At its core, CNC machining drives significant cost-efficiency in PTFE part manufacturing through unparalleled precision. This automated accuracy drastically reduces material waste from errors, eliminates the high cost of rework, and ensures components function correctly the first time, preventing expensive operational failures.

While PTFE's softness makes it easy to cut, its tendency to expand with heat and deform under pressure makes it difficult to machine accurately. CNC machining's true value lies in its precise control over these variables, turning a challenging material into a reliable and cost-effective component.

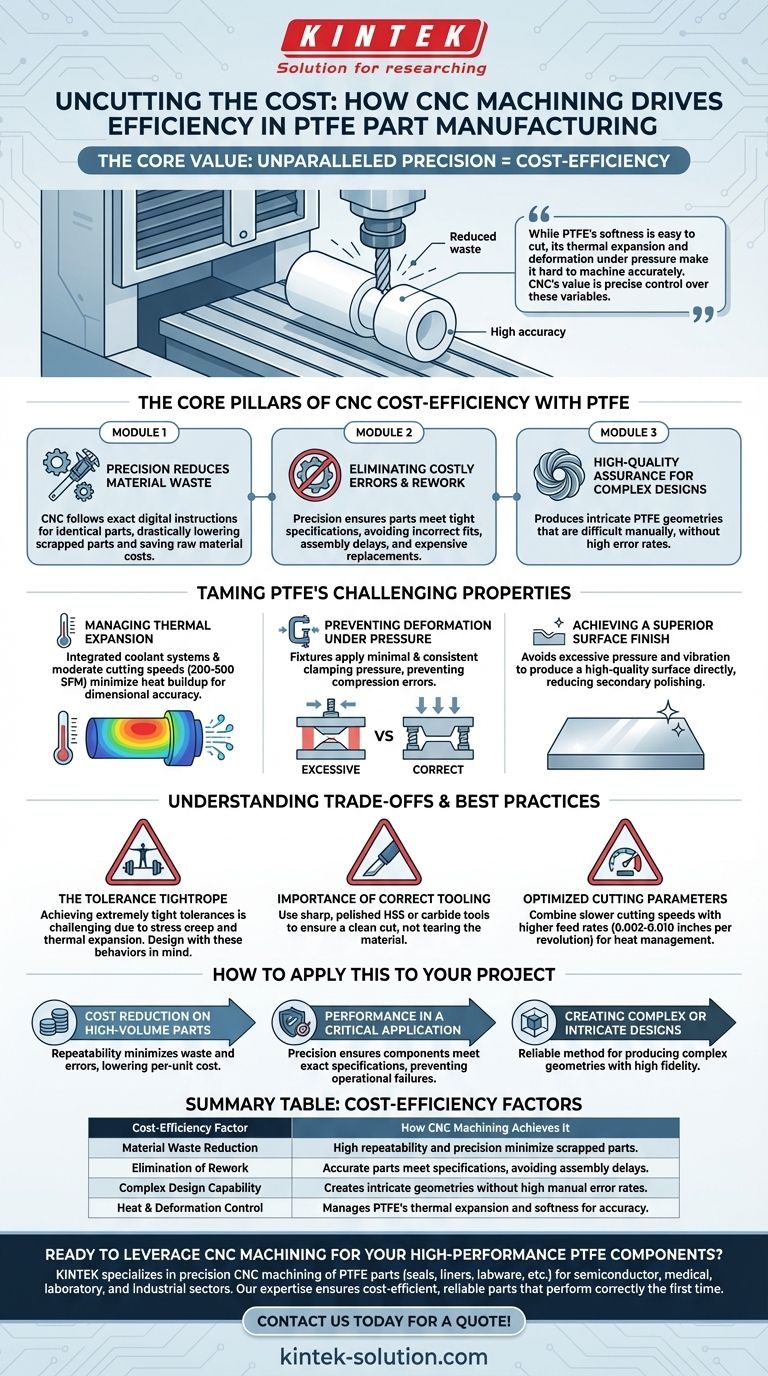

The Core Pillars of CNC Cost-Efficiency with PTFE

Computer Numerical Control (CNC) machining introduces a level of automation and repeatability that directly translates into savings, especially when working with a material as unique as Polytetrafluoroethylene (PTFE).

Precision that Reduces Material Waste

CNC machines follow exact digital instructions, producing identical parts with minimal deviation. This high repeatability means far fewer scrapped parts compared to manual methods, directly saving on the cost of raw PTFE material.

Eliminating Costly Errors and Rework

The precision of CNC ensures that parts meet tight specifications. This avoids the common pitfalls of incorrect fits, which can lead to expensive assembly delays, the need for part replacements, or inefficient system operations.

High-Quality Assurance for Complex Designs

CNC technology can produce intricate PTFE geometries that are difficult or impossible to create manually. It achieves this without the high error rates and material waste that would typically accompany such complex manual work.

Taming PTFE's Challenging Properties

The primary cost driver in PTFE manufacturing isn't just cutting the material—it's controlling its inherent properties. CNC machining provides the necessary control to overcome these challenges efficiently.

Managing Thermal Expansion

PTFE has a high coefficient of thermal expansion, meaning it expands and contracts significantly with temperature changes. CNC systems manage this by using integrated coolant systems and maintaining moderate cutting speeds (200 to 500 surface feet per minute) to minimize heat buildup and ensure dimensional accuracy.

Preventing Deformation Under Pressure

As a soft material, PTFE can easily be compressed or deformed by excessive clamping pressure, leading to inaccurate final dimensions. CNC machining allows for fixtures that apply minimal and consistent clamping pressure, preventing this common source of error.

Achieving a Superior Surface Finish

To function correctly, many PTFE parts require a smooth surface. CNC programming avoids the excessive pressure and tool vibration that can mar the material's finish, producing a high-quality surface directly from the machine and reducing the need for secondary polishing.

Understanding the Trade-offs and Best Practices

While highly efficient, achieving success with CNC-machined PTFE requires acknowledging its limitations and adhering to best practices. Misunderstanding the material can quickly erode any potential cost savings.

The Tolerance Tightrope

Despite CNC's precision, achieving extremely tight tolerances with PTFE remains a challenge due to its properties of stress creep (a tendency to slowly deform under load) and thermal expansion. Applications must be designed with these material behaviors in mind.

The Importance of Correct Tooling

Using the wrong tools is a common and costly mistake. For PTFE, tools must be extremely sharp and well-polished, preferably made from high-speed steel (HSS) or carbide, to ensure a clean cut rather than tearing the material.

Optimized Cutting Parameters are Non-Negotiable

The key to machining PTFE is heat management. This is typically achieved with a combination of slower cutting speeds and higher feed rates (0.002 to 0.010 inches per revolution). This approach minimizes the time the cutting tool generates friction in one spot, preventing overheating.

How to Apply This to Your Project

Your specific goal will determine how you leverage the cost-efficiency of CNC-machined PTFE.

- If your primary focus is cost reduction on high-volume parts: CNC machining provides the essential repeatability to minimize waste and errors, directly lowering your per-unit cost.

- If your primary focus is performance in a critical application: The precision of CNC ensures your PTFE components meet exact specifications, preventing costly operational failures and frequent replacements.

- If your primary focus is creating complex or intricate designs: CNC machining is the most reliable method for producing complex PTFE geometries with high fidelity, turning challenging designs into functional parts.

By mastering the unique challenges of PTFE, CNC machining transforms this versatile material into a reliably precise and cost-effective solution.

Summary Table:

| Cost-Efficiency Factor | How CNC Machining Achieves It |

|---|---|

| Material Waste Reduction | High repeatability and precision minimize scrapped parts. |

| Elimination of Rework | Accurate parts meet specifications, avoiding assembly delays. |

| Complex Design Capability | Creates intricate geometries without high manual error rates. |

| Heat & Deformation Control | Manages PTFE's thermal expansion and softness for accuracy. |

Ready to leverage CNC machining for your high-performance PTFE components?

KINTEK specializes in precision CNC machining of PTFE parts (seals, liners, labware, etc.) for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in taming PTFE's challenging properties ensures you get cost-efficient, reliable parts—from prototypes to high-volume production—that perform correctly the first time.

Contact us today to discuss your project and receive a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the three primary application areas for PTFE O-rings? Master Sealing in Harsh Environments

- Why is the low friction coefficient of PTFE gaskets important? Key to Durability and Efficiency

- What are the advantages of spring-loaded lift check valves? Achieve Reliable, Non-Slam Backflow Prevention

- What are the advantages of PTFE-lined butterfly valves over lined ball valves in pharmaceutical applications? Achieve Superior Sterility and Cleanability

- Why are PTFE lined pipes considered essential for certain industries? Unmatched Corrosion Resistance & Purity

- Why can PTFE ball valves be used in corrosive media? Unmatched Chemical Resistance for Safe Fluid Control

- How does Teflon benefit the fabric and carpet industry? Achieve Superior Stain Resistance

- What does the leakage rate indicate about PTFE gaskets? Understanding the Sealing Performance Trade-off