In industrial environments, the choice of a sealing material is a critical decision that directly impacts safety, reliability, and cost. The chemical resistance of Polytetrafluoroethylene (PTFE) gaskets provides a profound benefit by creating a nearly universal seal that withstands exposure to a vast range of aggressive chemicals, including acids, alkalis, and solvents. This inherent stability prevents material degradation, ensuring a reliable, long-lasting seal in the most demanding applications.

The true value of PTFE's chemical resistance isn't merely its ability to survive harsh chemicals; it's the operational certainty it delivers. By eliminating material degradation as a primary point of failure, industries can dramatically reduce costly downtime, minimize safety risks, and ensure long-term system integrity.

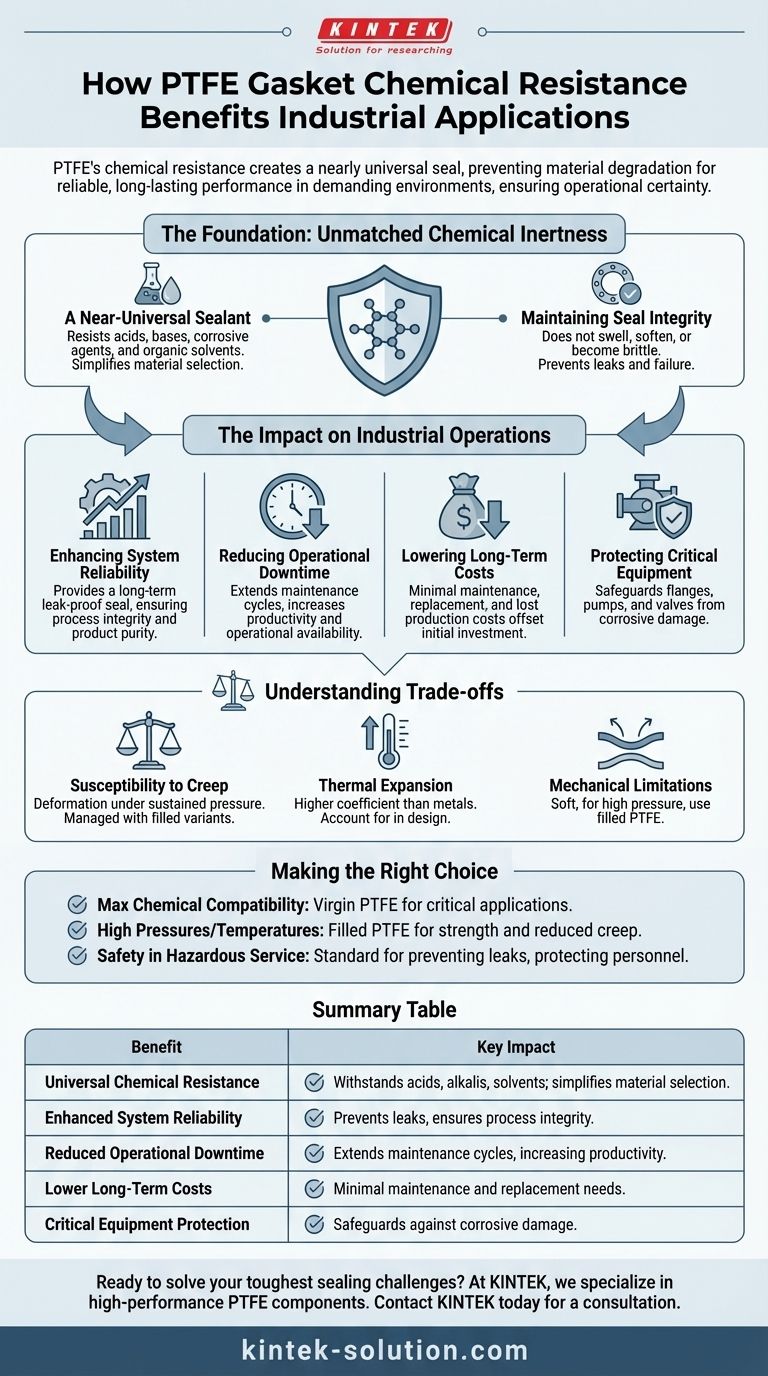

The Foundation: Unmatched Chemical Inertness

The core benefit of PTFE stems from its unique molecular structure, which renders it almost completely inert. This property is the reason it is a default choice for handling corrosive and hazardous materials.

A Near-Universal Sealant

PTFE is resistant to virtually all industrial chemicals. This includes strong acids, bases, corrosive agents, and organic solvents that would quickly degrade most other sealing materials.

This broad-spectrum resistance simplifies material selection, as a single gasket type can often be specified for a wide variety of services within a facility.

Maintaining Seal Integrity

Chemical resistance means the gasket does not swell, soften, or become brittle when exposed to process fluids. It maintains its physical shape and mechanical properties.

This stability is crucial for preventing leaks, as any change in the gasket's form could compromise the integrity of the seal, leading to fugitive emissions or catastrophic failure.

The Impact on Industrial Operations

The chemical inertness of PTFE translates directly into tangible operational and financial advantages. It moves the gasket from a simple component to a strategic asset for reliability.

Enhancing System Reliability

By resisting chemical attack, PTFE gaskets provide a tight, leak-proof seal that endures for the long term. This consistency is vital in industries like pharmaceuticals, chemical manufacturing, and oil and gas.

Reliable sealing ensures that processes run as designed, protecting product purity and system efficiency.

Reducing Operational Downtime

Gasket failure is a common cause of unscheduled shutdowns for maintenance and repair. The durability of PTFE in harsh environments significantly extends the time between maintenance cycles.

Fewer shutdowns mean greater productivity and higher operational availability of critical equipment.

Lowering Long-Term Costs

While PTFE may have a higher initial cost than some alternatives, its long service life and reliability lead to a lower total cost of ownership.

This is achieved by minimizing the costs associated with maintenance labor, replacement parts, and lost production during downtime.

Protecting Critical Equipment

A failed gasket doesn't just leak; it can allow corrosive chemicals to damage expensive flanges, pumps, and valves.

Using a chemically resistant PTFE gasket acts as a safeguard, protecting the entire system from the degradation that a breach would cause.

Understanding the Trade-offs

While its chemical resistance is nearly absolute, PTFE is not without limitations. Acknowledging these trade-offs is key to proper application and engineering.

Susceptibility to Creep

Virgin PTFE can be susceptible to "creep" or "cold flow," where the material slowly deforms under sustained pressure, potentially loosening the seal over time. This is often managed by using filled PTFE variants.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than the metals it typically seals against. This must be accounted for in system design, especially in applications with wide temperature fluctuations.

Mechanical Limitations

Compared to metals or harder plastics, virgin PTFE is a relatively soft material. For high-pressure applications, filled PTFE gaskets (which include glass, carbon, or other agents) are used to improve mechanical strength and rigidity.

Making the Right Choice for Your Application

Selecting the right gasket requires balancing chemical compatibility with the mechanical and thermal demands of your system.

- If your primary focus is maximum chemical compatibility: Pure, virgin PTFE offers the broadest resistance for the most critical applications in pharmaceuticals or semiconductor manufacturing.

- If your primary focus is managing high pressures or temperatures: Consider a filled PTFE gasket, which incorporates materials like glass or carbon to improve mechanical strength and reduce creep.

- If your primary focus is safety in hazardous service: PTFE's proven reliability makes it the standard for preventing leaks of dangerous materials, protecting personnel and the environment.

Ultimately, leveraging PTFE's chemical resistance is a strategic decision to build a more resilient, safe, and predictable industrial process.

Summary Table:

| Benefit | Key Impact |

|---|---|

| Universal Chemical Resistance | Withstands acids, alkalis, solvents; simplifies material selection. |

| Enhanced System Reliability | Prevents leaks, ensures process integrity, and protects product purity. |

| Reduced Operational Downtime | Extends maintenance cycles, increasing productivity and availability. |

| Lower Long-Term Costs | Higher initial cost offset by minimal maintenance and replacement needs. |

| Critical Equipment Protection | Safeguards flanges, pumps, and valves from corrosive damage. |

Ready to solve your toughest sealing challenges?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including precision gaskets, seals, and liners. Our expertise ensures you get a sealing solution that delivers the chemical resistance and reliability your application demands, whether you're in the semiconductor, medical, laboratory, or industrial sector.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision to enhance your operational safety and efficiency.

Contact KINTEK today for a consultation and let our experts help you build a more resilient process.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications