The primary acid to avoid when using Teflon encapsulated O-rings is hydrofluoric acid (HF). This specific chemical, particularly in concentrated solutions, is known to attack the fluoropolymer jacket, leading to seal degradation and failure where most other acids would have no effect.

While Teflon encapsulated O-rings provide exceptional resistance to a vast range of aggressive chemicals, their one significant vulnerability among common acids is hydrofluoric acid. Recognizing this specific limitation is critical for ensuring seal integrity and safety in demanding applications.

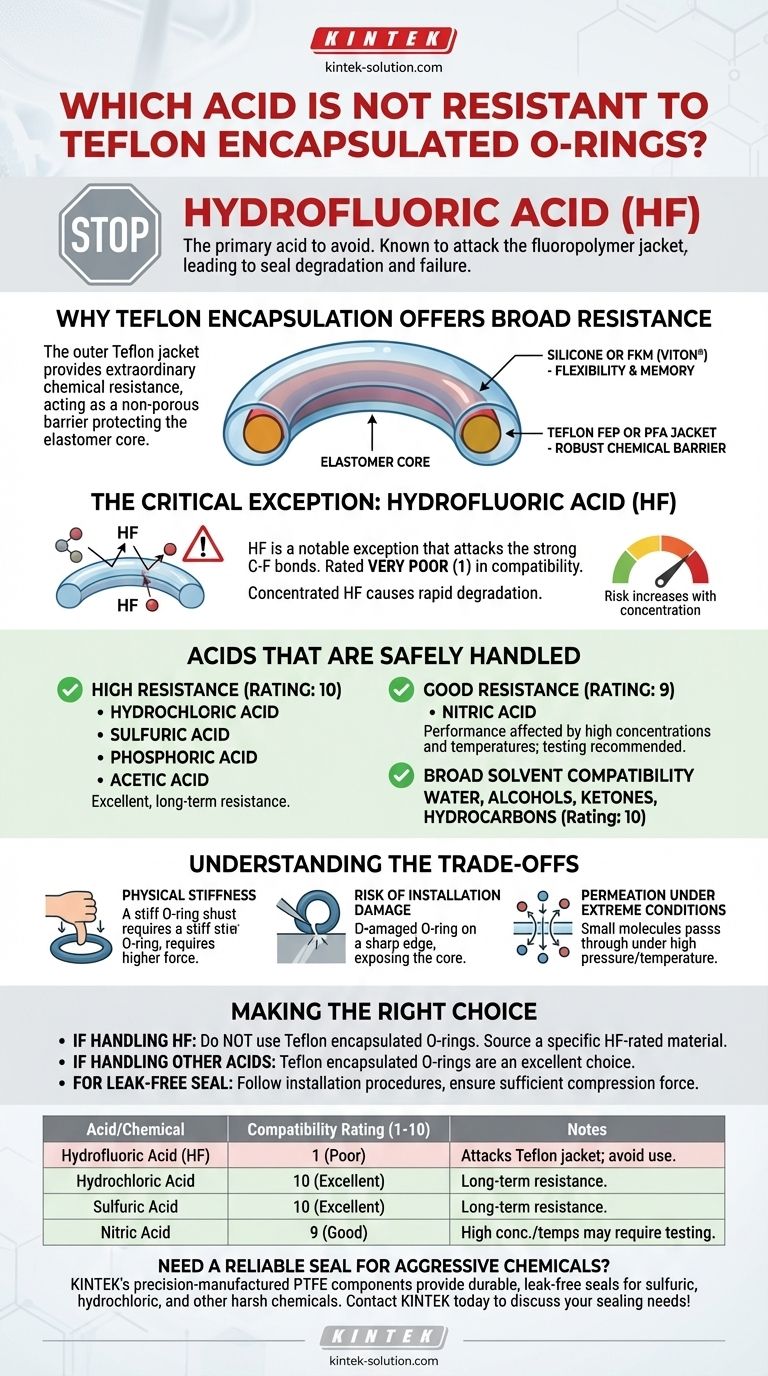

Why Teflon Encapsulation Offers Broad Resistance

The Dual-Material Structure

Teflon encapsulated O-rings are composite seals. They consist of an inner elastomeric core, typically silicone or FKM (Viton®), which provides the flexibility and "memory" needed for a proper seal.

This core is then completely enclosed in a seamless jacket made of a fluoropolymer resin, either Teflon FEP (Fluorinated Ethylene Propylene) or PFA (Perfluoroalkoxy).

The Role of the Teflon Jacket

The outer Teflon jacket is the component that provides the seal's extraordinary chemical resistance. It acts as a robust, non-porous barrier, protecting the more vulnerable elastomer core from chemical attack.

This inertness is why these seals can handle a wide array of aggressive substances without swelling, hardening, or degrading.

The Critical Exception: Hydrofluoric Acid

A Specific Chemical Vulnerability

Despite Teflon's legendary chemical resistance, hydrofluoric acid (HF) is a notable exception. It is one of the few common chemicals that can attack the strong carbon-fluorine bonds that make up the polymer's structure.

The resistance of Teflon encapsulated O-rings to HF is rated as very poor, receiving a score of 1 in compatibility charts.

The Impact of Concentration

The risk of failure increases significantly with higher concentrations of hydrofluoric acid. While very dilute solutions might have a lesser effect over short periods, concentrated HF will cause rapid degradation of the seal's protective jacket.

Acids That Are Safely Handled

High Resistance (Rating: 10)

Teflon encapsulated O-rings demonstrate excellent, long-term resistance to a wide range of common industrial acids. These include:

- Hydrochloric Acid

- Sulfuric Acid

- Phosphoric Acid

- Acetic Acid

Good Resistance with Caveats (Rating: 9)

Nitric Acid is also generally compatible. However, performance can be affected by very high concentrations and elevated temperatures, which may warrant specific testing for the application.

Broad Solvent Compatibility

Beyond acids, these seals also have a top rating (10) for resistance to most solvents, including water, alcohols (methanol, ethanol), ketones (acetone), and hydrocarbons (hexane, toluene).

Understanding the Trade-offs

Physical Stiffness vs. Chemical Resistance

The primary trade-off is not chemical but physical. The Teflon jacket makes the O-ring significantly stiffer than a standard elastomer O-ring. This may require higher compression forces to achieve a proper seal.

Risk of Installation Damage

The Teflon jacket, while durable, can be scratched or damaged during installation on sharp edges. Any breach in the jacket exposes the non-resistant inner core, completely negating the chemical barrier and leading to premature failure.

Permeation Under Extreme Conditions

While the jacket is seamless, it is not infinitely impermeable. Under conditions of very high pressure and temperature, extremely small molecules may eventually permeate the Teflon layer, though this is only a concern in the most demanding applications.

Making the Right Choice for Your Application

- If your primary focus is handling hydrofluoric acid (HF): Do not use Teflon encapsulated O-rings. You must source a seal from a material specifically rated for HF, such as certain specialty grades of FFKM.

- If your primary focus is handling most other common acids (sulfuric, hydrochloric, nitric, etc.): Teflon encapsulated O-rings are an excellent and highly reliable choice, offering a superior chemical barrier.

- If your primary focus is ensuring a leak-free seal: Always follow careful installation procedures to avoid damaging the Teflon jacket and confirm your equipment design provides sufficient force to compress the stiffer seal.

Ultimately, successful sealing depends on correctly matching the specific chemical agent and operating conditions to a material's known capabilities and limitations.

Summary Table:

| Acid / Chemical | Compatibility Rating (1-10) | Notes |

|---|---|---|

| Hydrofluoric Acid (HF) | 1 (Poor) | Attacks the Teflon jacket; avoid use. |

| Hydrochloric Acid | 10 (Excellent) | Long-term resistance. |

| Sulfuric Acid | 10 (Excellent) | Long-term resistance. |

| Nitric Acid | 9 (Good) | High concentrations/temperatures may require testing. |

Need a reliable seal for aggressive chemicals?

Teflon encapsulated O-rings offer exceptional resistance to most acids—except hydrofluoric acid. For applications involving sulfuric acid, hydrochloric acid, and other harsh chemicals, KINTEK's precision-manufactured PTFE components provide the durable, leak-free seal you require.

We specialize in custom fabrication for the semiconductor, medical, laboratory, and industrial sectors, from prototypes to high-volume orders.

Contact KINTEK today to discuss your specific sealing needs and ensure optimal performance and safety.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems