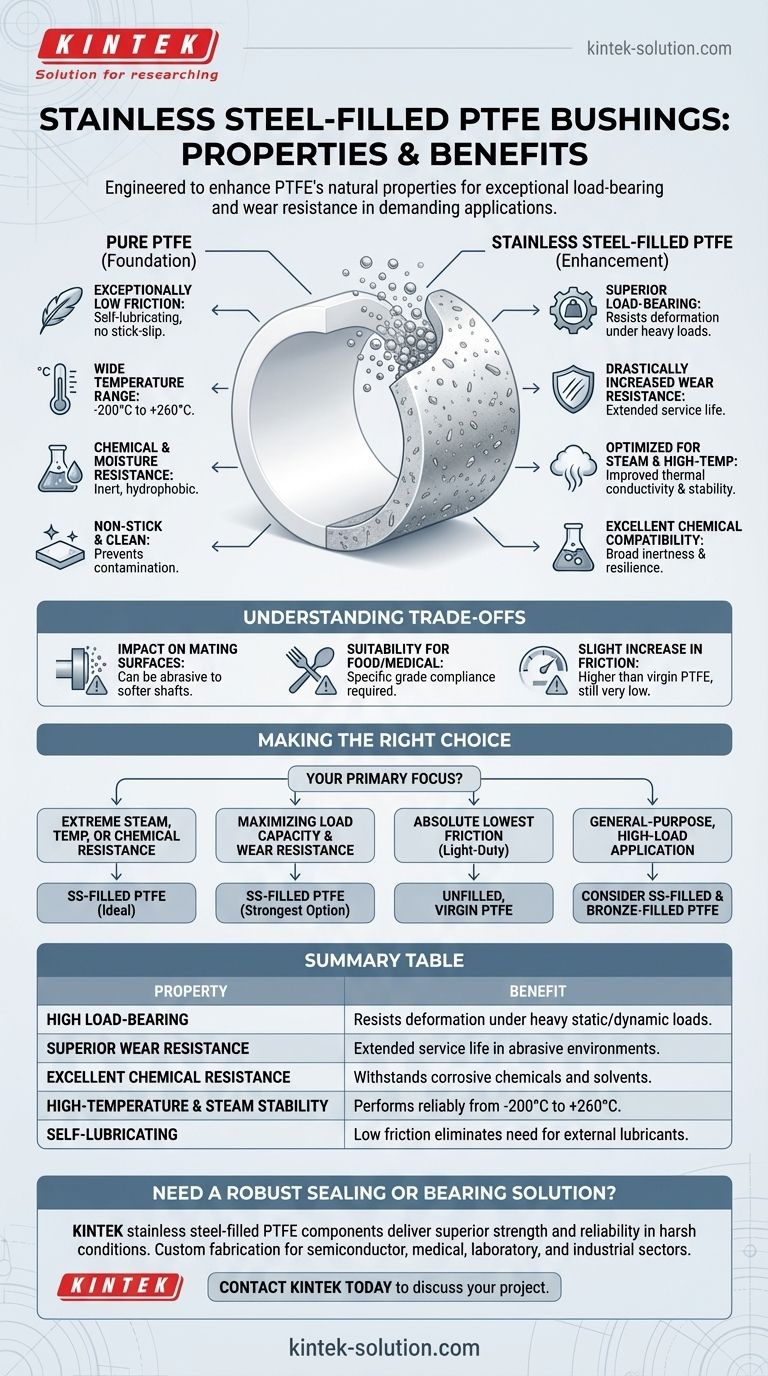

To be precise, stainless steel-filled PTFE bushings are engineered to enhance the natural properties of PTFE, resulting in a material with exceptionally high load-bearing capability and wear resistance. They are specifically designed for demanding applications, offering better chemical resistance than bronze-filled variants and superior performance in high-temperature and steam service environments.

The core takeaway is that adding stainless steel to PTFE transforms a soft, low-friction polymer into a robust composite material. This enhancement allows the bushing to maintain PTFE's benefits—like self-lubrication and chemical inertness—while withstanding heavy loads and harsh industrial conditions that pure PTFE cannot.

The Foundation: Core Properties of PTFE

To understand the filled variant, we must first appreciate the base material. Polytetrafluoroethylene (PTFE) is a remarkable polymer with a unique combination of characteristics.

### Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This gives the bushings self-lubricating properties, eliminating the need for external grease or oil and preventing stick-slip issues.

### Wide Temperature Range

The material remains stable and functional across a vast temperature spectrum, typically from -200°C to +260°C (-328°F to +500°F).

### Chemical and Moisture Resistance

Virgin PTFE is almost completely inert, resisting nearly all industrial chemicals and solvents. It is also hydrophobic, meaning it repels water and moisture.

### Non-Stick and Clean Surface

The inherent non-adhesive properties of PTFE prevent contamination and make surfaces easy to clean, a significant advantage in food production or medical applications.

The Enhancement: Adding Stainless Steel

While pure PTFE is excellent in many ways, it is mechanically soft. Adding a stainless steel filler fundamentally improves its physical strength and durability.

### Drastically Increased Wear Resistance

The stainless steel particles distributed throughout the PTFE matrix provide a reinforcing effect. This makes the bushing much more resistant to wear and abrasion, significantly extending its service life under load.

### Superior Load-Bearing Capability

This is the primary reason for choosing a filled PTFE. The steel filler helps the bushing resist deformation, or "cold flow," under heavy static or dynamic loads.

### Optimized for Steam and High Temperatures

Stainless steel-filled PTFE is the preferred choice for applications involving steam or constant high temperatures. The steel filler improves thermal conductivity and dimensional stability in these harsh conditions.

### Excellent Chemical Compatibility

This composite combines the broad chemical inertness of PTFE with the resilience of stainless steel, resulting in a material that stands up exceptionally well to corrosive environments.

Understanding the Trade-offs

No material choice is without compromise. While stainless steel fillers provide immense benefits, it's critical to understand the potential downsides for certain applications.

### Impact on Mating Surfaces

The hard stainless steel particles can be more abrasive to softer shaft materials compared to unfilled or bronze-filled PTFE. Careful consideration of shaft hardness and surface finish is required.

### Suitability for Food or Medical Use

While pure PTFE is non-toxic and often used in food and medical applications, the addition of a filler complicates this. The specific grade of stainless steel must be verified as compliant for any such regulated use.

### Slight Increase in Friction

While still very low, the coefficient of friction for a stainless steel-filled bushing is typically slightly higher than that of virgin PTFE. The filler adds mechanical strength at a minor cost to slipperiness.

Making the Right Choice for Your Goal

Selecting the correct bushing material depends entirely on the demands of your specific application.

- If your primary focus is extreme steam, temperature, or chemical resistance: Stainless steel-filled PTFE is an ideal choice, often outperforming other filled variants.

- If your primary focus is maximizing load capacity and wear resistance: Stainless steel-filled PTFE is one of the strongest and most durable options in the PTFE family.

- If your primary focus is the absolute lowest friction for a light-duty application: Unfilled, virgin PTFE may be the more suitable and cost-effective solution.

- If your primary focus is a general-purpose, high-load application: Consider both stainless steel-filled and bronze-filled PTFE, as each has a distinct cost-performance profile.

Ultimately, choosing stainless steel-filled PTFE is a strategic decision for when you need to retain the key benefits of PTFE in a demanding industrial environment that requires superior mechanical strength.

Summary Table:

| Property | Benefit |

|---|---|

| High Load-Bearing | Resists deformation under heavy static/dynamic loads. |

| Superior Wear Resistance | Extended service life in abrasive environments. |

| Excellent Chemical Resistance | Withstands corrosive chemicals and solvents. |

| High-Temperature & Steam Stability | Performs reliably from -200°C to +260°C. |

| Self-Lubricating | Low friction eliminates need for external lubricants. |

Need a robust sealing or bearing solution for a demanding application?

Stainless steel-filled PTFE components from KINTEK are engineered to deliver superior mechanical strength, chemical resistance, and long-term reliability in the harshest conditions. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a precision part that meets your exact specifications.

Contact KINTEK today to discuss your project requirements and discover how our advanced PTFE components can enhance your system's performance and durability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance