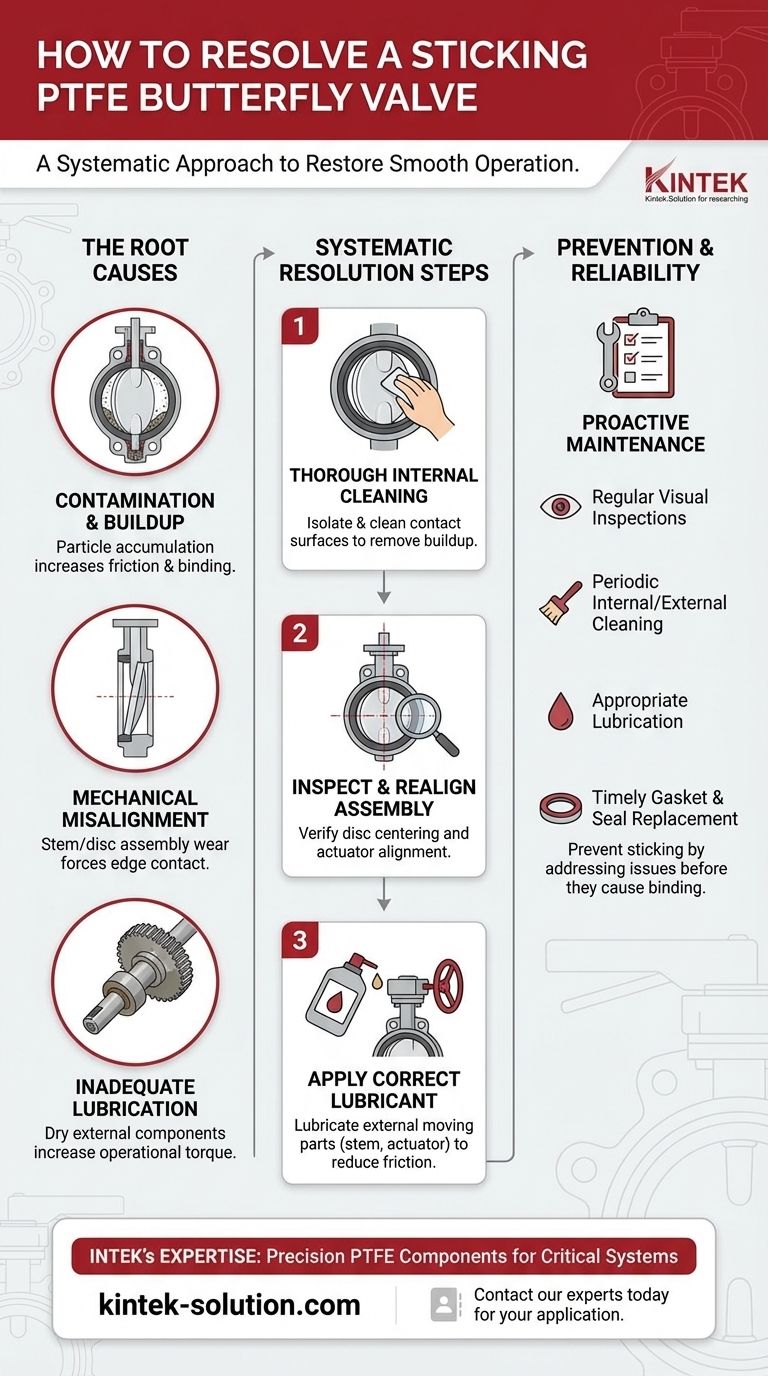

To resolve a sticking or hard-to-operate PTFE butterfly valve, you must systematically address the three most common causes of increased friction. The solution involves a methodical process of cleaning the valve seat and disc, verifying the alignment of the stem and disc assembly, and lubricating the external moving components with a suitable agent.

The core issue behind a sticking PTFE valve is almost always excessive operational torque caused by contamination, mechanical binding, or a lack of lubrication on external components. Addressing these friction points methodically will restore smooth operation.

Diagnosing the Root Cause of Sticking

A PTFE-lined butterfly valve is designed for low-friction operation, thanks to PTFE's natural properties. When operation becomes difficult, it signals an external force or contaminant is interfering with its simple, quick shut-off mechanism.

Contaminant and Media Buildup

The most frequent cause of sticking is the accumulation of process media between the disc and the soft PTFE liner.

Over time, particles, crystallized fluids, or polymers can build up, effectively increasing the diameter of the disc and causing it to bind against the seat when closing or opening.

Mechanical Misalignment

The valve's disc must rotate perfectly centered within the pipe and valve body.

Improper installation, pipe stress, or wear can cause the stem and disc assembly to become misaligned. This forces the edge of the disc to scrape against the PTFE liner instead of compressing it evenly, resulting in high friction and sticking.

Inadequate Lubrication

While the internal PTFE surface is self-lubricating against the disc, the external components are not.

The valve stem, which passes through the packing to the actuator or handwheel, requires lubrication to move freely. Dried-out packing or unlubricated actuator gears are common sources of high operational friction.

A Systematic Approach to Resolution

Follow these steps in order to diagnose and resolve the issue without causing unnecessary downtime or component damage.

Step 1: Thorough Internal Cleaning

Begin with the simplest and most common solution. The valve must be isolated from the system and thoroughly cleaned.

Focus on the contact surfaces: the edge of the circular disc and the entire inner surface of the PTFE seat. Removing any hardened buildup is often sufficient to restore smooth operation.

Step 2: Inspect and Realign the Assembly

If cleaning does not solve the problem, the next step is to inspect for mechanical binding.

With the valve partially open, visually check if the disc is centered within the seat. If it appears off-center, the valve may need to be re-installed, or the actuator may require adjustment to ensure the stem is not under undue side-load.

Step 3: Apply the Correct Lubricant

Finally, address the external friction points.

Apply a lubricant that is compatible with your process environment to the valve stem and any moving parts on the handwheel or actuator. This reduces the torque required to overcome packing friction and operate the valve.

Understanding the Trade-offs and Prevention

While PTFE provides exceptional chemical resistance and a low-friction surface, its softness can be a factor in operational issues. Proactive measures are key to reliability.

The Nature of PTFE Sealing

PTFE butterfly valves achieve a seal by compressing the soft liner with the edge of the disc. This interference fit is what makes them so effective for shutoff.

However, this design also creates a sensitive area where buildup can easily cause binding. It highlights the importance of keeping the valve surfaces clean, especially in services with particulate or high-viscosity media.

The Critical Role of Preventative Maintenance

Sticking is rarely a sudden failure; it is a symptom of developing issues. A simple maintenance schedule is the most effective way to prevent it.

This schedule should include regular visual inspections, periodic internal and external cleaning, appropriate lubrication of stems and actuators, and the timely replacement of gaskets and seals as they wear.

How to Apply This to Your System

Your approach should be dictated by whether you are facing an active problem or planning for future reliability.

- If your primary focus is resolving a current sticking issue: Methodically execute the three-step process of cleaning, checking alignment, and lubricating external components.

- If your primary focus is preventing future operational problems: Implement a preventative maintenance schedule that includes regular inspections and cleaning to manage contamination before it can cause binding.

By understanding the root causes of friction, you can ensure your PTFE valves operate reliably and effectively for their entire service life.

Summary Table:

| Step | Action | Purpose |

|---|---|---|

| 1 | Thorough Internal Cleaning | Remove contaminant buildup between disc and PTFE seat. |

| 2 | Inspect and Realign Assembly | Ensure disc is centered to prevent mechanical binding. |

| 3 | Apply Correct Lubricant | Reduce friction on the external stem and actuator components. |

Is valve downtime impacting your process reliability? KINTEK specializes in precision-manufactured PTFE components, including seals, liners, and custom valve parts for the semiconductor, medical, and laboratory industries. Our expertise ensures your critical fluid systems operate smoothly. Let's discuss a solution for your specific application—contact our experts today!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the installation methods for PTFE slide bearings? Bolting, Welding & Mortar Embedment

- What are some tips for CNC machining Teflon? Master PTFE Machining for Superior Results

- What were the benefits of PTFE wear plates in the die-casting industry case study? Reduce Downtime & Boost Production

- What are the applications of PTFE in the chemical industry? A Guide to Superior Corrosion Resistance

- How do metal bellows compare to PTFE bellows? Choose the Right Material for Your Application

- What industries commonly use Teflon gland packing and why? Unlock Superior Sealing Performance

- How can the creep formation issue in PTFE gaskets be addressed? Ensure a Long-Term, Leak-Free Seal

- What are the common types of fillers used in PTFE compounds? Enhance Performance for Demanding Applications