Yes, absolutely. Machined PTFE parts can be extensively customized to meet highly specific operational requirements. The inherent machinability of Polytetrafluoroethylene (PTFE) allows for precise fabrication of components in nearly any size or shape, from simple washers to complex, multi-faceted assemblies.

The core value of PTFE lies not just in its remarkable properties, but in the ability to precisely tailor those properties into custom-machined components that solve specific engineering challenges where off-the-shelf parts would fail.

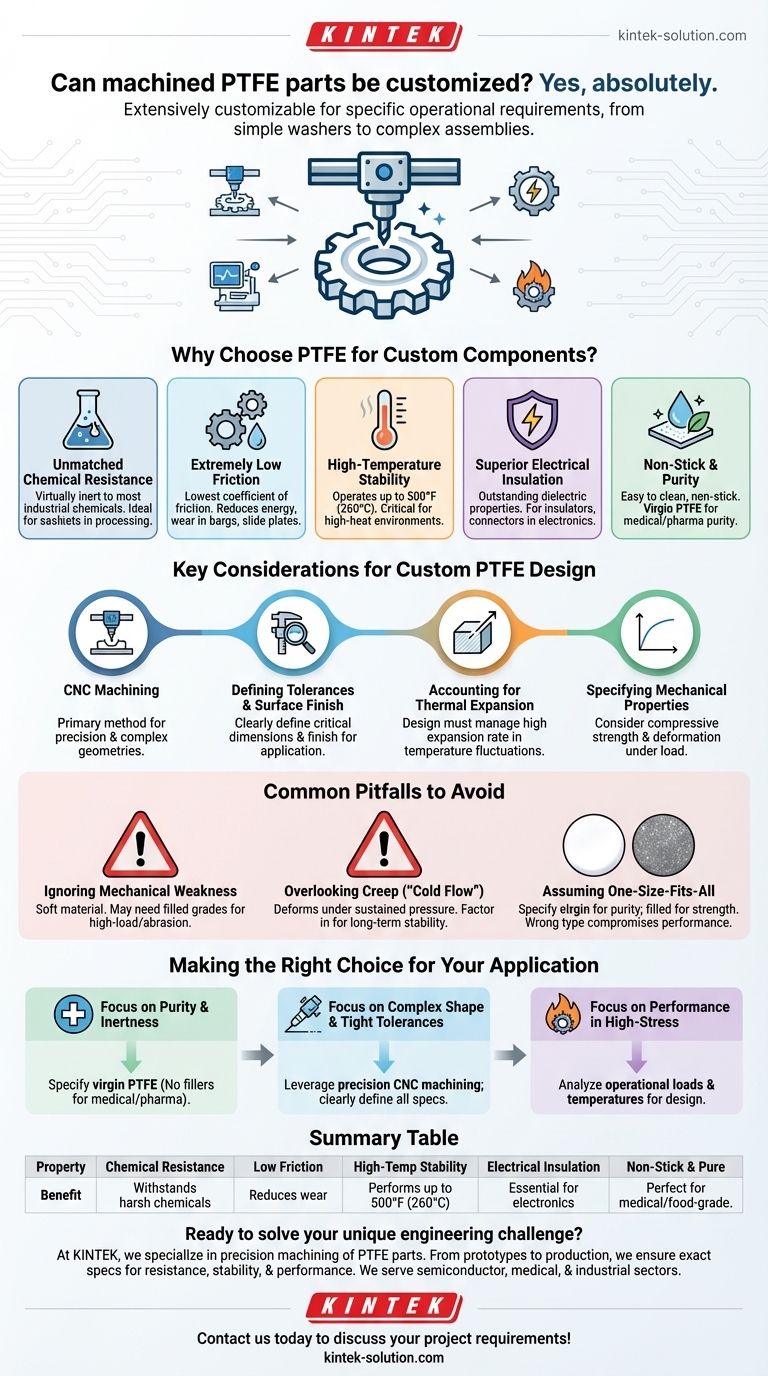

Why Choose PTFE for Custom Components?

The decision to machine a custom part from PTFE is driven by its unique combination of high-performance characteristics. These properties make it an ideal material for solving problems in demanding environments.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals. This makes it essential for custom components like tank linings, seals, and gaskets used in chemical processing, aerospace, and oil and gas industries.

Extremely Low Friction

With one of the lowest coefficients of friction of any solid material, PTFE is an excellent choice for custom bearings, slide plates, and seals. These components reduce energy consumption and wear in moving systems.

High-Temperature Stability

Custom PTFE parts can operate continuously at temperatures up to 500°F (260°C). This thermal resistance is critical for applications in high-temperature processing and industrial equipment.

Superior Electrical Insulation

PTFE has outstanding dielectric properties, making it a top choice for custom-machined insulators, connectors, and other components in the electronics and semiconductor industries.

Non-Stick and Purity

The material's non-stick surface makes it easy to clean, a vital feature for food-grade cutting boards and components in food processing. For medical and pharmaceutical uses, virgin PTFE is preferred for its purity, as it contains no fillers or additives.

Key Considerations for Custom PTFE Design

Successful customization requires more than just a shape. The design must account for the material's specific physical behaviors to ensure the final part performs as intended in its operational environment.

The Role of CNC Machining

CNC (Computer Numerical Control) machining is the primary method for creating custom PTFE parts. This technology allows for high precision and the creation of complex geometries that perfectly match design specifications.

Defining Tolerances and Surface Finish

Your operational needs will dictate the required tolerances and surface finish. A precision seal, for example, will require much tighter tolerances than a simple protective lining. These factors must be clearly defined upfront.

Accounting for Thermal Expansion

PTFE has a relatively high rate of thermal expansion. Designs for parts that will experience temperature fluctuations must account for this expansion and contraction to avoid stress and failure.

Specifying Mechanical Properties

The design must also consider the required compressive strength and other mechanical properties. The part needs to withstand the physical stresses of its specific application without deforming or failing.

Common Pitfalls to Avoid

While highly versatile, misapplication of PTFE can lead to poor outcomes. Understanding its limitations is as important as knowing its strengths.

Ignoring Mechanical Weakness

Compared to metals or other engineering plastics, PTFE is soft and has lower tensile strength and wear resistance. For high-load or high-abrasion applications, a different material or a filled grade of PTFE may be necessary.

Overlooking Creep or "Cold Flow"

Under sustained pressure, PTFE can slowly deform over time—a phenomenon known as creep. Designs for structural components or tight-tolerance seals must factor in this behavior to ensure long-term stability.

Assuming One-Size-Fits-All

Not all PTFE is the same. Using virgin PTFE is critical for high-purity applications, but filled grades (with glass, carbon, or other additives) are often used to enhance mechanical properties like stiffness and wear resistance. Specifying the wrong type can compromise performance.

Making the Right Choice for Your Application

Your specific goal will determine the key design and material considerations for your custom part.

- If your primary focus is purity and chemical inertness: Specify virgin PTFE to ensure no fillers or additives can contaminate your process, which is critical for medical or pharmaceutical uses.

- If your primary focus is a complex shape with tight tolerances: Leverage the capabilities of precision CNC machining and clearly define all critical dimensions and surface finish requirements.

- If your primary focus is performance in a high-stress environment: Carefully analyze the operational loads and temperatures to ensure the design accounts for PTFE's mechanical properties and thermal expansion.

By aligning the remarkable properties of PTFE with precise custom machining, you can engineer a component that delivers optimal performance for your unique challenge.

Summary Table:

| Property | Benefit for Custom Parts |

|---|---|

| Chemical Resistance | Withstands harsh chemicals, ideal for seals and liners |

| Low Friction | Reduces wear in bearings and moving components |

| High-Temp Stability | Performs reliably up to 500°F (260°C) |

| Electrical Insulation | Essential for semiconductor and electronic parts |

| Non-Stick & Pure | Perfect for medical, pharmaceutical, and food-grade applications |

Ready to solve your unique engineering challenge with a custom PTFE component?

At KINTEK, we specialize in precision machining of PTFE parts—from simple seals to complex, multi-faceted assemblies. Whether you need prototypes or high-volume production, our expertise ensures your components meet exact specifications for chemical resistance, thermal stability, and mechanical performance.

We serve the semiconductor, medical, laboratory, and industrial sectors with custom fabrication that leverages PTFE's superior properties. Let us help you design and manufacture the perfect part for your application.

Contact us today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability