In short, the key factors contributing to long-term savings with Teflon gland packing are a significant reduction in replacement frequency, lower associated maintenance costs, and minimized operational downtime. While the initial purchase price is often higher than alternatives, its superior durability and performance create a compelling return on investment over the equipment's lifecycle.

The central takeaway is that viewing Teflon gland packing as a strategic investment rather than a simple expense is crucial. Its higher upfront cost is consistently offset by superior reliability, which translates directly into fewer shutdowns, less labor, and reduced wear on critical equipment.

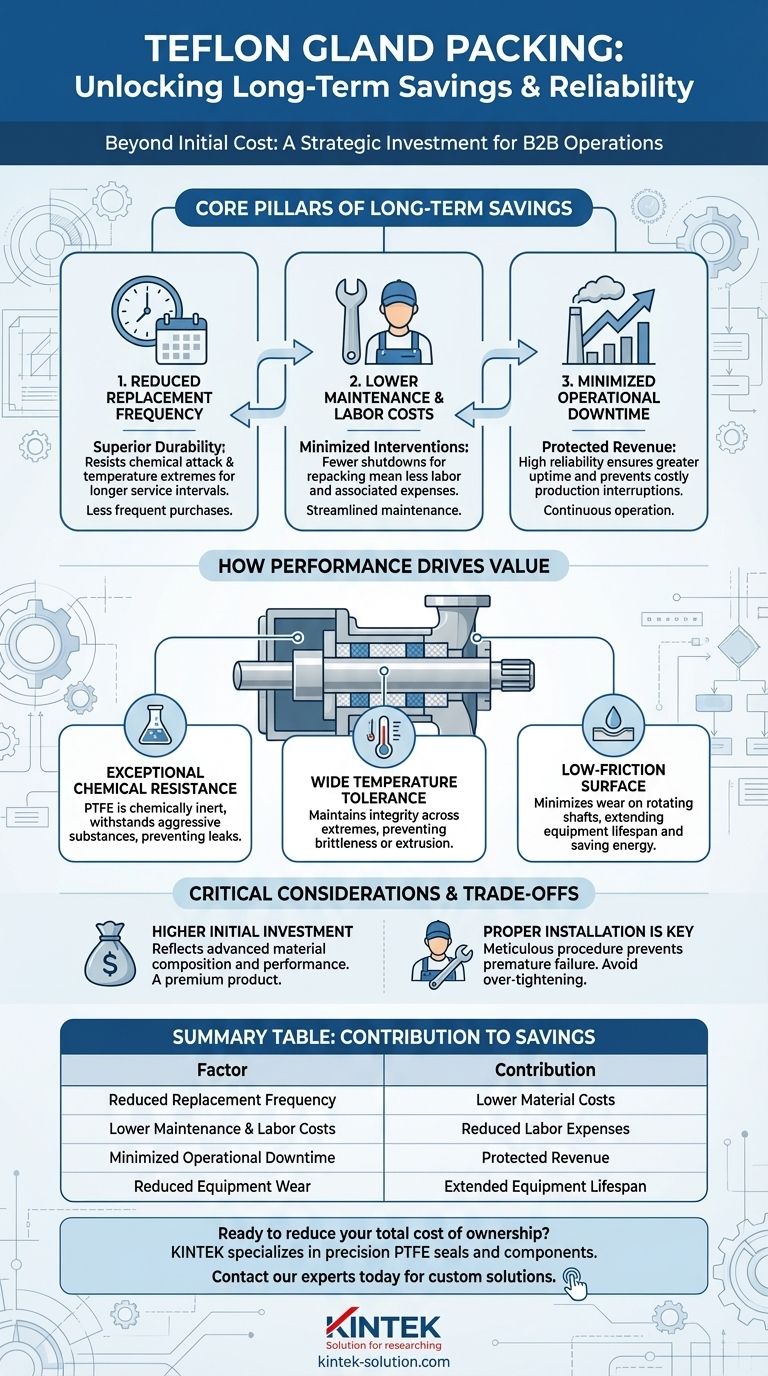

The Core Pillars of Long-Term Savings

The financial benefits of Teflon gland packing are not realized at the point of purchase, but rather through sustained, reliable operation. The savings are rooted in three interconnected factors that reduce the total cost of ownership.

Reduced Replacement Frequency

Teflon (PTFE) packing is engineered for longevity. Its inherent resistance to chemical attack and temperature extremes means it degrades far more slowly than many conventional packing materials, leading to significantly longer service intervals.

Lower Maintenance and Labor Costs

Fewer replacements directly translate to lower labor costs. Each time a pump or valve must be repacked, it requires shutting down the line, disassembling the gland, removing old material, installing new rings, and reassembly—a labor-intensive process that is minimized with a more durable solution.

Minimized Operational Downtime

For most industrial operations, downtime is the single most significant cost. A failed packing can bring a critical process to a halt. The reliability of Teflon packing ensures greater uptime, protecting revenue-generating activities and preventing costly production interruptions.

How Performance Characteristics Drive Value

The financial benefits are a direct result of Teflon's unique material properties. Understanding these characteristics clarifies why it excels in demanding environments.

Exceptional Chemical Resistance

PTFE is one of the most chemically inert materials available. It can withstand a vast range of aggressive chemicals, acids, and caustics without degrading, preventing leaks and premature failure in chemical processing and other harsh applications.

Wide Temperature Tolerance

Teflon packing maintains its integrity and sealing capability across a broad spectrum of temperatures. This stability prevents the material from becoming brittle in cold conditions or extruding under high heat, ensuring a reliable seal.

Low-Friction Surface

The material's exceptionally low coefficient of friction is a critical advantage. It reduces the energy required to operate pumps and valves and, more importantly, minimizes wear on the rotating shaft or stem. This extends the life of the equipment itself, not just the packing.

Understanding the Trade-offs and Considerations

To make an informed decision, it is essential to weigh the benefits against the initial investment and procedural requirements. Objectivity is key to leveraging Teflon packing effectively.

Higher Initial Investment

The most apparent trade-off is the upfront cost. Teflon gland packing is a premium product, and its initial purchase price reflects its advanced material composition and performance capabilities.

The Critical Role of Correct Installation

The performance benefits of Teflon packing can be completely negated by improper installation. Common mistakes like over-tightening the gland follower can prevent necessary lubrication and cause premature failure of both the packing and the shaft.

Ensuring Proper Procedure

Optimal performance demands meticulous installation. This includes thoroughly cleaning the stuffing box, precisely cutting the packing rings to size, and tightening the gland follower evenly and sequentially to achieve a proper seal without over-compression.

Safety and Environmental Protocols

While the end product is inert and safe for applications like food and pharmaceuticals, PTFE does not biodegrade and requires proper disposal. Technicians should use appropriate PPE to avoid inhaling dust during removal and installation.

Making the Right Choice for Your Goal

Selecting the right sealing solution depends entirely on your operational priorities. By analyzing your primary goals, you can determine if Teflon gland packing is the most effective choice.

- If your primary focus is maximizing uptime: The superior reliability and extended service life of Teflon packing make it the ideal choice for minimizing unscheduled shutdowns in critical processes.

- If your primary focus is handling aggressive chemicals: The exceptional chemical inertness of PTFE provides a level of security and longevity that few other materials can match.

- If your primary focus is minimizing total lifecycle cost: Looking beyond the initial price reveals that reduced maintenance, lower labor costs, and less equipment wear make Teflon a highly economical choice over time.

Ultimately, choosing Teflon gland packing is a strategic decision to invest in the long-term reliability and efficiency of your operation.

Summary Table:

| Factor | Contribution to Long-Term Savings |

|---|---|

| Reduced Replacement Frequency | Superior chemical/thermal resistance extends service life, lowering material costs. |

| Lower Maintenance & Labor Costs | Fewer shutdowns for repacking significantly reduce labor hours and associated expenses. |

| Minimized Operational Downtime | Enhanced reliability prevents costly production interruptions, protecting revenue. |

| Reduced Equipment Wear | Low-friction surface minimizes wear on shafts/stems, extending equipment lifespan. |

Ready to reduce your total cost of ownership with high-performance PTFE components?

KINTEK specializes in manufacturing precision PTFE seals, gland packing, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a solution that delivers superior reliability, minimizes downtime, and protects your critical equipment.

Contact our experts today to discuss your specific application and receive a custom solution tailored to maximize your long-term savings.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- Which acid is not resistant to Teflon encapsulated O-rings? Avoid HF for Seal Integrity

- How are PTFE gaskets used in the petroleum and chemical industry? Ensure Leak-Proof Sealing in Harsh Environments

- What types of chemical substances can PTFE bushings withstand? Ensure Reliability in Aggressive Environments

- What are the key benefits of Teflon bushes for industrial applications? Reduce Friction and Maintenance

- How is non-stick cookware coated with PTFE? The Science of a Slippery Surface

- What are the disadvantages of PTFE gaskets? Key Limitations to Consider

- What makes Teflon bushes durable in industrial applications? Unlock Superior Performance with PTFE

- Can machined PTFE parts be customized? Achieve Precision Solutions for Demanding Applications