The durability of Teflon bushes in industrial settings stems from a powerful combination of inherent chemical, thermal, and mechanical properties. Their exceptional resistance to wear, abrasion, and deformation is a direct result of an extremely low friction coefficient and profound chemical inertness, allowing them to perform reliably under high loads, constant vibration, and in harsh operating environments.

Choosing the right bushing material is a critical decision for operational reliability. Teflon's durability is not simply about physical toughness; it's about its unique ability to maintain performance integrity by simultaneously resisting chemical attack, extreme temperatures, and mechanical wear.

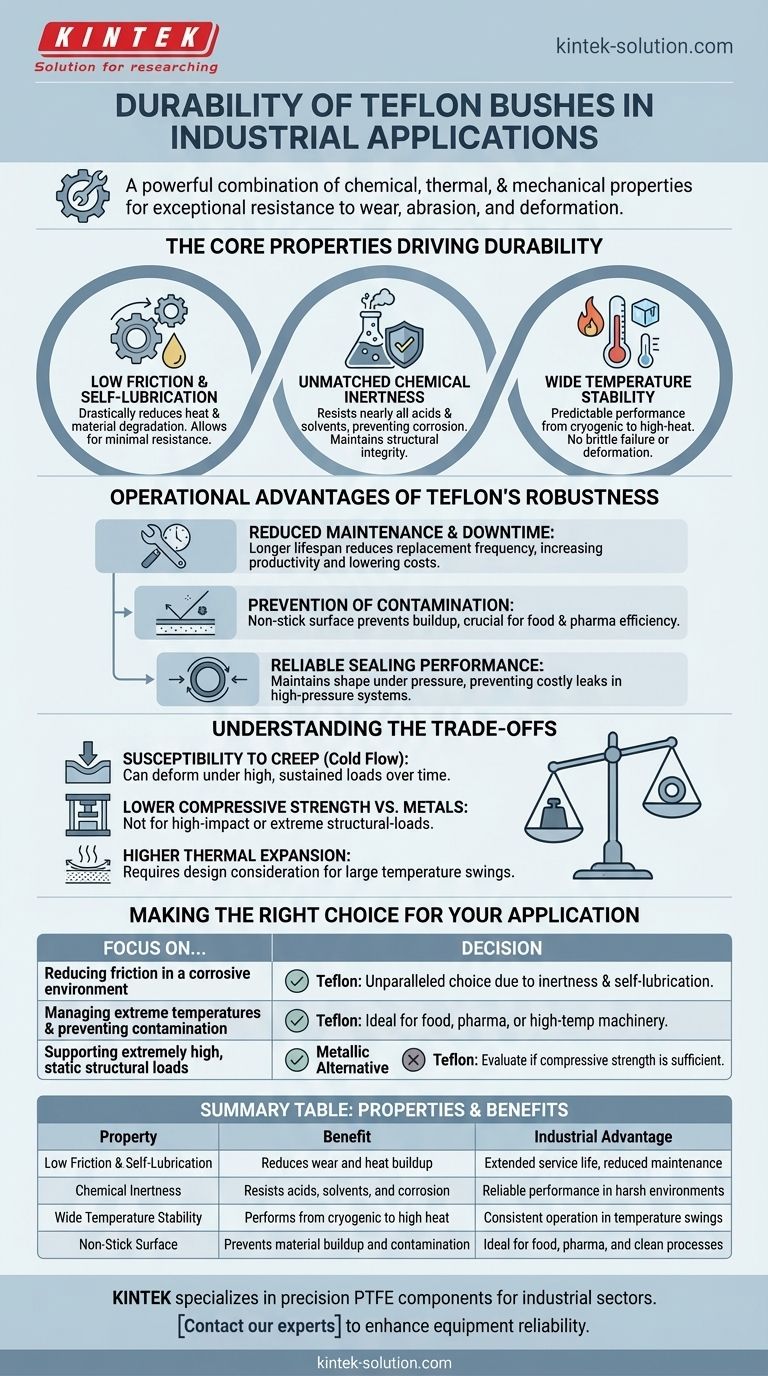

The Core Properties Driving Durability

The term "Teflon" is the brand name for Polytetrafluoroethylene (PTFE), a material whose molecular structure gives it a unique set of characteristics. These properties work in concert to deliver its renowned industrial performance.

Exceptionally Low Friction & Self-Lubrication

The most significant factor in Teflon's wear resistance is its remarkably low coefficient of friction. This means moving parts slide against it with minimal resistance.

This self-lubricating quality drastically reduces heat buildup and material degradation over time, extending the service life of both the bushing and the machinery it supports.

Unmatched Chemical Inertness

Teflon is resistant to nearly all industrial chemicals, acids, and solvents. This chemical stability is crucial for durability in corrosive environments.

Where other materials would degrade, corrode, or swell, Teflon maintains its structural integrity, preventing premature failure and ensuring consistent performance.

Wide Temperature Stability

Teflon bushes operate effectively across a vast temperature range. They do not become brittle in cryogenic conditions or deform in high-heat applications.

This thermal resilience ensures predictable and reliable performance in processes that involve significant temperature fluctuations, from food processing to aerospace systems.

Operational Advantages of Teflon's Robustness

This combination of properties translates directly into tangible benefits for industrial operations, primarily by reducing equipment failure and associated costs.

Reduced Maintenance and Downtime

Because Teflon bushes resist wear and chemical attack, they have a very long lifespan. This reliability directly reduces the frequency of equipment shutdowns for replacement and maintenance.

The result is increased productivity and lower operational costs, as machinery remains in service for longer, uninterrupted periods.

Prevention of Contamination

Teflon's non-stick surface prevents viscous or sticky substances from building up on machinery components. This is a critical durability factor in industries like food and beverage or pharmaceuticals.

This quality allows for faster, cleaner production cycles without the risk of residue buildup or cross-contamination, improving overall efficiency and product quality.

Reliable Sealing Performance

In applications like O-rings, seals, and gaskets, Teflon's ability to maintain its shape and properties under pressure is vital.

It creates a dependable seal that prevents costly or hazardous leaks of fluids and gases, ensuring the stability and safety of high-pressure systems.

Understanding the Trade-offs

While exceptionally durable in many contexts, Teflon is not a universal solution. An objective assessment requires acknowledging its mechanical limitations.

Susceptibility to Creep (Cold Flow)

Under a high, sustained load, Teflon can be susceptible to "creep," or slow deformation over time. This must be considered in designs where precise tolerances are critical under constant static pressure.

Lower Compressive Strength vs. Metals

Teflon does not possess the same compressive strength or rigidity as a bronze or steel bushing. It excels in low-friction and chemical-resistance applications, not high-impact or extreme structural-load scenarios.

Higher Thermal Expansion

Compared to metals, Teflon has a higher coefficient of thermal expansion. Engineers must account for this in designs that experience wide temperature swings to avoid issues with binding or tolerance loss.

Making the Right Choice for Your Application

Selecting the correct material requires aligning its properties with your primary operational goal.

- If your primary focus is reducing friction in a corrosive environment: Teflon is the unparalleled choice due to its chemical inertness and self-lubricating properties.

- If your primary focus is managing extreme temperatures and preventing contamination: Teflon's thermal stability and non-stick surface make it ideal for food processing or high-temperature machinery.

- If your primary focus is supporting extremely high, static structural loads: You should evaluate whether Teflon's compressive strength is sufficient or if a metallic alternative is more appropriate.

Ultimately, understanding these core properties empowers you to leverage Teflon's exceptional durability where it will deliver the most significant operational value.

Summary Table:

| Property | Benefit | Industrial Advantage |

|---|---|---|

| Low Friction & Self-Lubrication | Reduces wear and heat buildup | Extended service life, reduced maintenance |

| Chemical Inertness | Resists acids, solvents, and corrosion | Reliable performance in harsh chemical environments |

| Wide Temperature Stability | Performs from cryogenic to high heat | Consistent operation in processes with temperature swings |

| Non-Stick Surface | Prevents material buildup and contamination | Ideal for food, pharma, and clean processes |

Need durable, high-performance PTFE components for your application?

KINTEK specializes in manufacturing precision PTFE components, including seals, liners, and custom bushings, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a solution tailored to your specific operational challenges, whether you need superior chemical resistance, thermal stability, or low-friction performance.

Contact our experts today to discuss how our PTFE components can enhance your equipment's reliability and reduce downtime.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications