In short, PTFE gaskets offer a powerful combination of benefits for demanding industrial applications, centered on their near-universal chemical resistance, extremely wide operating temperature range, and exceptionally low-friction, non-stick surface. These core attributes make them a default choice for sealing systems that handle aggressive chemicals or operate in extreme thermal conditions where other materials would quickly fail.

PTFE is a high-performance sealing material designed to solve problems in extreme environments. However, its primary advantage of chemical inertness is balanced by a critical physical limitation—a tendency to creep under load—which must be understood and managed for successful application.

Why PTFE is a Go-To Material for Extreme Environments

Polytetrafluoroethylene (PTFE) is not just another polymer; it is a specialized fluoropolymer engineered for performance where conventional materials cannot survive. Its unique molecular structure is the source of its most significant advantages.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, including the most aggressive acids, bases, and solvents. This makes it an ideal sealing material for chemical processing, pharmaceutical, and laboratory applications.

Its chemical inertness means the gasket will not degrade, swell, or contaminate the process media, ensuring both the integrity of the seal and the purity of the product.

Extreme Temperature Stability

PTFE gaskets perform reliably across a vast temperature spectrum, typically from -200°C to +260°C (-328°F to +500°F).

This stability allows them to be used in everything from cryogenic applications to high-temperature processing lines, providing a single material solution for systems with significant temperature fluctuations.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, creating a non-stick, anti-adhesion surface.

This property prevents process media from sticking to the gasket, which simplifies cleaning and prevents buildup that could compromise the seal. It is also highly beneficial in applications with rotating or sliding parts.

Key Supporting Advantages of PTFE

Beyond its core strengths, PTFE provides several other properties that make it a versatile and reliable choice for sealing.

Superior Sealing and Durability

PTFE is flexible and can conform to irregular or uneven flange surfaces, creating a tight and reliable seal against both gas and liquid leakage.

It demonstrates good wear and fatigue resistance, holding up well under repeated compression cycles without becoming brittle or degrading.

Excellent Electrical Insulation

PTFE is an outstanding electrical insulator, making it a valuable choice for applications where the gasket must also prevent electrical conductivity between flange faces.

High Purity for Sensitive Applications

Certain grades of PTFE are non-toxic and comply with FDA standards, making them safe for use in food, beverage, and pharmaceutical manufacturing. These high-purity gaskets do not leach contaminants into the system.

Understanding the Critical Trade-off: Creep

While PTFE's advantages are significant, no material is without its limitations. For PTFE, the primary trade-off is its susceptibility to creep, also known as cold flow.

What is Creep?

Creep is the tendency of a material to deform slowly and permanently over time when subjected to a constant mechanical stress, such as the pressure from a bolted flange.

Even at room temperature, a PTFE gasket can "flow" away from the point of highest pressure.

The Impact on Sealing Performance

This creep can lead to a loss of bolt torque and a reduction in sealing stress on the gasket. In applications with high pressure, temperature cycling, or significant vibration, this can eventually result in a leak.

How to Mitigate Creep

This weakness is well-understood and has been addressed through material engineering. Filled PTFE (which includes materials like glass or carbon) and expanded PTFE (ePTFE) are designed specifically to resist creep while retaining the desirable properties of virgin PTFE.

Making the Right Choice for Your Application

Selecting the correct gasket requires matching the material's properties to the demands of the service.

- If your primary focus is aggressive chemicals or high purity: Virgin PTFE is an excellent first choice due to its near-universal chemical resistance and FDA-compliant options.

- If your application involves an extreme temperature range: PTFE is one of the few materials that can reliably handle both cryogenic lows and high process heat up to 260°C (500°F).

- If you are dealing with high pressure or thermal cycling: Choose a creep-resistant option like filled or expanded PTFE (ePTFE) to ensure a durable, long-lasting seal.

Ultimately, understanding both the exceptional strengths and the inherent limitations of PTFE is the key to leveraging it effectively in your system.

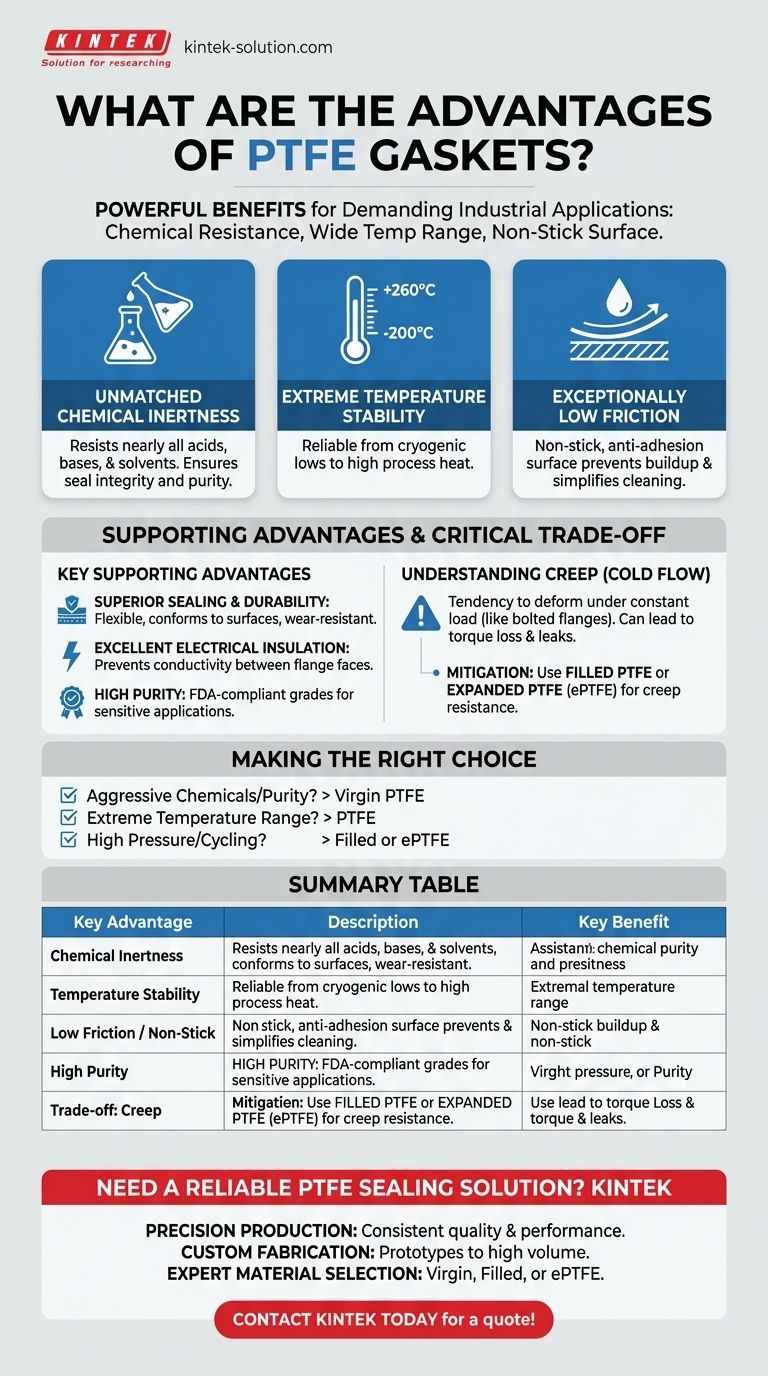

Summary Table:

| Key Advantage | Description | Key Benefit |

|---|---|---|

| Chemical Inertness | Resistant to nearly all acids, bases, and solvents. | Ensures seal integrity and process purity. |

| Temperature Stability | Operates from -200°C to +260°C (-328°F to +500°F). | A single solution for cryogenic to high-heat applications. |

| Low Friction / Non-Stick | Prevents media adhesion and simplifies cleaning. | Reduces maintenance and prevents seal compromise. |

| High Purity | FDA-compliant grades available. | Ideal for pharmaceutical, food, and beverage industries. |

| Trade-off: Creep | Can deform under constant stress. | Mitigated by using filled or expanded PTFE (ePTFE). |

Need a Reliable PTFE Sealing Solution?

PTFE gaskets from KINTEK are engineered to solve your most challenging sealing problems in extreme chemical and thermal environments. We specialize in manufacturing high-performance PTFE components, including custom gaskets, seals, liners, and labware.

We provide:

- Precision Production: Ensuring consistent quality and reliable performance.

- Custom Fabrication: From initial prototypes to high-volume production runs.

- Expert Material Selection: Helping you choose the right PTFE formulation (virgin, filled, or ePTFE) to combat creep and meet your specific pressure, temperature, and chemical requirements.

Our components are trusted in: Semiconductor, Medical, Laboratory, Industrial, and other specialized industries.

**Let us help you achieve a leak-free, durable seal. Contact KINTEK today for a quote or to discuss your application needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials