The fundamental reason PTFE fasteners excel in high-temperature environments is the material's outstanding thermal stability. Polytetrafluoroethylene (PTFE) is engineered to maintain its structural and dimensional integrity across an extreme temperature range, from cryogenic lows to high-heat applications, without degrading like many traditional polymers or coatings.

While many materials weaken or fail under thermal stress, PTFE's unique molecular structure allows it to resist degradation from extreme heat. This makes it an essential material for applications demanding a combination of thermal stability, chemical inertness, and low friction.

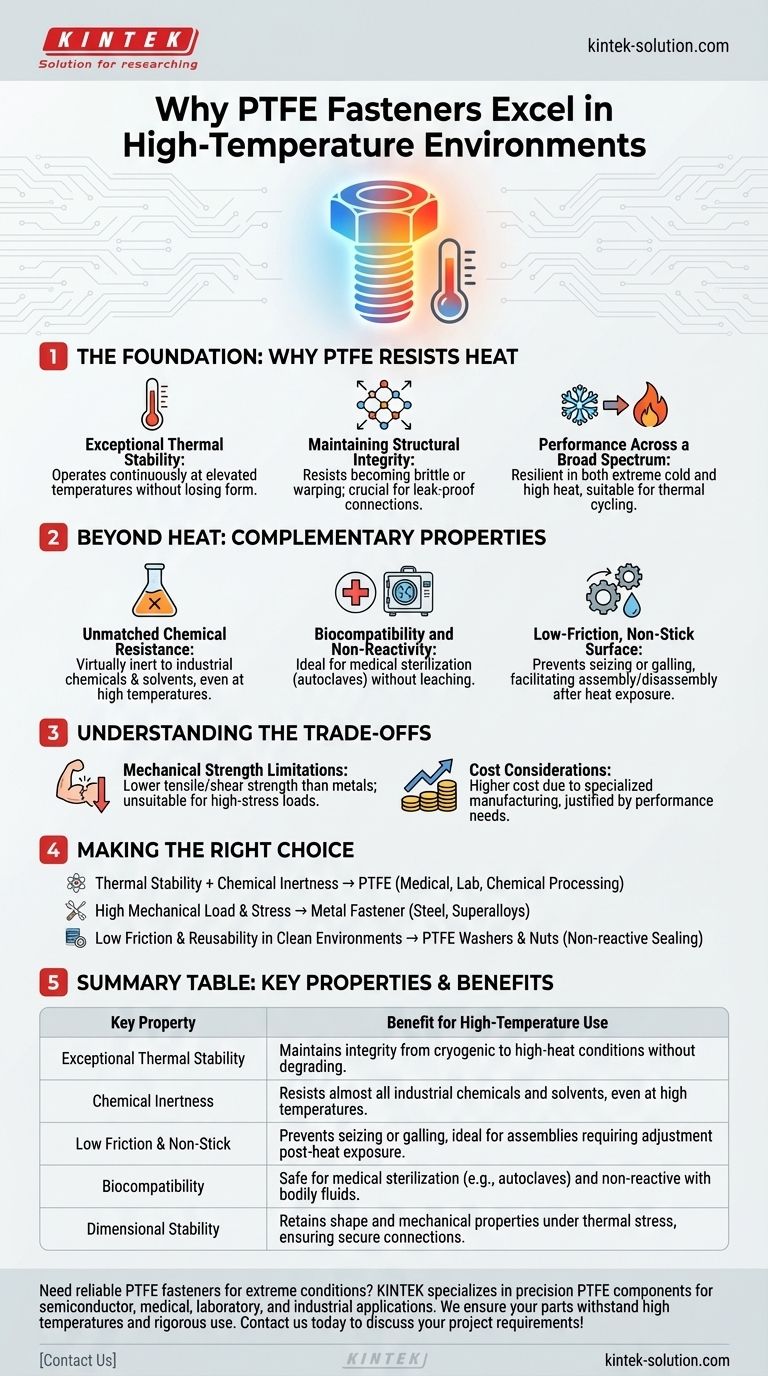

The Foundation: Why PTFE Resists Heat

At its core, PTFE's suitability for high temperatures is not a single feature but a result of its inherent material properties. Understanding these characteristics is key to deploying it effectively.

Exceptional Thermal Stability

PTFE possesses a very high melting point and can operate continuously at elevated temperatures where other materials would begin to lose their form and function. This ensures reliable performance under constant thermal stress.

Maintaining Structural Integrity

Unlike materials that can become brittle or warp, PTFE fasteners maintain their shape and mechanical properties. This dimensional stability is crucial for ensuring connections remain secure and leak-proof, even with frequent temperature fluctuations.

Performance Across a Broad Spectrum

The material's resilience is not limited to heat. PTFE also performs exceptionally well in extremely cold conditions, making it a versatile choice for applications that cycle between temperature extremes.

Beyond Heat: Complementary Properties for Demanding Environments

High-temperature environments are often accompanied by other harsh conditions. PTFE's value is amplified by a set of secondary properties that make it a robust solution for complex challenges.

Unmatched Chemical Resistance

PTFE is virtually inert and resistant to almost all industrial chemicals and solvents. This makes it ideal for applications where high temperatures and aggressive chemical agents are present simultaneously, such as in chemical processing or medical sterilization.

Biocompatibility and Non-Reactivity

In the medical field, devices must often undergo high-temperature sterilization. PTFE fasteners are perfect for this role because they do not react with bodily fluids or cleaning agents and can withstand the heat of an autoclave without leaching or degrading.

Low-Friction, Non-Stick Surface

PTFE's famously low coefficient of friction ensures that threaded connections do not seize or gall, even without lubrication. This is particularly valuable in assemblies that may need to be adjusted or disassembled after exposure to high heat.

Understanding the Trade-offs

No material is a universal solution. Being a trusted advisor means acknowledging where a material may not be the best fit. Objectivity requires understanding the limitations of PTFE.

Mechanical Strength Limitations

PTFE is a polymer, not a metal. Its tensile and shear strength are significantly lower than steel, titanium, or other metal alloys. This makes PTFE fasteners unsuitable for high-stress or heavy load-bearing structural applications.

Cost Considerations

The specialized manufacturing process and raw material costs make PTFE fasteners more expensive than those made from conventional materials like stainless steel or nylon. Their use is typically justified by performance requirements that other materials cannot meet.

Making the Right Choice for Your Application

Selecting the correct fastener material requires balancing performance needs with physical limitations and cost. Your primary goal should dictate your choice.

- If your primary focus is thermal stability combined with chemical inertness: PTFE is an ideal choice for medical devices, laboratory equipment, and chemical processing machinery.

- If your primary focus is high mechanical load and stress: A metal fastener made from an appropriate steel alloy or superalloy is the correct engineering choice.

- If your primary focus is low friction and reusability in a clean environment: PTFE washers and nuts provide excellent, non-reactive sealing and load distribution.

Ultimately, choosing PTFE fasteners is a decision for specialized environments where their unique combination of thermal, chemical, and physical properties is a critical requirement.

Summary Table:

| Key Property | Benefit for High-Temperature Use |

|---|---|

| Exceptional Thermal Stability | Maintains integrity from cryogenic to high-heat conditions without degrading. |

| Chemical Inertness | Resists almost all industrial chemicals and solvents, even at high temperatures. |

| Low Friction & Non-Stick | Prevents seizing or galling, ideal for assemblies requiring adjustment post-heat exposure. |

| Biocompatibility | Safe for medical sterilization (e.g., autoclaves) and non-reactive with bodily fluids. |

| Dimensional Stability | Retains shape and mechanical properties under thermal stress, ensuring secure connections. |

Need reliable PTFE fasteners for extreme conditions? KINTEK specializes in precision PTFE components (seals, liners, labware, and custom fasteners) for semiconductor, medical, laboratory, and industrial applications. We ensure your parts withstand high temperatures, chemical exposure, and rigorous use—from prototypes to high-volume orders. Contact us today to discuss your project requirements and leverage our expertise in custom fabrication!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions