Under ideal storage conditions, PTFE seals have an unlimited shelf life. This exceptional longevity is a direct result of the material's inherent chemical stability, which makes it virtually immune to the degradation factors that limit other polymer and elastomer seals.

The core takeaway is that while the PTFE material itself does not expire, its effectiveness as a seal is entirely dependent on maintaining its physical integrity through proper storage and handling, a factor often overlooked.

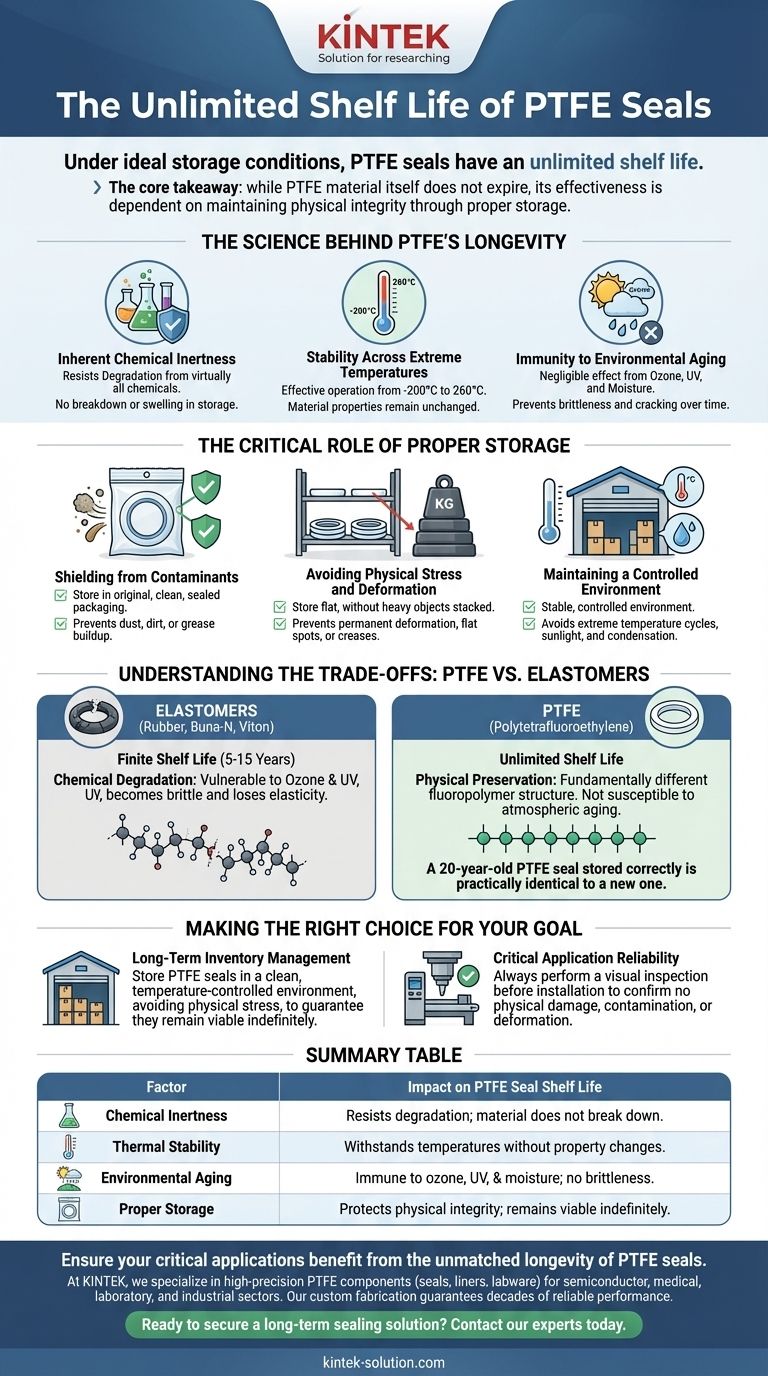

The Science Behind PTFE's Longevity

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer with a unique molecular structure. This structure is the key to its remarkable stability and long-term performance.

Inherent Chemical Inertness

PTFE is one of the most chemically inert materials known. It resists degradation from virtually all common industrial chemicals, including oils, acids, solvents, and bases.

This means that unlike rubber-based seals, PTFE will not break down or swell due to chemical reactions while sitting in storage.

Stability Across Extreme Temperatures

The material is highly resistant to temperature fluctuations. It can operate effectively in environments ranging from -200°C to 260°C (-328°F to 500°F).

This thermal stability ensures that the material properties do not change or degrade under typical warehouse storage temperatures.

Immunity to Environmental Aging

Factors that commonly age other materials, such as ozone, UV radiation, and moisture, have a negligible effect on PTFE.

This is a critical distinction from elastomers like nitrile or EPDM, which can become brittle or crack over time due to environmental exposure.

The Critical Role of Proper Storage

The "unlimited shelf life" of a PTFE seal is contingent on one crucial factor: protecting its physical form and cleanliness. The material won't degrade, but the seal can be rendered useless by improper handling.

Shielding from Contaminants

Seals must be stored in their original packaging or in clean, sealed bags. Dust, dirt, or grease on a sealing surface can create a leak path upon installation.

The non-stick properties of PTFE help prevent contaminant buildup, but clean storage is the best practice for ensuring performance.

Avoiding Physical Stress and Deformation

While flexible, PTFE can be permanently deformed under sustained pressure. Seals should be stored flat, without stacking heavy objects on top of them.

This prevents the development of flat spots or creases that would compromise the seal's ability to conform to a shaft or housing.

Maintaining a Controlled Environment

A stable, controlled environment is ideal. While PTFE is robust, avoiding extreme temperature cycles and direct sunlight preserves the packaging and eliminates any potential for condensation.

Understanding the Trade-offs: PTFE vs. Elastomers

The concept of shelf life is far more critical for elastomer seals (rubber) than for PTFE, and understanding why highlights the unique advantages of PTFE.

The Aging Process of Elastomers

Elastomer seals, such as Nitrile (Buna-N) or Viton (FKM), have a finite shelf life, typically ranging from 5 to 15 years.

Their polymer chains are vulnerable to attack by ozone and UV light, which causes them to become brittle and lose elasticity over time. This is a chemical degradation process.

PTFE's Structural Advantage

PTFE's fluoropolymer structure is fundamentally different and not susceptible to this type of atmospheric aging. Its shelf life is not a question of chemical breakdown but of physical preservation.

Therefore, a 20-year-old PTFE seal stored correctly is, for all practical purposes, identical to a new one. An equivalent elastomer seal would be highly suspect.

Making the Right Choice for Your Goal

Applying this knowledge correctly ensures long-term reliability for your equipment and inventory.

- If your primary focus is long-term inventory management: Store PTFE seals in a clean, temperature-controlled environment, avoiding physical stress, to guarantee they remain viable indefinitely.

- If your primary focus is critical application reliability: Always perform a visual inspection of any PTFE seal before installation, regardless of its age, to confirm there is no physical damage, contamination, or deformation from storage.

Ultimately, you can trust the material's stability over decades, but you must always verify the seal's physical condition before putting it into service.

Summary Table:

| Factor | Impact on PTFE Seal Shelf Life |

|---|---|

| Chemical Inertness | Resists degradation from oils, acids, and solvents; material does not break down. |

| Thermal Stability | Withstands temperatures from -200°C to 260°C without property changes. |

| Environmental Aging | Immune to ozone, UV, and moisture; no brittleness or cracking over time. |

| Proper Storage | Protects physical integrity; seals remain viable indefinitely when stored correctly. |

Ensure your critical applications benefit from the unmatched longevity of PTFE seals.

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—guarantees you receive components that deliver reliable performance for decades.

Ready to secure a long-term sealing solution for your equipment? Contact our experts today to discuss your specific requirements and discover how KINTEK's precision PTFE products can enhance your operational reliability.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What key factors contribute to long-term savings when using Teflon gland packing? Reduce Downtime and Maintenance Costs

- What makes Teflon gland fillers effective for sealing applications in the chemical industry? Superior Chemical Resistance and Reliability

- What types of cutting tools are recommended for machining PTFE? Achieve Clean Cuts and Tight Tolerances

- In what applications are PTFE slide bearings superior to conventional supports? Ensuring Predictable Movement for Critical Structures

- What are the benefits of CNC machining for PTFE parts? Achieve Precision and Performance

- What is the overall function of PTFE bushes in mechanical systems? Achieve Low-Friction, Maintenance-Free Operation

- Why are PTFE rotary shaft seals suitable for food and beverage processing? Ensure Purity & Performance

- What is a PTFE gasket and what are its primary properties? Unlock Superior Chemical and Thermal Sealing