sterilization cycles. |

| Low Coefficient of Friction | Reduces tissue trauma in catheters; ensures smooth mechanical action. |

| Durability & Longevity | Maintains performance, reducing replacement frequency and cost. |

Leverage Scientifically Validated PTFE for Your Medical Device

The research is clear: PTFE's properties are essential for safety, precision, and reliability in medical applications. KINTEK specializes in manufacturing high-purity, medical-grade PTFE components—including custom liners, seals, and labware—for the semiconductor, medical, and laboratory industries.

We combine precision production with extensive material expertise to help you:

- Enhance Device Biocompatibility: Ensure patient safety with chemically inert liners.

- Achieve Smooth Mechanical Function: Leverage PTFE's low friction for catheters, plungers, and seals.

- Guarantee Sterilization Compatibility: Design devices that withstand repeated autoclaving.

From prototypes to high-volume orders, we provide custom fabrication to meet your exact specifications. Contact KINTEPT today to discuss how our PTFE solutions can elevate your medical device's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments