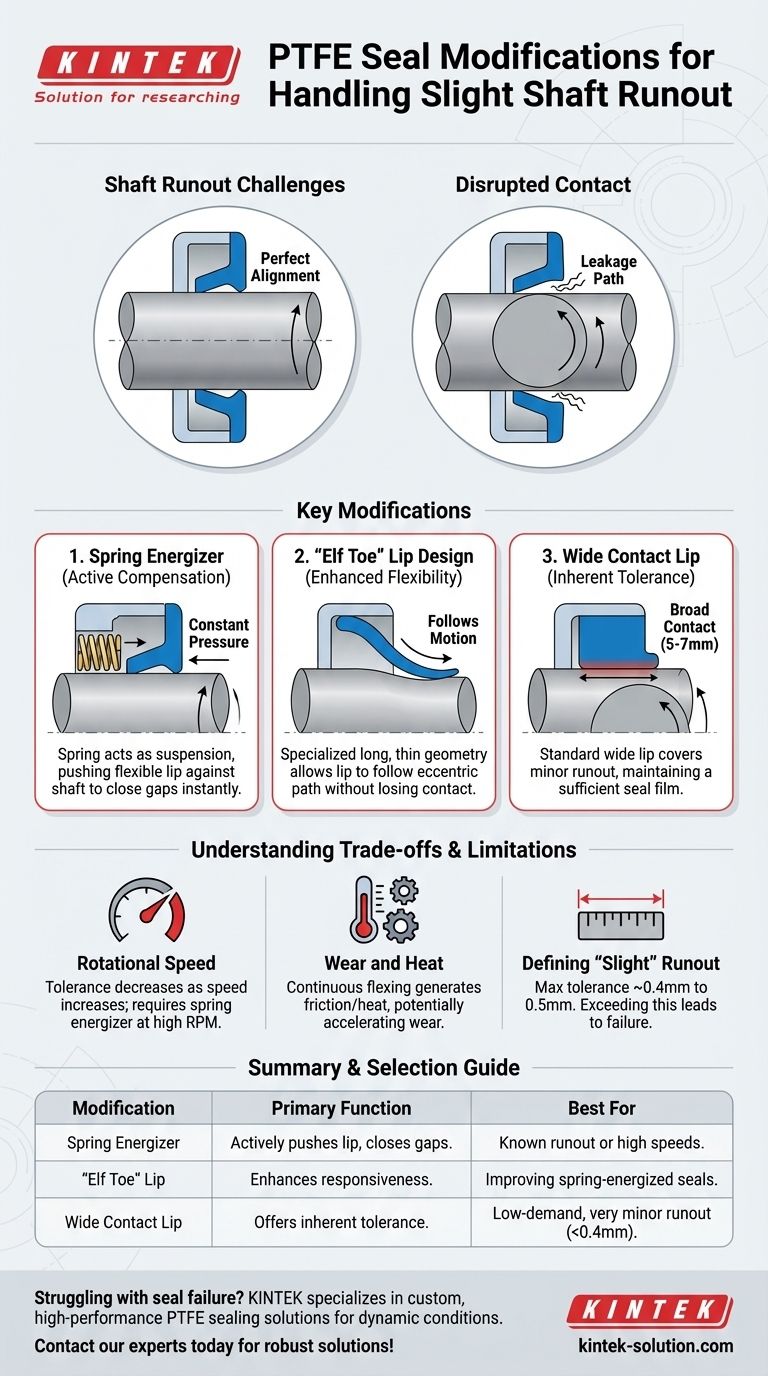

To handle slight shaft runout, a PTFE seal can be modified with a specialized lip geometry, often called an "elf toe" design, to improve flexibility. More commonly, a spring is added behind the seal lip to provide consistent, active pressure against the shaft, ensuring continuous contact despite the eccentric motion.

The core challenge of shaft runout is maintaining consistent contact between the seal lip and the shaft. While PTFE's wide lip design offers some inherent tolerance, adding a spring energizer is the most effective modification for actively compensating for these dynamic imperfections.

Why Shaft Runout Challenges a Seal

The Need for Consistent Contact

A seal's primary function depends on maintaining a precise, unbroken line of contact with the shaft. This contact, under pressure, creates the barrier that prevents leakage.

How Runout Disrupts the Seal

Shaft runout, or eccentric rotation, means the center of the shaft is not perfectly aligned with the center of rotation. As the shaft spins, it creates a gap that rhythmically opens and closes between the seal lip and the shaft surface, providing an escape path for fluids or an entry point for contaminants.

Key Modifications for Handling Runout

Spring Energizing for Active Compensation

The most critical modification is the addition of a spring energizer (often a small metal spring) in a groove behind the PTFE lip.

This spring acts like a suspension system, constantly pushing the flexible lip against the shaft. When runout creates a momentary gap, the spring's force immediately closes it, maintaining the seal.

The "Elf Toe" Lip Design

An "elf toe" refers to a specific lip geometry that is longer, thinner, and more flexible than a standard lip. This enhanced flexibility allows the lip to more easily follow the shaft's eccentric path without losing contact.

This design works in tandem with a spring energizer to maximize the seal's ability to respond to dynamic movement.

The Inherent Advantage of a Wide Lip

Standard PTFE seals often feature a wide contact lip, sometimes 5-7mm wide. This design provides a natural tolerance for minor runout.

Even if the shaft moves eccentrically, a significant portion of the wide lip remains in contact, which is often sufficient to maintain the necessary oil film and prevent leakage in low-demand applications.

Understanding the Trade-offs and Limitations

Defining "Slight" Runout

The tolerance for runout is not infinite and is a critical design constraint. Most modified PTFE seals are designed for runout in the range of 0.4mm to 0.5mm (approximately 0.016 to 0.020 inches).

Exceeding this limit will overwhelm the seal's ability to compensate, leading to inevitable leakage.

The Impact of Rotational Speed

Tolerance for runout decreases as rotational speed increases. At high RPMs, the seal lip has less time to react to the shaft's eccentric movement. A spring-energized design becomes essential in high-speed applications to ensure the lip can keep up.

Increased Wear and Heat

Accommodating runout forces the seal lip to flex continuously. This constant movement generates additional friction and heat, which can accelerate wear and potentially reduce the operational life of the seal compared to an application with a perfectly centered shaft.

Making the Right Choice for Your Application

- If your primary focus is sealing with minimal runout (<0.4mm) at moderate speeds: A standard, non-energized wide-lip PTFE seal may be sufficient and more cost-effective.

- If your primary focus is reliable sealing with known runout or high speeds: A spring-energized PTFE seal is the definitive choice to ensure consistent contact and prevent leakage.

- If your primary focus is performance in harsh environments (chemicals, temperature): PTFE is an excellent material choice, but you must still select a spring-energized design if significant runout is present.

By understanding these design principles, you can select a sealing solution that is robust, reliable, and perfectly matched to your equipment's specific dynamic conditions.

Summary Table:

| Modification | Primary Function | Best For |

|---|---|---|

| Spring Energizer | Actively pushes seal lip against shaft to close gaps caused by runout. | Applications with known runout or high rotational speeds. |

| 'Elf Toe' Lip Design | Provides a longer, more flexible lip to better follow the eccentric shaft path. | Enhancing the responsiveness of a spring-energized seal. |

| Wide Contact Lip | Offers inherent tolerance via a broad (5-7mm) contact area. | Low-demand applications with very minor runout (<0.4mm). |

Struggling with seal failure due to shaft runout? KINTEK specializes in designing and manufacturing high-performance, custom PTFE seals—including spring-energized and specialized lip geometries—precisely engineered to handle dynamic conditions in semiconductor, medical, laboratory, and industrial equipment. Let our experts provide a robust sealing solution that extends component life and prevents leakage. Contact our engineering team today to discuss your application requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications