In essence, a lip seal is a simple yet highly effective component used to prevent fluid leakage and contaminant entry around a rotating shaft. It achieves this by using a flexible, precisely shaped "lip," typically made of an elastomeric material, which maintains light, continuous contact with the shaft's surface. This contact is engineered to be just firm enough to contain lubricant while allowing a microscopic film to form, which is critical to its function.

The core principle of a lip seal is not brute force, but finesse. It relies on creating a stable, self-lubricating hydrodynamic film between the seal lip and the rotating shaft, which acts as the true dynamic barrier.

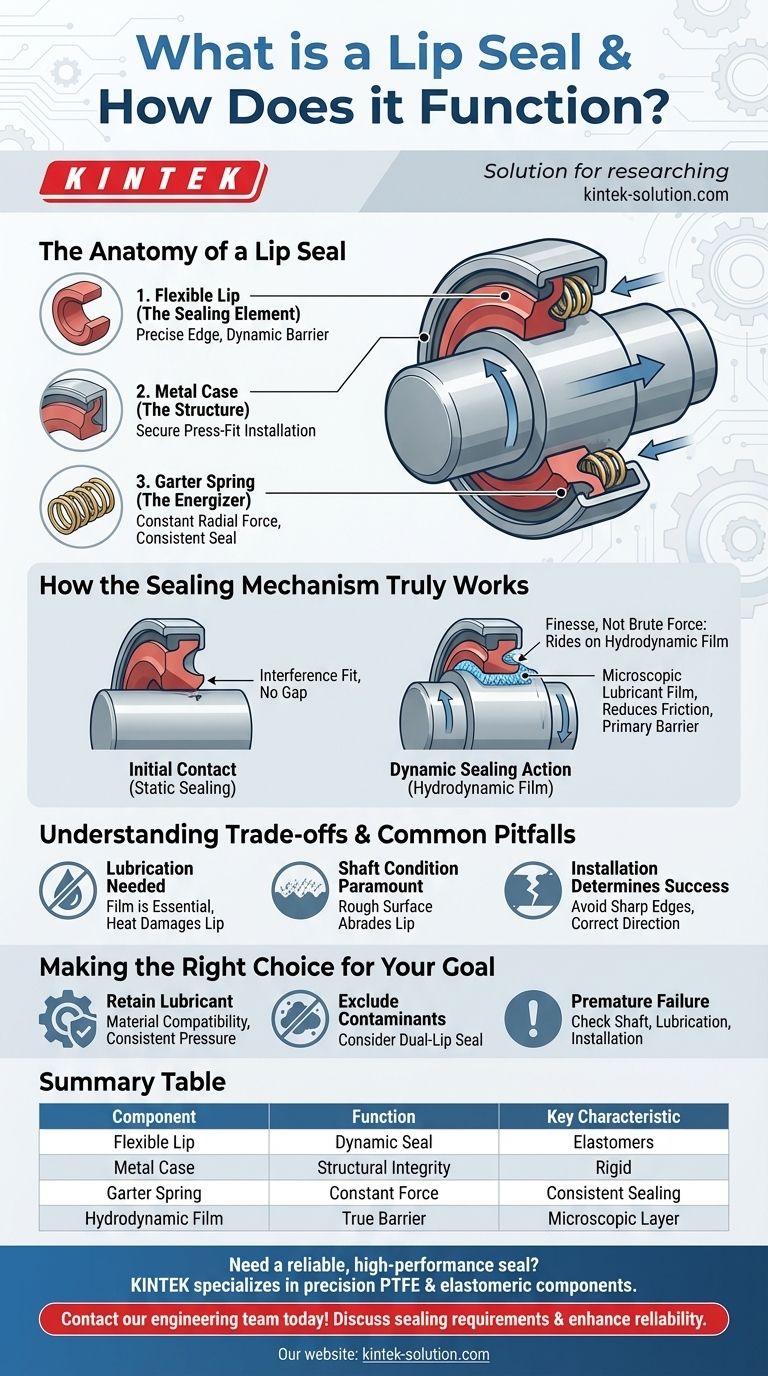

The Anatomy of a Lip Seal

To understand how a lip seal functions, we must first examine its key components. While it appears to be a simple ring, its design is a careful balance of materials and geometry.

The Flexible Lip (The Sealing Element)

This is the most critical part of the seal. It is a precisely molded, flexible edge that makes direct contact with the shaft. Its angled shape is designed to create a defined contact point and respond to internal fluid pressure.

The lip is made from various elastomeric materials, such as Nitrile, Viton, or Silicone, chosen based on the fluid being sealed, operating temperature, and rotational speed.

The Metal Case (The Structure)

The soft, flexible lip is bonded to a rigid metal case. This case provides structural integrity to the entire seal.

Its primary function is to allow for a secure press-fit installation into a stationary housing, ensuring the seal remains fixed while the shaft rotates within it.

The Garter Spring (The Energizer)

Encircling the back of the flexible lip is a small coil spring known as the garter spring. This is a crucial component for long-term performance.

The spring provides a constant, uniform radial force, pressing the lip against the shaft. This ensures a consistent seal even as the lip wears over time or as materials expand and contract with temperature changes.

How the Sealing Mechanism Truly Works

The sealing action is a dynamic process that changes from a stationary to a rotating state. It's a combination of mechanical pressure and fluid dynamics.

The Initial Contact (Static Sealing)

When installed, the inner diameter of the seal lip is slightly smaller than the outer diameter of the shaft. This interference fit creates the initial, static seal when the shaft is not moving.

The garter spring applies a light, constant pressure, ensuring there is no gap for fluid to escape.

The Dynamic Sealing Action (Hydrodynamic Film)

This is the key to the seal's function and longevity. As the shaft begins to rotate, it pulls a microscopic film of the lubricant (the fluid being sealed) underneath the lip.

This extremely thin layer, known as the hydrodynamic film, is what the seal lip actually "rides" on. The film serves two vital purposes: it drastically reduces friction and heat, and it acts as the primary barrier preventing leakage. The seal's effectiveness depends on maintaining this stable, microns-thin film.

Understanding the Trade-offs and Common Pitfalls

While highly effective, lip seals are not infallible. Their performance is directly tied to the system they are part of, and failure often points to an external issue.

The Critical Need for Lubrication

A lip seal run without lubrication will fail very quickly. The hydrodynamic film is essential. Without it, friction rapidly generates intense heat, which can harden, crack, or even melt the elastomeric lip material.

Shaft Condition is Paramount

The surface of the shaft is the other half of the sealing system. A shaft with scratches, rust, or a rough finish will act like a file, quickly abrading the seal lip and creating a leak path. A smooth, polished surface is required for a long seal life.

Installation Determines Success

A common cause of immediate failure is improper installation. Forcing the seal over sharp edges or keyways can easily cut or nick the lip. Furthermore, installing the seal backward will render it ineffective, as the lip is designed to work with pressure from a specific direction.

Making the Right Choice for Your Goal

Selecting and implementing a lip seal requires understanding its role within the larger mechanical system.

- If your primary focus is retaining lubricant: Ensure the seal material is chemically compatible with the lubricant and that the garter spring provides consistent pressure to maintain a stable hydrodynamic film.

- If your primary focus is excluding contaminants: Consider a dual-lip seal. This design features a primary lip for retaining lubricant and a secondary, non-spring-loaded "excluder" lip that faces outward to block dust and debris.

- If you are experiencing premature failure: Immediately investigate the system's three key variables: the shaft surface finish, the presence of adequate lubrication, and the installation procedure.

By understanding these core principles, you can ensure the lip seal functions as a reliable and integral component of your mechanical design.

Summary Table:

| Component | Function | Key Characteristic |

|---|---|---|

| Flexible Lip | Creates the dynamic seal against the shaft | Made from elastomers like Nitrile or Viton |

| Metal Case | Provides structural integrity for press-fit installation | Rigid, typically steel |

| Garter Spring | Applies constant radial force to the lip | Ensures consistent sealing pressure |

| Hydrodynamic Film | The true barrier; reduces friction and wear | Microscopic layer of lubricant |

Need a reliable, high-performance seal for your application?

KINTEK specializes in manufacturing precision PTFE and elastomeric components, including custom lip seals, for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a standard solution or a custom fabrication from prototype to high-volume production, our expertise ensures a perfect fit and lasting performance.

Contact our engineering team today to discuss your sealing requirements and discover how we can enhance your design's reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What role does chemical stability play in the performance of Teflon gland fillers? Ensure Long-Term Reliability in Harsh Environments

- What machining parameters should be adjusted when working with Teflon? Optimize for Precision & Safety

- How is PTFE used in ball valves and Y strainers? Essential for Leak-Proof Seals & Chemical Resistance

- What medical applications benefit from extruded PTFE rods? Precision Components for Surgical & Diagnostic Devices

- What are the common applications of expanded PTFE? Unlock High-Performance Sealing, Filtration & Medical Solutions

- What are the key takeaways regarding filled PTFE? Enhance Performance with Engineered PTFE Composites

- What advantages do custom PTFE parts offer for industrial efficiency? Boost Uptime & Cut Costs

- How do PTFE Liners contribute to patient safety? Ensuring Biocompatibility and Minimizing Trauma