At its core, a Teflon sheet is an essential, non-stick protective barrier used in heat pressing. Its primary purpose is to shield the heated upper platen of your press from inks, adhesives, and other residues, while also protecting your garment from direct, intense heat that can cause scorching or discoloration.

The function of a Teflon sheet extends beyond simple protection; it is a critical tool for ensuring the consistency of your results, the quality of your finished product, and the long-term health of your equipment.

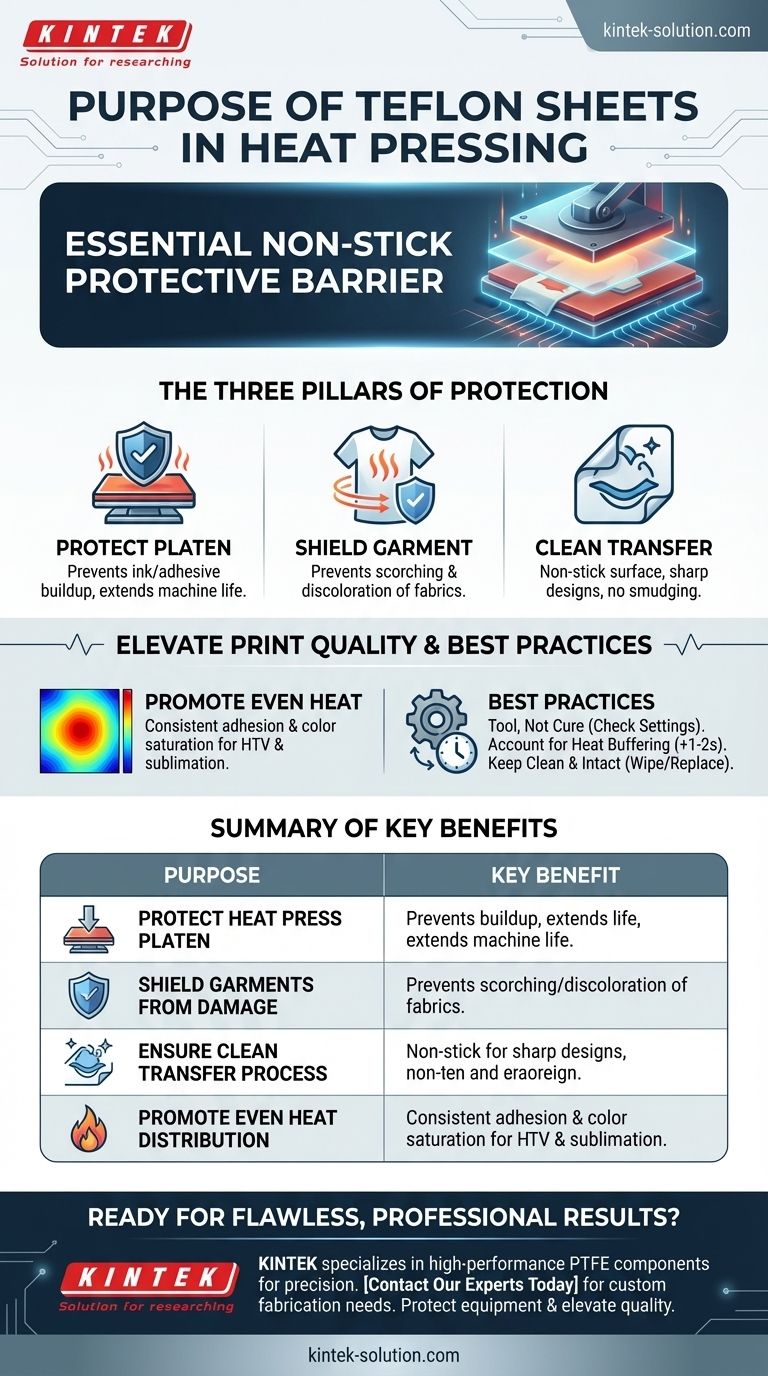

The Three Pillars of Protection

A Teflon sheet provides a crucial safety layer that benefits your machine, your material, and your overall process. Failing to use one introduces unnecessary risk at every stage.

Protecting Your Heat Press Platen

The most immediate purpose of the sheet is to protect your investment. Without a barrier, ink from sublimation or vinyl adhesive can melt and build up on the hot metal platen.

This residue is difficult to clean and, more importantly, can transfer onto the next project, causing stains and ruining subsequent garments. A Teflon sheet creates a barrier that catches this residue, keeping the platen pristine.

Shielding Your Garment from Damage

Direct contact with a high-temperature platen can scorch or yellow certain fabrics, especially light-colored polyesters and delicate materials.

The Teflon sheet acts as a buffer, diffusing the heat just enough to prevent this direct-contact damage while still allowing for a successful transfer.

Ensuring a Clean Transfer Process

The non-stick surface is a key feature. It ensures that neither the transfer paper nor the garment itself will adhere to the platen.

This allows for a clean lift after pressing, preventing smudges and ensuring that the design remains sharp and intact.

How a Teflon Sheet Elevates Print Quality

Beyond its protective duties, a Teflon sheet actively contributes to a more professional and consistent final product.

Promoting Even Heat Distribution

While a quality heat press should have even heating, minor fluctuations can still occur. A Teflon sheet helps distribute the heat more evenly across the entire surface of your design.

This leads to more consistent adhesion for heat transfer vinyl (HTV) and more uniform color saturation for sublimation transfers.

Preventing Unwanted Surface Textures

In some cases, the texture of the heat platen's coating can subtly imprint onto certain materials. The smooth surface of the Teflon sheet ensures a flawless, unblemished finish on your design.

Understanding the Trade-offs and Best Practices

While overwhelmingly beneficial, it's important to understand how a Teflon sheet fits into your workflow.

It's a Tool, Not a Cure-All

A Teflon sheet will not fix incorrect settings. If your temperature is too high, your pressure is wrong, or your timing is off, the transfer can still fail. It is a protective aid, not a substitute for proper technique.

Account for Minor Heat Buffering

The sheet can absorb a minuscule amount of heat. For most applications, this is negligible. However, some advanced users may add a second or two to their press time to compensate, ensuring a perfect transfer.

Keep It Clean and Intact

The sheet itself must be kept clean. Wipe off any ink or adhesive residue between presses. A damaged sheet with scratches or gouges can transfer those imperfections to your print and should be replaced.

Making the Right Choice for Your Goal

Using a Teflon sheet should be standard practice, but it becomes absolutely critical in specific situations.

- If your primary focus is equipment longevity: Always use a sheet to prevent residue buildup and make cleanup effortless, extending the life of your press.

- If you are working with sublimation or white/light fabrics: It is non-negotiable for preventing ink blow-by from staining the platen and for shielding the fabric from scorch marks.

- If you are layering multiple colors of HTV: A sheet is essential to protect previously applied layers from direct heat and prevent the platen from picking up exposed adhesive.

- If your goal is consistent, professional-grade quality: The sheet ensures a clean release and even heat distribution, eliminating common points of failure.

Ultimately, integrating a Teflon sheet into every press is the mark of a deliberate and professional workflow.

Summary Table:

| Purpose | Key Benefit |

|---|---|

| Protect Heat Press Platen | Prevents ink/adhesive buildup, extends machine life. |

| Shield Garments from Damage | Prevents scorching and discoloration of delicate fabrics. |

| Ensure Clean Transfer Process | Non-stick surface prevents smudging for sharp designs. |

| Promote Even Heat Distribution | Leads to consistent adhesion and color saturation. |

Ready to achieve flawless, professional results with every press? The right materials make all the difference. KINTEK specializes in manufacturing high-performance PTFE (Teflon) components, including custom sheets and liners, for industries that demand precision and durability. Whether you're a manufacturer of heat press machines or a large-scale printing operation, we can provide custom fabrication from prototypes to high-volume orders. Protect your equipment and elevate your product quality – contact our experts today to discuss your needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are some unusual industries where PTFE bellows are utilized? Mastering Extreme Purity, Heat, and Precision

- How does PTFE's thermal expansion and contraction affect its machining and application? Master Dimensional Stability

- What industries benefit from TFE Encapsulated O-Rings and Gaskets? Ensure Reliability in Demanding Applications

- What are the main features of PTFE bushings? Unlock Superior Performance in Harsh Environments

- How do PTFE-lined valves benefit the environment? Prevent Pollution and Reduce Waste

- What are the advantages of PTFE gaskets? Superior Sealing for Extreme Chemical & Thermal Environments

- How does Teflon coating contribute to machinery safety and efficiency? Extend Asset Life and Reduce Downtime

- What additional benefits do PTFE rotary shaft seals offer? Achieve Superior Reliability in Extreme Conditions