In the world of heat pressing, a Teflon sheet is a non-stick, heat-resistant cover placed between the hot upper platen of your press and the garment or substrate you are personalizing. It acts as an essential protective barrier, ensuring both your equipment and your projects remain clean, undamaged, and professional.

The core purpose of a Teflon sheet is not just to protect, but to standardize your results. It acts as an insurance policy against common failures like scorching and ink transfer, ensuring consistent quality from the first press to the last.

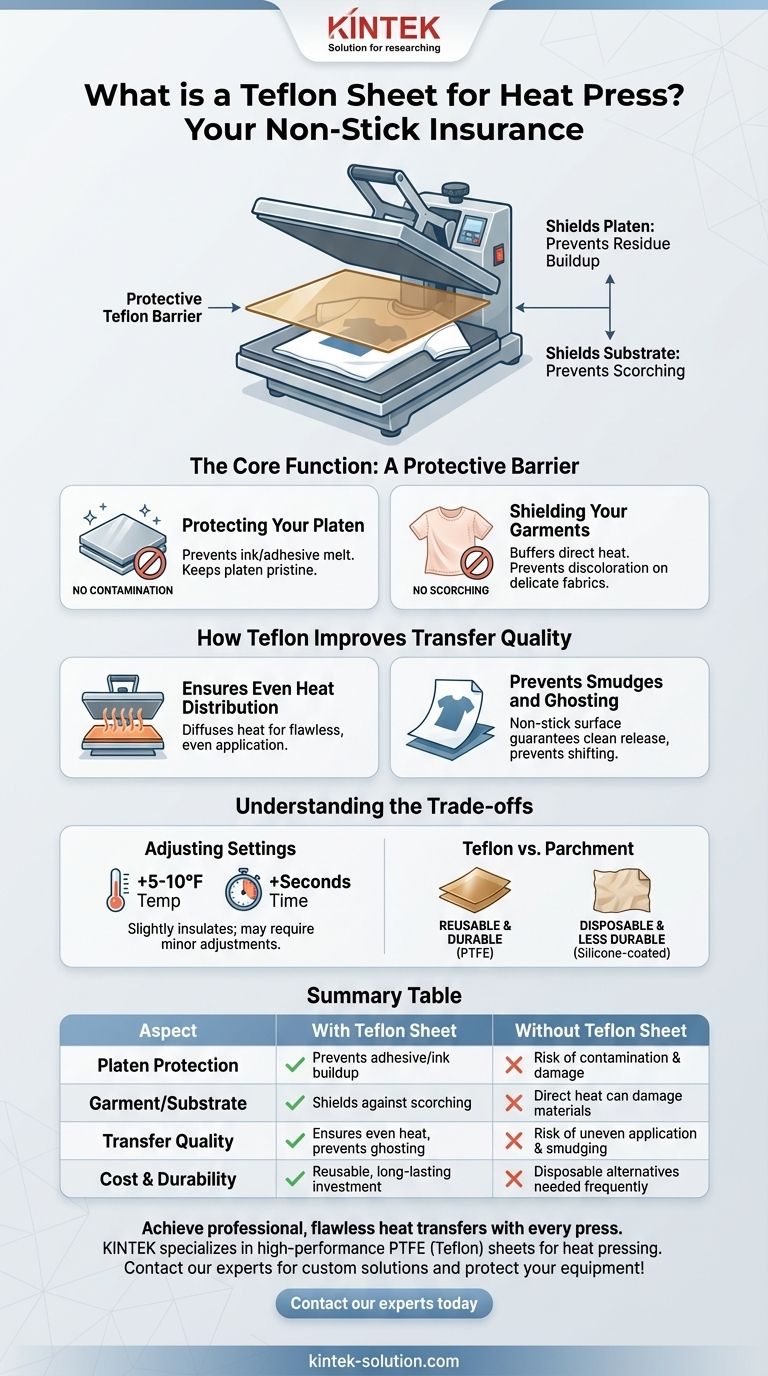

The Core Function: A Protective Barrier

A Teflon sheet’s primary value comes from its ability to shield the two most important components of any heat transfer: the machine itself and the item being printed.

Protecting Your Heat Press Platen

The upper platen of your heat press is a precision-engineered heating element. When transfer paper, vinyl, or ink comes into direct contact, residue can melt onto its surface.

This buildup contaminates the platen, potentially transferring old ink or melted adhesive onto your next project. A Teflon sheet creates a non-stick barrier, preventing this entirely and making cleanup effortless.

Shielding Your Garments and Substrates

Direct, high-temperature contact can be too intense for many materials. The Teflon sheet acts as a buffer against harsh, direct heat.

This is critical for preventing scorching or discoloration, especially on delicate or light-colored fabrics like white polyester. It ensures the heat is just enough for the transfer, not enough to damage the material itself.

How Teflon Improves Transfer Quality

Beyond simple protection, using a Teflon sheet actively contributes to a more professional and reliable transfer process.

Ensuring Even Heat Distribution

The sheet helps to diffuse the heat from the platen more evenly across the surface of the transfer.

This subtle moderation helps prevent hot spots and ensures the entire design receives consistent temperature and pressure, leading to a flawless, even application without faded or under-cured areas.

Preventing Smudges and Ghosting

The signature non-stick surface of Teflon is key. It guarantees that neither the transfer paper nor the garment will stick to the hot platen upon opening the press.

This clean release is crucial for preventing designs from smudging, shifting, or creating a faint "ghost" image as the press lifts away.

Understanding the Trade-offs

While highly beneficial, it's important to understand how a Teflon sheet fits into your workflow. It is not a magic bullet but a tool with specific characteristics.

Is It Always Necessary?

For most applications involving HTV (heat transfer vinyl), sublimation, or plastisol transfers, using a Teflon sheet is a best practice. It minimizes risk with virtually no downside.

However, some specialty transfers may come with their own cover sheets or require direct platen contact. Always defer to the instructions provided by your transfer material manufacturer.

Adjusting Your Press Settings

Because the Teflon sheet adds a thin layer between the heat source and the transfer, it can slightly insulate the process.

You may need to experiment by increasing your temperature by 5-10°F or adding a few seconds to your press time to achieve the same result you would without a sheet. Always test on a scrap piece of material first.

Teflon Sheets vs. Parchment Paper

Parchment paper is a common, lower-cost alternative. However, it is fundamentally different.

Parchment paper is silicone-coated paper that is disposable and less durable. A Teflon (PTFE) sheet is a reusable, long-lasting tool that can withstand hundreds or thousands of presses without degrading.

Making the Right Choice for Your Goal

Your choice of protective cover should align directly with your operational goals.

- If your primary focus is consistency and professional output: A Teflon sheet is a non-negotiable tool for protecting your work and ensuring repeatable quality.

- If your primary focus is protecting your equipment investment: A Teflon sheet is the best way to keep your upper platen pristine and prevent cross-contamination between jobs.

- If you are working with delicate or expensive garments: The anti-scorching benefit of a Teflon sheet makes it an essential piece of insurance.

- If you are in a pinch or on a strict budget: High-quality parchment paper can suffice for short-term use, but understand it will need frequent replacement.

Ultimately, incorporating a Teflon sheet into your workflow is a small step that delivers significant gains in reliability and professionalism.

Summary Table:

| Aspect | With Teflon Sheet | Without Teflon Sheet |

|---|---|---|

| Platen Protection | Prevents adhesive/ink buildup | Risk of contamination and damage |

| Garment/Substrate | Shields against scorching | Direct heat can damage materials |

| Transfer Quality | Ensures even heat, prevents ghosting | Risk of uneven application and smudging |

| Cost & Durability | Reusable, long-lasting investment | Disposable alternatives needed frequently |

Achieve professional, flawless heat transfers with every press. KINTEK specializes in manufacturing high-performance, durable PTFE (Teflon) sheets and components designed for the demands of heat pressing and other specialized industries. Whether you need a standard size or a custom-fabricated solution for high-volume orders, our precision production ensures a perfect non-stick barrier for your projects. Contact our experts today to find the ideal Teflon sheet for your needs and protect your valuable equipment and materials!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why are PTFE-lined butterfly valves resistant to corrosion? The Power of an Inert Barrier

- How does CNC machining contribute to cost-efficiency in PTFE part manufacturing? Achieve Precision and Reduce Waste

- What challenges does the low mechanical strength of PTFE material present? Managing Creep and Cold Flow

- What are the key properties of PTFE washers? Ensure Reliability in Extreme Environments

- What are the advantages of using PTFE Expansion Bellows? Maximize System Integrity & Uptime

- Why are PTFE gaskets considered durable in harsh conditions? Unmatched Chemical & Temperature Resistance

- What modifications can be made to a PTFE seal to handle slight shaft runout? Compensate for Dynamic Movement

- What precautions should be taken during the installation of PTFE gasket seals? Ensure a Perfect, Leak-Free Seal