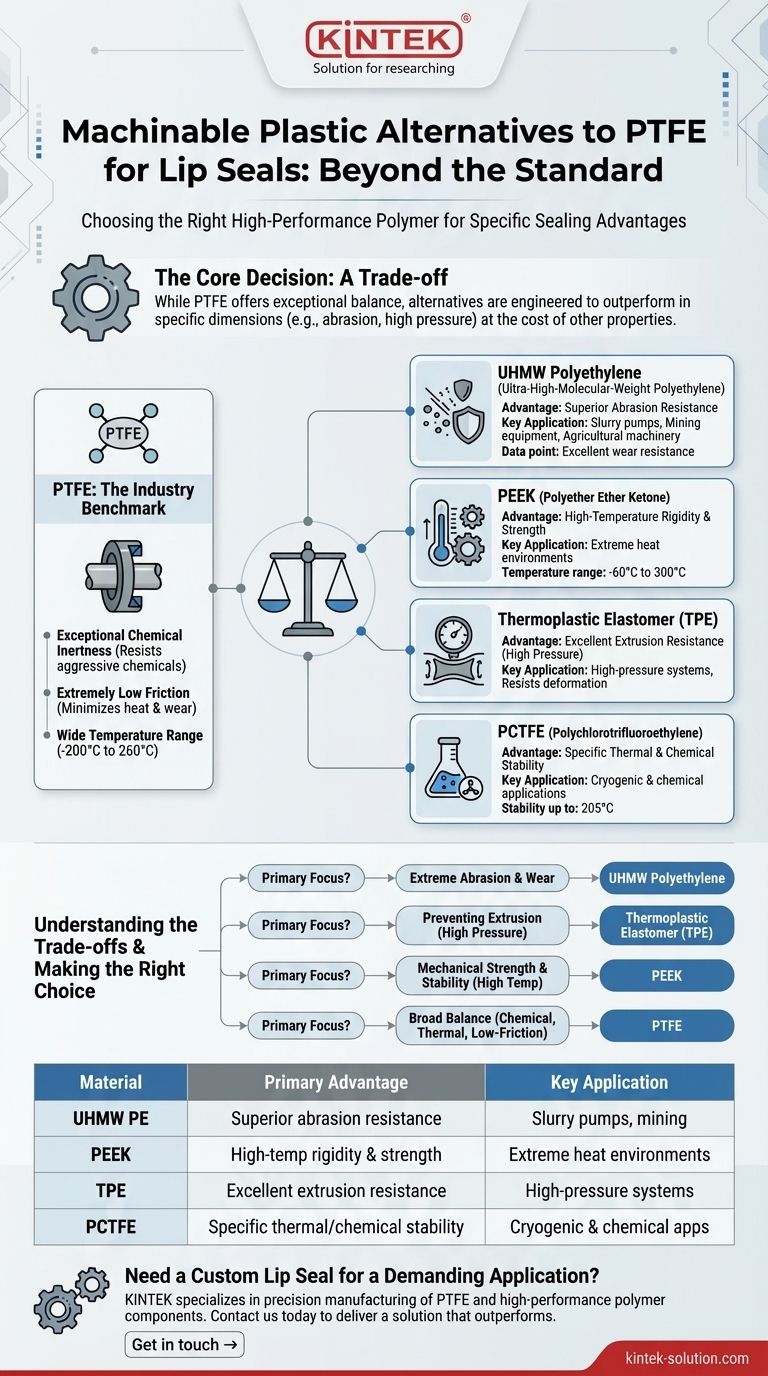

While PTFE is a dominant material, several other high-performance machinable plastics are used for lip seals, each chosen for a specific advantage. The primary alternatives include UHMW Polyethylene for superior abrasion resistance, PEEK for high-temperature rigidity, Thermoplastic Elastomer for extrusion resistance, and PCTFE for its specific thermal stability. Selecting the right material requires matching its unique properties to the precise demands of the sealing application.

The core decision is a trade-off. While PTFE offers an exceptional all-around balance of chemical inertness, low friction, and a vast temperature range, alternative polymers are engineered to outperform it in one specific dimension, such as abrasion resistance or high-pressure stability.

Why PTFE is the Industry Standard

To understand the alternatives, we must first establish the benchmark. Polytetrafluoroethylene (PTFE) is not the default choice by accident; its inherent properties make it a uniquely versatile sealing material.

Exceptional Chemical Inertness

PTFE is virtually immune to attack from almost all industrial chemicals, including aggressive solvents, acids, and bases. This makes it a safe and reliable choice for applications in chemical processing, pharmaceuticals, and manufacturing.

Extremely Low Friction

One of PTFE's most famous properties is its incredibly low coefficient of friction. This "slipperiness" minimizes heat generation and wear on both the seal and the rotating shaft, extending the operational life of the entire assembly.

Wide Temperature Range

PTFE performs reliably across an exceptionally broad thermal spectrum, from cryogenic lows of -200°C up to continuous service at 260°C (-328°F to 500°F). This allows it to function in extreme environments where other elastomers and plastics would become brittle or degrade.

Key Alternatives and Their Specific Advantages

When an application's demands exceed PTFE's capabilities in a specific area, engineers turn to other machinable plastics.

UHMW Polyethylene (For High Abrasion)

Ultra-High-Molecular-Weight Polyethylene is the go-to material when wear and abrasion are the primary modes of failure. It offers outstanding resistance to abrasive media, making it ideal for seals in slurry pumps, mining equipment, or agricultural machinery.

PEEK (For Rigidity and Extreme Heat)

Polyether Ether Ketone is a high-performance thermoplastic known for its remarkable mechanical strength and rigidity, especially at high temperatures. It maintains its properties in a range from -60°C up to 300°C (-76°F to 572°F) and is also highly chemically inert.

Thermoplastic Elastomer (TPE) (For High Pressure)

TPEs bridge the gap between plastics and rubbers. For sealing, their key benefit is excellent extrusion resistance. In high-pressure applications, softer materials can be forced into the clearance gaps, leading to failure. TPEs resist this deformation, ensuring seal integrity.

PCTFE (For Specific Thermal and Chemical Stability)

Polychlorotrifluoroethylene offers a unique combination of properties, including excellent chemical resistance and stability up to 205°C (401°F). It is often used in cryogenic and chemical applications where a rigid, stable fluoropolymer is required.

Understanding the Trade-offs

Selecting an alternative material is never without compromises. The goal is to choose the material whose strengths are most relevant and whose weaknesses are least detrimental to your specific application.

Cost vs. Performance

High-performance polymers like PEEK and PCTFE typically carry a significantly higher material cost than PTFE or UHMW Polyethylene. This cost must be justified by a clear performance requirement that standard materials cannot meet.

Specialization Over Versatility

While PEEK excels at high temperatures, it does not match PTFE's performance in cryogenic conditions. Similarly, while UHMW has superior abrasion resistance, it generally has a higher coefficient of friction than PTFE. You are often trading PTFE's broad versatility for specialized excellence.

Machinability and Design

Each plastic has unique machining characteristics. The design of the seal and the manufacturing process may need to be adjusted to accommodate the specific properties of materials like the highly rigid PEEK or the more flexible TPEs.

Making the Right Choice for Your Application

Your final selection should be driven entirely by the operational environment and the primary cause of seal failure.

- If your primary focus is extreme abrasion and wear: UHMW Polyethylene is the most logical choice.

- If your primary focus is preventing seal extrusion under high pressure: A Thermoplastic Elastomer will provide the necessary resilience.

- If your primary focus is mechanical strength and stability at very high temperatures: PEEK is the premier material for the job.

- If your primary focus is a broad balance of chemical, thermal, and low-friction performance: PTFE and its various filled composites remain the industry benchmark.

Ultimately, choosing the correct seal material is about precisely matching the polymer's strengths to the specific challenges of your application.

Summary Table:

| Material | Primary Advantage | Key Application |

|---|---|---|

| UHMW Polyethylene | Superior abrasion resistance | Slurry pumps, mining equipment |

| PEEK | High-temperature rigidity & strength | Extreme heat environments |

| Thermoplastic Elastomer (TPE) | Excellent extrusion resistance | High-pressure systems |

| PCTFE | Specific thermal & chemical stability | Cryogenic & chemical applications |

Need a Custom Lip Seal for a Demanding Application?

Choosing the right machinable plastic is critical for seal performance and longevity. The experts at KINTEK specialize in precision manufacturing of PTFE and high-performance polymer components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We provide custom fabrication from prototypes to high-volume orders, ensuring your lip seals are perfectly matched to your application's unique challenges.

Contact us today to discuss your requirements and let our material science expertise deliver a solution that outperforms. Get in touch →

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the benefits of using PTFE seals? Unmatched Chemical & Temperature Resistance

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- What is the overall operating temperature range for PTFE seals, gaskets, and O-rings? Achieve Sealing Integrity from -200°C to +260°C