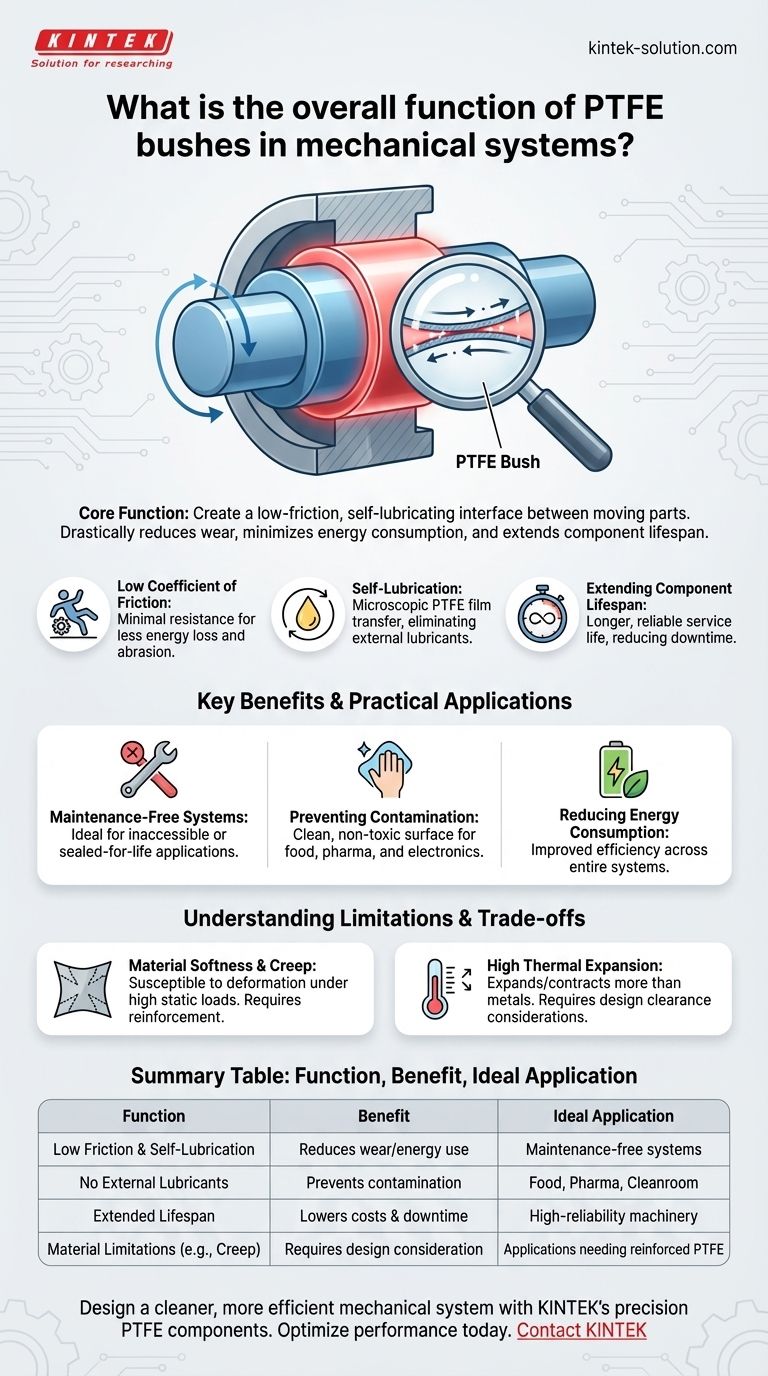

At its core, a PTFE bush serves a critical function in mechanical systems: to create a low-friction, self-lubricating interface between moving parts. This drastically reduces wear, minimizes energy consumption, and significantly extends the operational lifespan of the components it separates.

The decision to use a PTFE bush goes beyond simply reducing friction. It represents a strategic choice to design a system that is cleaner, more efficient, and often maintenance-free, especially in environments where traditional lubrication is impractical or forbidden.

The Core Principle: Overcoming Friction and Wear

The value of Polytetrafluoroethylene (PTFE) in mechanical applications stems from its unique molecular structure, which gives it several highly desirable properties.

Exceptionally Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material. This means that surfaces slide against it with minimal resistance.

This property directly translates to less energy being wasted as heat and less physical abrasion on the moving components, which is the primary cause of mechanical wear.

The Power of Self-Lubrication

PTFE bushes are inherently self-lubricating. As the components move, a microscopic film of PTFE is transferred to the mating surface, creating a smooth PTFE-on-PTFE contact.

This eliminates the need for external lubricants like oil or grease, which can be a significant advantage in system design.

Extending Component Lifespan

By combining low friction with self-lubrication, PTFE bushes create an ideal environment for moving parts.

The reduction in wear and heat generation directly leads to a longer, more reliable service life for the entire assembly, reducing downtime and replacement costs.

Key Benefits in Practical Applications

The fundamental properties of PTFE translate into tangible advantages that solve common engineering challenges across many industries.

Enabling Maintenance-Free Systems

Because they require no external lubrication, PTFE bushes are perfect for components that are difficult to access for regular maintenance.

They are often specified for "sealed-for-life" applications where reliability over a long period is paramount.

Preventing Product Contamination

In industries like food processing, pharmaceuticals, and electronics, any contamination from oils or greases can be catastrophic.

PTFE provides a clean, non-toxic bearing surface, ensuring the purity of the end product.

Reducing Energy Consumption

Systems operating with lower friction require less power to achieve the same output.

While the savings on a single joint may be small, they become significant when scaled across an entire machine or manufacturing plant, leading to improved energy efficiency.

Understanding the Trade-offs and Limitations

While highly effective, PTFE is not a universal solution. An objective assessment requires understanding its material limitations.

Material Softness and Deformation

Pure PTFE is a relatively soft material. Under high static loads, it can be susceptible to "creep" or cold flow, where the material slowly deforms over time.

This makes it unsuitable for applications with extremely high compressive forces unless it is reinforced with fillers like glass, carbon, or bronze.

High Thermal Expansion

PTFE expands and contracts with temperature changes more than most metals.

Engineers must account for this dimensional instability in their designs to ensure that proper clearances are maintained across the expected operating temperature range, preventing binding or excessive play.

Making the Right Choice for Your Goal

Selecting the right material requires matching its properties to your primary objective.

- If your primary focus is maintenance reduction or inaccessibility: PTFE is an ideal choice for creating reliable, "fit and forget" joints.

- If your primary focus is preventing product contamination: PTFE is often the mandatory standard for machinery in the food, medical, or clean-room sectors.

- If your primary focus is high load or high speed: Pure PTFE may not be suitable, and you should evaluate filled PTFE composites or alternative high-strength bearing materials.

By understanding both its unique benefits and its material limitations, you can leverage PTFE to design more efficient, reliable, and cleaner mechanical systems.

Summary Table:

| Key Function | Primary Benefit | Ideal Application |

|---|---|---|

| Low Friction & Self-Lubrication | Reduces wear and energy consumption | Maintenance-free or sealed systems |

| No External Lubricants | Prevents product contamination | Food, pharmaceutical, and cleanroom equipment |

| Extended Component Lifespan | Lowers downtime and replacement costs | High-reliability industrial machinery |

| Material Limitations (e.g., Creep) | Requires design consideration for high loads/speeds | Applications needing reinforced PTFE composites |

Design a cleaner, more efficient mechanical system with KINTEK's precision PTFE components.

As a leading manufacturer of high-performance PTFE seals, liners, labware, and custom components, KINTEK understands the critical role of low-friction materials in demanding environments. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the exact solution for maintenance reduction, contamination prevention, and extended equipment life.

Let's optimize your system's performance. Contact our engineering team today to discuss your specific application requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability