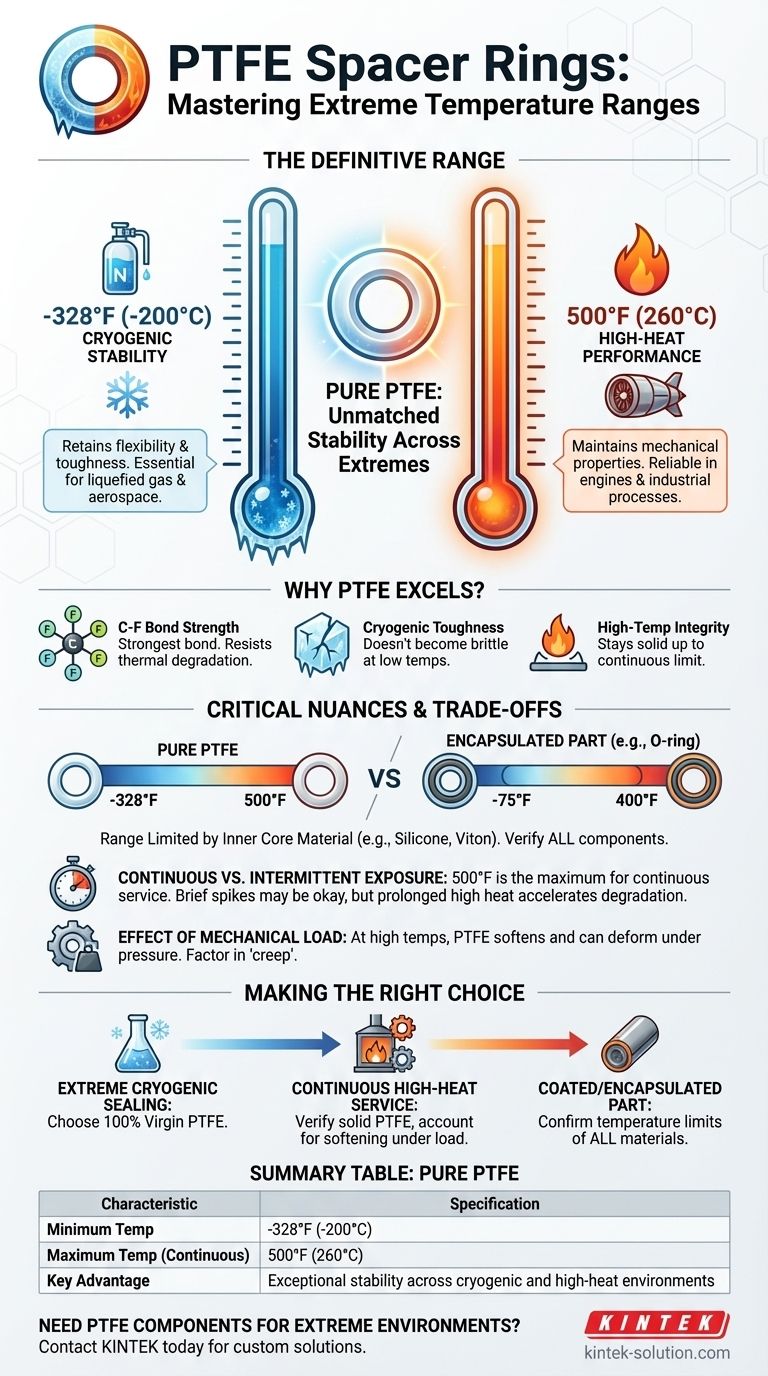

The definitive operating temperature range for pure PTFE spacer rings is from -328°F (-200°C) to 500°F (260°C). This exceptionally wide range makes PTFE a highly reliable material for components that must perform in both severe cryogenic conditions and high-heat environments without degrading. Its stability across these extremes is what sets it apart from nearly all other elastomers and polymers.

While the headline numbers are impressive, the true performance of a PTFE component depends on its specific composition. The distinction between pure PTFE, filled PTFE, and encapsulated parts is critical for ensuring reliability in your specific application.

Why PTFE Excels Across Extreme Temperatures

The remarkable thermal stability of Polytetrafluoroethylene (PTFE) is not an accident; it is a direct result of its unique molecular structure. Understanding this foundation is key to trusting the material in demanding conditions.

The Strength of Carbon-Fluorine Bonds

At its core, PTFE is composed of long chains of carbon atoms completely surrounded by fluorine atoms. The bond between carbon and fluorine is one of the strongest known in organic chemistry. This immense bond strength requires a great deal of thermal energy to break, which is why PTFE remains stable and inert at temperatures that would cause other polymers to melt or decompose.

Performance in Cryogenic Conditions

Many materials become extremely brittle and fracture at very low temperatures. PTFE, however, retains a significant amount of its flexibility and toughness even at cryogenic temperatures as low as -328°F (-200°C). This makes it an essential material for seals, gaskets, and spacers in liquefied gas applications and aerospace engineering.

Stability at High Temperatures

On the other end of the spectrum, PTFE maintains its crucial mechanical properties up to its continuous service limit of 500°F (260°C). While many plastics will soften and deform far below this point, PTFE parts remain solid and functional, providing a reliable seal or spacing element in engines, industrial processing, and high-temperature fluid systems.

Understanding the Trade-offs and Nuances

The widely cited temperature range is accurate for pure, or "virgin," PTFE. However, in practice, the specific form of the component can alter its effective service range. Ignoring these details is a common pitfall.

Pure PTFE vs. Encapsulated Parts

It is critical to distinguish between a solid PTFE spacer and a PTFE-encapsulated part, such as an O-ring. An encapsulated O-ring has a core of another material (like silicone or Viton) covered by a thin PTFE shell.

In these cases, the temperature range of the entire component is limited by the inner core material. For example, a common PTFE encapsulated O-ring may only be rated from -75°F to 400°F (-60°C to 205°C), a much narrower window than pure PTFE can handle.

Continuous vs. Intermittent Exposure

The 500°F (260°C) limit is generally considered the maximum for continuous service. PTFE can often withstand brief exposure to slightly higher temperatures without immediate failure. However, prolonged use above this recommended limit will accelerate the degradation of the material's mechanical properties, leading to premature failure.

The Effect of Mechanical Load

Temperature affects a material's physical properties. As PTFE approaches its upper temperature limit, it becomes softer and more susceptible to deformation under pressure (a phenomenon known as "creep"). When designing a system with PTFE spacers under a significant mechanical load at high temperatures, this potential for compression must be factored in.

Making the Right Choice for Your Goal

To select the correct material, match the component's full specification to the demands of your environment.

- If your primary focus is extreme cryogenic sealing (-200°C / -328°F): A spacer or seal made from 100% virgin PTFE is an excellent choice, as it is engineered to resist becoming brittle.

- If your primary focus is continuous high-heat service (up to 260°C / 500°F): Verify the part is solid PTFE and account for the material softening slightly if it will be under a heavy compressive load.

- If you are considering a coated or encapsulated part: You must confirm the temperature limits of all component materials, as the PTFE shell does not guarantee the entire part can withstand PTFE's full range.

Ultimately, understanding the full material composition of your component is the key to leveraging PTFE's remarkable thermal stability successfully.

Summary Table:

| Characteristic | Specification |

|---|---|

| Material | Pure (Virgin) PTFE |

| Minimum Temperature | -328°F (-200°C) |

| Maximum Temperature (Continuous) | 500°F (260°C) |

| Key Advantage | Exceptional stability across cryogenic and high-heat environments |

Need PTFE Components That Withstand Extreme Temperatures?

KINTEK specializes in manufacturing high-performance PTFE seals, spacer rings, liners, and custom labware for the most demanding environments in the semiconductor, medical, laboratory, and industrial sectors. We ensure precision and reliability, whether you need prototypes or high-volume production runs.

Contact KINTEK today to discuss your specific thermal requirements and get a custom solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech