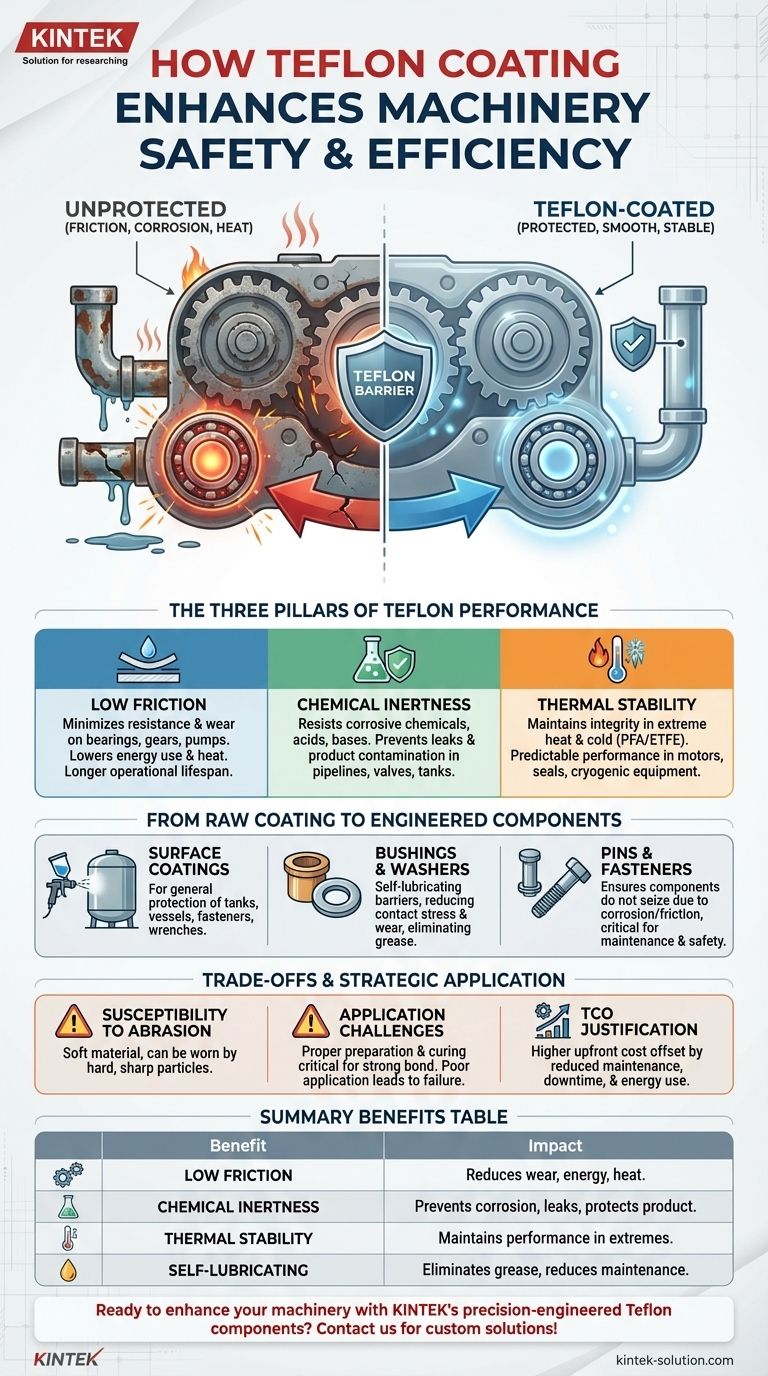

Teflon coatings fundamentally enhance machinery safety and efficiency by creating an exceptionally durable, low-friction, and chemically inert barrier on critical components. This protective layer directly mitigates the primary causes of mechanical failure—friction, corrosion, and extreme temperatures—leading to reduced wear, lower maintenance requirements, and more reliable, continuous operation.

The true value of Teflon in an industrial setting is its ability to decouple a component's structural material from its operating environment. This effectively insulates the machinery from the three main drivers of degradation: friction, chemical attack, and thermal stress, turning a maintenance liability into a predictable asset.

The Three Pillars of Teflon's Performance

To understand Teflon's impact, you must first understand the three core properties that make it so effective in industrial applications. These properties work in concert to protect the underlying machinery.

Reducing Friction to Minimize Wear and Energy Loss

Teflon possesses an extremely low coefficient of friction, meaning surfaces can slide against each other with minimal resistance. This is the property most people associate with non-stick pans, but in machinery, its implications are profound.

This low-friction surface dramatically reduces the mechanical wear on moving parts like bearings, gears, and pump components. Less wear means a longer operational lifespan and fewer replacements. It also reduces the energy required to operate the machinery and minimizes heat generation, a critical safety factor in high-speed equipment.

Resisting Corrosion and Chemical Attack

Teflon is chemically inert, making it almost completely immune to attack from corrosive chemicals, acids, and bases. This is essential for safety and efficiency in industries like chemical manufacturing.

By coating pipelines, valves, containers, and hoses, you can use cost-effective structural metals while ensuring the material in contact with the process fluid will not degrade. This prevents catastrophic leaks, protects product purity, and extends the life of expensive infrastructure, avoiding costly downtime for replacement.

Maintaining Stability at Extreme Temperatures

Industrial processes often involve extreme heat or cold, which can cause other materials to fail by becoming brittle, melting, or cracking. Teflon coatings, particularly grades like PFA and ETFE, maintain their structural integrity and protective properties across a wide temperature range.

This stability ensures that components perform predictably under thermal stress. Whether it's a bushing in a high-temperature motor or a seal in cryogenic equipment, the coating will not fail, ensuring the machine operates safely and consistently.

From Raw Coating to Engineered Components

Teflon is not just applied as a paint-like layer. It is also engineered into discrete components that solve specific mechanical problems.

Surface Coatings for General Protection

The most common application is a thin protective coating on a metal or glass substrate. This is used to add durability and chemical resistance to everything from large tanks and vessels to small parts like bolts, fasteners, and wrenches, protecting them from their operating environment.

Bushings and Washers for Smooth Operation

Teflon bushings and washers are vital components placed at high-friction points within machinery, such as in motor housings, pump assemblies, and conveyor systems.

These parts act as a self-lubricating barrier between moving metal surfaces. They significantly reduce contact stress and wear, often completely eliminating the need for grease-based lubricants. This results in a cleaner, lower-maintenance solution.

Pins and Fasteners for Reliability

Even small components like positioning pins and safety pins benefit from a Teflon coating. The coating ensures these fasteners do not seize up due to corrosion or friction, guaranteeing they can be installed, removed, and function correctly, which is critical for both routine maintenance and safety mechanisms.

Understanding the Trade-offs and Limitations

While highly effective, Teflon is not a universal solution. An objective assessment requires understanding its limitations.

Susceptibility to Abrasive Wear

Teflon is a relatively soft material. While it excels in reducing sliding friction, it can be quickly damaged by hard, sharp particles. In environments with significant abrasive contaminants (like sand or metal filings), the coating can be scratched or worn away, diminishing its effectiveness.

Application and Bonding Challenges

The performance of a Teflon coating is heavily dependent on the quality of its application. Proper surface preparation and curing are critical for achieving a strong bond with the substrate. A poorly applied coating can flake or peel, leading to premature failure and potentially contaminating the system.

Upfront Cost vs. Total Cost of Ownership

Teflon-coated parts and specialized components are typically more expensive upfront than their uncoated counterparts. The economic justification lies in the Total Cost of Ownership (TCO). The investment is offset by reduced maintenance, less frequent part replacement, decreased downtime, and lower energy consumption over the machine's life.

Making the Right Choice for Your Operation

Use Teflon strategically where its properties provide the greatest return on investment for safety and efficiency.

- If your primary focus is extending asset life: Use Teflon coatings to protect parts from corrosion and deploy Teflon bushings and washers to reduce mechanical wear in high-friction interfaces.

- If your primary focus is reducing maintenance costs: Target applications where Teflon's self-lubricating properties can eliminate the need for regular greasing, especially in hard-to-reach areas or food-grade environments.

- If your primary focus is improving operational safety: Apply Teflon in systems handling corrosive chemicals or where component failure from seizure or overheating poses a significant risk to personnel or production.

By strategically applying Teflon where its unique properties solve a specific problem, you can transform machinery maintenance from a reactive chore into a proactive strategy for boosting reliability and performance.

Summary Table:

| Teflon Benefit | Key Impact on Machinery |

|---|---|

| Low Friction | Reduces wear on moving parts, lowers energy consumption, and minimizes heat generation. |

| Chemical Inertness | Prevents corrosion and leaks in chemical processes, protecting product purity and infrastructure. |

| Thermal Stability | Maintains performance under extreme temperatures, ensuring reliable operation in harsh conditions. |

| Self-Lubricating | Eliminates the need for grease in components like bushings and washers, reducing maintenance. |

Ready to enhance your machinery's reliability and safety with precision-engineered Teflon components?

At KINTEK, we specialize in manufacturing high-performance PTFE (Teflon) components—including custom seals, liners, bushings, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get durable, chemically inert, and low-friction solutions tailored to your operational challenges.

Contact us today to discuss how our Teflon components can reduce your maintenance costs, extend equipment lifespan, and boost efficiency. Let’s build a safer, more reliable system together.

Get in touch with our experts now!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industries commonly use glass-filled PTFE rods? Enhance Performance in Aerospace, Medical & More

- How does the PTFE lining in butterfly valves protect against harsh conditions? Ensure Long-Term Reliability

- What are the disadvantages of using PTFE O-Rings? When Rigidity and Lack of Elasticity Cause Leaks

- What temperature can heat-resistant Teflon sheets withstand? Up to 500°F for Reliable Performance

- What is the pH range that PTFE Enveloped Gaskets can handle? Achieve Universal Chemical Resistance

- What are the properties of stainless steel-filled PTFE bushings? Achieve Superior Strength & Durability

- What role do Teflon PTFE sheets play in sewing projects? Achieve Flawless, Professional Results

- How can sticking or hard operation of a PTFE butterfly valve be resolved? A 3-Step Guide to Restore Smooth Performance