At its core, a PTFE-lined butterfly valve resists corrosion because it creates an impenetrable barrier. The chemically inert Polytetrafluoroethylene (PTFE) lining completely isolates the valve's structural metal body from the corrosive fluid passing through it. This design leverages the exceptional chemical resistance of PTFE without requiring the entire valve to be constructed from expensive, exotic alloys.

The effectiveness of a PTFE-lined valve is not just due to the material itself, but to the design philosophy: use a standard, cost-effective metal body for structural integrity, and line every wetted surface with inert PTFE. This provides the corrosion resistance of a high-end alloy at a fraction of the cost.

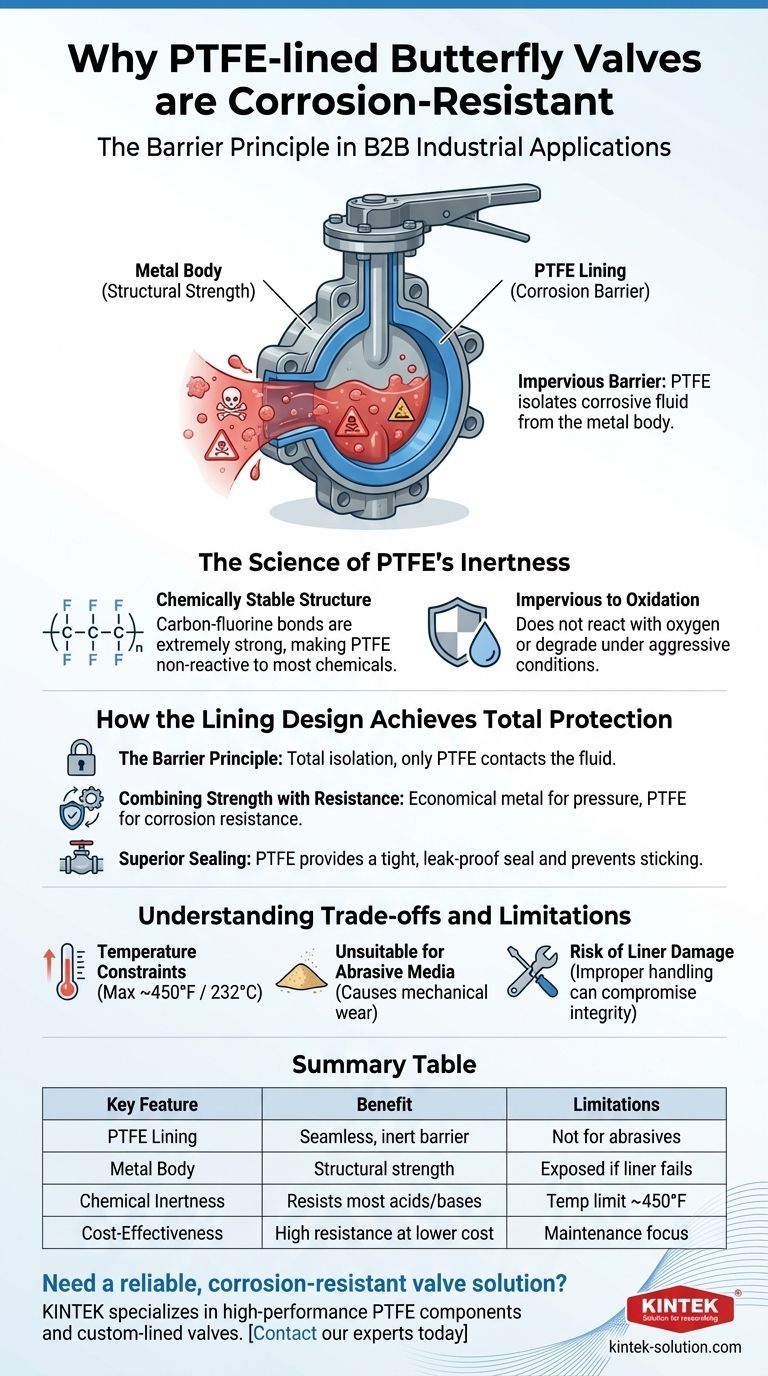

The Science of PTFE's Chemical Inertness

To understand why this valve design is so effective, we must first look at the unique molecular properties of PTFE, commonly known by the brand name Teflon.

A Chemically Stable Structure

PTFE's molecular structure is composed of a chain of carbon atoms completely shielded by fluorine atoms. This carbon-fluorine bond is one of the strongest in organic chemistry.

This powerful bond makes the material extremely non-reactive. It is impervious to attack from the vast majority of industrial chemicals.

Impervious to Oxidation and Attack

Unlike metals, PTFE does not react with oxygen and is not susceptible to oxidation, the process that causes rust and other forms of corrosion.

It remains stable and does not degrade or lose its plasticity even with continuous exposure to aggressive acids, caustics, and solvents.

How the Lining Design Achieves Total Protection

The material's properties are only half the story. The true innovation lies in how it is applied within the butterfly valve's construction.

The Barrier Principle

The fundamental concept is total isolation. The PTFE liner is molded to fit the interior of the valve body, creating a continuous, seamless surface.

This ensures that the fluid medium—no matter how corrosive—only ever comes into contact with the PTFE. The valve's metal body, which provides pressure containment and structural support, is never exposed.

Combining Strength with Resistance

This design allows for the best of both worlds. A robust and economical material like cast iron or carbon steel can be used for the valve body.

The chemically vulnerable metal provides the mechanical strength, while the relatively soft PTFE provides the chemical resistance.

Superior Sealing Performance

The PTFE liner, often backed by a flexible elastomer like rubber, also serves as the valve's seat.

This creates a tight, leak-proof seal when the valve disc closes. The excellent wetting and non-stick characteristics of PTFE further enhance sealing integrity and prevent media from sticking to valve internals.

Understanding the Trade-offs and Limitations

While highly effective, PTFE-lined valves are not a universal solution. An objective assessment requires understanding their operational limits.

Temperature Constraints

PTFE has a distinct temperature range. While excellent for many processes, it typically has a maximum service temperature of around 450°F (232°C). Beyond this point, the material can begin to degrade.

Unsuitability for Abrasive Media

PTFE is a relatively soft material. It is an excellent choice for clean, corrosive liquids and gases but can be quickly eroded by fluids containing abrasive particles or slurries. This mechanical wear can compromise the liner and expose the metal body.

Risk of Liner Damage

The integrity of the liner is paramount. Improper installation, over-torquing of bolts, or significant mechanical stress can damage the PTFE lining. Any scratch or puncture creates a direct path for corrosive fluid to attack the valve body, leading to rapid failure.

Making the Right Choice for Your Application

Selecting the correct valve requires matching its capabilities to your specific operational goal.

- If your primary focus is handling highly aggressive chemicals: A PTFE-lined valve offers near-universal chemical compatibility, making it a reliable and safe default choice for acids, bases, and solvents.

- If your primary focus is balancing performance and budget: This design provides the corrosion protection of exotic alloys like Hastelloy without the associated high material cost, offering an exceptional value proposition.

- If your primary focus is process purity or non-stick surfaces: The inert, low-friction surface of PTFE prevents media contamination and residue buildup, making it ideal for food, pharmaceutical, or high-purity chemical applications.

Ultimately, a PTFE-lined valve is an engineered solution that intelligently separates the functions of structural strength and chemical resistance to deliver exceptional performance in corrosive environments.

Summary Table:

| Key Feature | Benefit |

|---|---|

| PTFE Lining | Creates a seamless, inert barrier against corrosive fluids. |

| Metal Body | Provides structural strength and pressure containment. |

| Chemical Inertness | Resists attack from most acids, bases, and solvents. |

| Cost-Effectiveness | Offers corrosion resistance of exotic alloys at a lower cost. |

| Limitations | Temperature limit (~450°F); not suitable for abrasive media. |

Need a reliable, corrosion-resistant valve solution for your application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom-lined valves, seals, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a solution tailored to handle your specific corrosive media safely and cost-effectively.

Contact our experts today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry