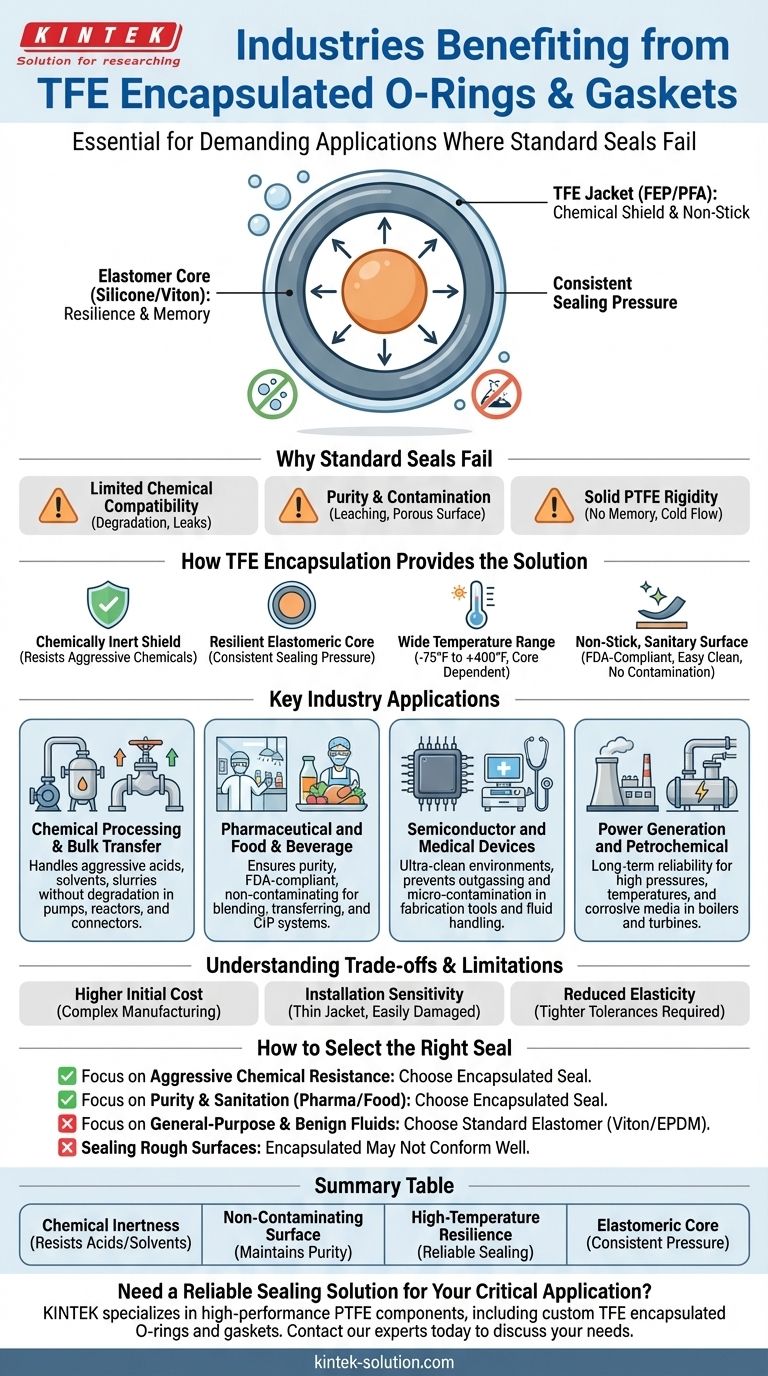

TFE encapsulated seals are specified in a wide array of demanding industries where standard seals would quickly fail. They are essential in sectors such as chemical processing, pharmaceuticals, food and beverage, and semiconductor manufacturing. The core reason for their adoption is the unique combination of extreme chemical resistance and high-purity, non-stick surfaces, making them indispensable for handling aggressive or sensitive materials.

The central challenge in industrial sealing is finding a material that is both chemically inert and elastically resilient. TFE encapsulated O-rings and gaskets solve this by combining the robust chemical shield of TFE (Teflon) with the flexible, reliable sealing pressure of an elastomer core, delivering a "best of both worlds" solution for critical applications.

The Core Problem: Why Standard Seals Fail

Before understanding the benefits of encapsulation, it's crucial to recognize the limitations of traditional sealing materials. Most sealing failures occur when the application environment exceeds the material's capabilities.

Limited Chemical Compatibility

Standard elastomers like EPDM, Viton, or Nitrile have a finite range of chemical resistance. When exposed to aggressive acids, solvents, or other corrosive agents, they swell, harden, or degrade, leading to seal failure, leaks, and costly downtime.

The Purity and Contamination Challenge

In industries like pharmaceuticals, food processing, and semiconductors, preventing contamination is non-negotiable. Many standard elastomers can leach trace elements into the process media. Their surfaces can also be porous, trapping material and making effective cleaning difficult.

The Rigidity of Solid PTFE

While solid PTFE (Teflon) offers near-universal chemical resistance, it is a rigid material. It lacks the "memory" and elasticity of rubber, meaning it doesn't spring back into shape effectively. This can lead to poor sealing under pressure fluctuations and a phenomenon known as "cold flow," where the material slowly deforms over time.

How TFE Encapsulation Provides the Solution

An encapsulated seal is a composite design: an elastomeric "core" O-ring is seamlessly covered by a thin jacket of TFE (Teflon). This construction directly addresses the weaknesses of other materials.

The Chemically Inert Shield

The outer TFE (typically FEP or PFA) jacket acts as an impenetrable barrier. It is chemically inert to nearly all industrial chemicals and solvents, even at elevated temperatures. This jacket protects the vulnerable elastomer core from chemical attack.

The Resilient Elastomeric Core

The inner core, typically made of Silicone or Viton (FKM), provides the elasticity and memory required for a reliable seal. This core constantly pushes out against the TFE jacket, maintaining consistent sealing pressure against the hardware surfaces.

A Wide Operational Temperature Range

The choice of core material determines the seal's temperature capabilities. A silicone core allows for operation in a very broad range (e.g., -75°F to +400°F), while a Viton core offers excellent compression set resistance at the higher end of the temperature spectrum.

The Non-Stick, Sanitary Surface

The TFE jacket has an extremely low coefficient of friction, which eases installation and prevents galling. More importantly, its non-stick, non-porous surface makes it easy to clean and sterilize, preventing product buildup and contamination, which is why it's often FDA-compliant.

Key Industry Applications

The unique properties of TFE encapsulated seals make them the default choice in several critical industries.

Chemical Processing and Bulk Transfer

This is the primary market. These seals are used in pumps, valves, reactors, and hose connectors for transferring everything from aggressive acids and solvents to mining slurries and agricultural chemicals without degradation.

Pharmaceutical and Food & Beverage

Here, the focus is on purity. The FDA-compliant, non-contaminating surface is essential for blending raw materials, transferring perfumes, and in any process where seal material cannot interact with the product. They are ideal for systems that undergo frequent Clean-In-Place (CIP) procedures.

Semiconductor and Medical Devices

In these ultra-clean environments, preventing outgassing and micro-contamination is paramount. Encapsulated seals provide a pure, stable sealing surface in fabrication tools, water treatment systems, and medical fluid handling equipment.

Power Generation and Petrochemical

In applications involving high pressures, high temperatures, and corrosive media—such as in boilers, turbines, and chemical pipelines—the combination of chemical resistance and resilient sealing provides long-term reliability.

Understanding the Trade-offs and Limitations

While highly effective, TFE encapsulated seals are not a universal solution. An objective assessment requires acknowledging their limitations.

Higher Initial Cost

These are complex, multi-material seals, and their manufacturing process makes them significantly more expensive than standard, single-material elastomeric O-rings. Their value is justified by preventing costly failures and extending service life.

Installation Sensitivity

The TFE jacket is relatively thin and can be scratched or damaged during installation if proper care is not taken. Any breach in the jacket compromises the seal's chemical resistance entirely, as the aggressive media can then reach and destroy the inner core.

Reduced Elasticity

Compared to a standard elastomeric O-ring, an encapsulated ring has less "stretch." This means the hardware grooves they fit into must be designed with tighter tolerances. They are less forgiving of surface imperfections.

How to Select the Right Seal

Choosing the correct seal depends entirely on the demands of your specific application.

- If your primary focus is aggressive chemical resistance: An encapsulated seal is the superior choice to prevent chemical degradation and ensure long-term system integrity.

- If your primary focus is purity and sanitation (Pharma/Food): The non-contaminating, easy-to-clean surface of a TFE encapsulated seal is essential for meeting regulatory standards and ensuring product quality.

- If your primary focus is general-purpose sealing with benign fluids: A standard elastomeric O-ring (like Viton or EPDM) is often more cost-effective and perfectly sufficient for the task.

- If you are sealing rough or imperfect surfaces: The lower flexibility of an encapsulated ring may be a liability; a softer, fully elastomeric seal may conform better to surface irregularities.

Ultimately, choosing an encapsulated seal is an investment in reliability for environments where failure is not an option.

Summary Table:

| Key Property | Benefit for Industries |

|---|---|

| Chemical Inertness | Resists aggressive acids, solvents, and corrosive media in chemical processing. |

| Non-Contaminating Surface | Maintains product purity in pharmaceuticals, food & beverage, and semiconductors. |

| High-Temperature Resilience | Ensures reliable sealing in power generation and petrochemical applications. |

| Elastomeric Core | Provides consistent sealing pressure and compensates for system fluctuations. |

Need a reliable sealing solution for your critical application?

KINTEK specializes in manufacturing high-performance PTFE components, including custom TFE encapsulated O-rings and gaskets. Our seals are engineered to provide the chemical resistance and purity required by the semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, ensuring precision and reliability for your most demanding environments. Contact our experts today to discuss your specific needs and ensure your systems are protected against failure.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What is the overall operating temperature range for PTFE seals, gaskets, and O-rings? Achieve Sealing Integrity from -200°C to +260°C

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- What are the key advantages of PTFE rotary seals over traditional rubber seals? Superior Performance in Extreme Conditions

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance