In applications requiring controlled movement under immense loads, PTFE slide bearings are definitively superior to conventional supports like rollers, rockers, or lubricated plates. They are the preferred solution for large structures such as bridges, pipelines, and industrial facilities where managing thermal expansion, seismic shifts, or heavy reciprocating motion is critical for structural integrity. Their superiority stems from the unique material properties of PTFE, which ensure predictable, low-friction performance over the structure's entire lifespan.

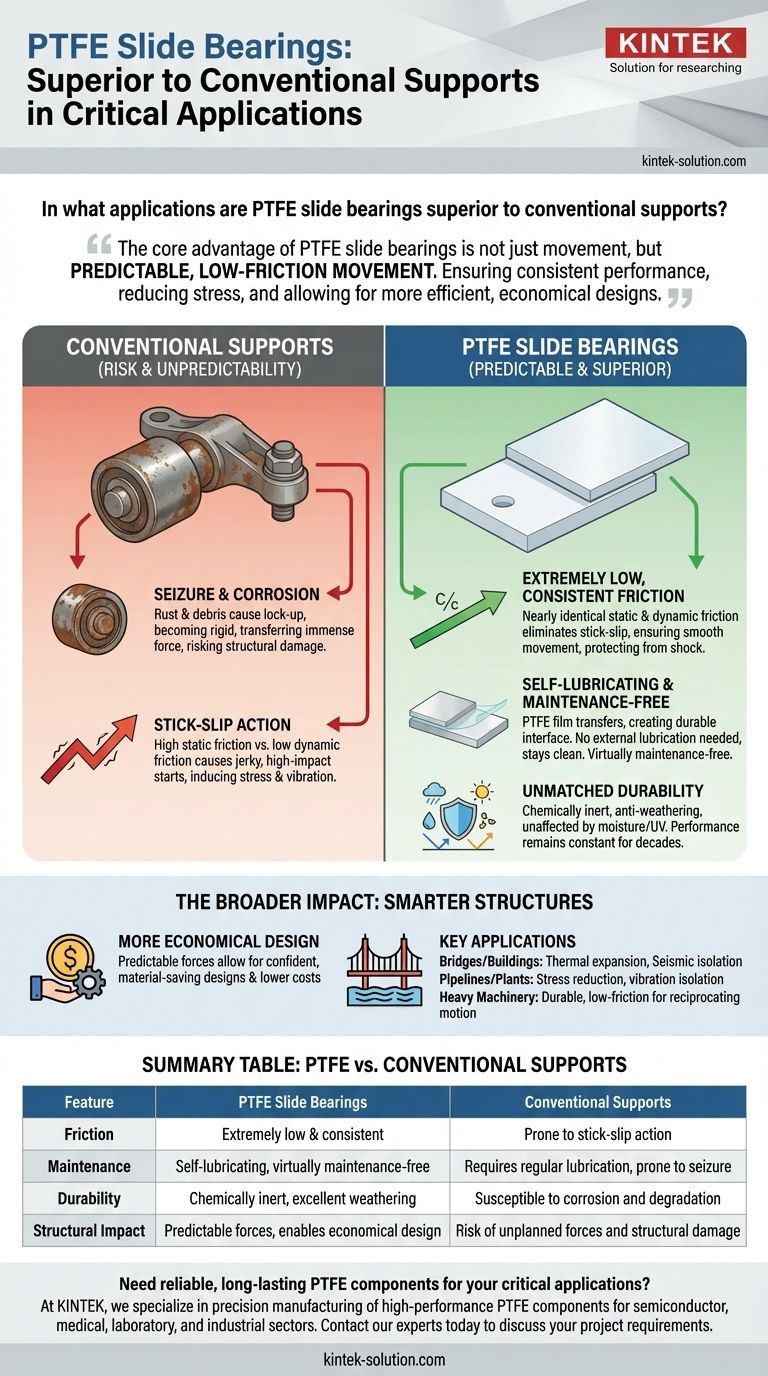

The core advantage of PTFE slide bearings is not just movement, but predictable, low-friction movement. Unlike mechanical supports that can corrode and seize, PTFE's inherent properties ensure consistent performance, reducing stress on the entire structure and allowing for more efficient, economical designs.

The Fundamental Problem with Conventional Supports

Conventional supports, such as steel rollers or rocker arms, are effective in theory but often fail in practice. They introduce significant risk and unpredictability into a structural system.

The Risk of Seizure and Corrosion

Metal-on-metal supports like rollers are highly susceptible to corrosion. Over time, rust and debris can cause them to seize or lock up, preventing the very movement they were designed to allow.

When a support seizes, it no longer functions as an expansion joint. Instead, it becomes a rigid connection, transferring immense and unplanned thermal or seismic forces directly into the supporting piers and foundations, which can lead to structural damage.

The Challenge of "Stick-Slip" Action

Even when functional, mechanical supports suffer from "stick-slip" action. This occurs when the force required to start a movement (static friction) is significantly higher than the force needed to keep it moving (dynamic friction).

This results in a jerky, high-impact start to any movement, which induces stress and vibration throughout the structure.

How PTFE Bearings Provide a Superior Solution

PTFE, or Polytetrafluoroethylene, overcomes these fundamental limitations through its inherent material properties. It doesn't rely on mechanical parts that can fail but on a stable, predictable sliding surface.

Extremely Low, Consistent Friction

PTFE has one of the lowest coefficients of friction of any solid material. This property is intrinsic to the material itself and does not degrade over time.

Crucially, the static and dynamic coefficients of friction for PTFE are nearly identical. This eliminates the dangerous "stick-slip" phenomenon, ensuring that movement begins smoothly and without the sudden release of energy, protecting the structure from shock loading.

Self-Lubricating and Maintenance-Free

PTFE bearings are self-lubricating. As the surfaces move against each other, a thin film of PTFE molecules transfers to the opposing plate, creating a durable PTFE-on-PTFE sliding interface.

This means they require no external lubrication, which would otherwise attract dirt and debris. This self-sufficiency makes them virtually maintenance-free—a critical advantage for components in inaccessible locations, like bridge piers.

Unmatched Durability

PTFE is chemically inert and features powerful anti-weathering characteristics. It is unaffected by moisture, UV radiation, or common industrial chemicals.

This ensures that its performance remains constant for decades, even in harsh marine or industrial environments where conventional steel supports would quickly degrade.

Understanding the Broader Impact

The choice of a bearing has consequences that extend beyond the support point itself. Using PTFE bearings enables engineers to design better, safer, and more cost-effective structures.

More Economical Structural Design

Because the frictional forces from PTFE bearings are low and, most importantly, predictable, engineers can design supporting structures with greater confidence.

They do not need to over-engineer columns and foundations to resist the massive, uncertain forces that a seized conventional bearing might generate. This reduction in required strength translates directly into material savings and lower construction costs.

Key Applications

- Bridges and Buildings: PTFE bearings safely accommodate thermal expansion and contraction cycles. In seismic zones, they act as isolators, allowing the superstructure to slide and dissipate earthquake energy.

- Pipelines & Petrochemical Plants: They allow long pipelines to expand and contract without building up dangerous stress. They also isolate equipment from vibration.

- Heavy Machinery: PTFE provides a durable, low-friction surface for heavy components that undergo constant reciprocating motion.

Making the Right Choice for Your Goal

When selecting a support system, the decision should be guided by the primary engineering demand of the structure.

- If your primary focus is accommodating thermal expansion: PTFE provides the most reliable, low-friction solution for managing predictable length changes in bridges and pipelines.

- If your primary focus is seismic resilience: PTFE slide bearings allow for controlled structural isolation, dissipating earthquake energy through sliding rather than transferring it to the substructure.

- If your primary focus is long-term reliability and cost-efficiency: PTFE's self-lubricating and anti-weathering properties reduce maintenance needs and allow for more economical supporting structure designs.

Ultimately, choosing PTFE slide bearings is a decision to prioritize predictable performance and long-term structural integrity over the inherent limitations of conventional mechanical supports.

Summary Table:

| Feature | PTFE Slide Bearings | Conventional Supports |

|---|---|---|

| Friction | Extremely low & consistent | Prone to stick-slip action |

| Maintenance | Self-lubricating, virtually maintenance-free | Requires regular lubrication, prone to seizure |

| Durability | Chemically inert, excellent weathering | Susceptible to corrosion and degradation |

| Structural Impact | Predictable forces, enables economical design | Risk of unplanned forces and structural damage |

Need reliable, long-lasting PTFE components for your critical applications?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components—including seals, liners, labware, and custom slide bearings. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get components that deliver predictable performance and structural integrity for the semiconductor, medical, laboratory, and industrial sectors.

Let us help you build a safer, more efficient structure. Contact our experts today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining