To machine Teflon (PTFE) effectively, you must primarily adjust cutting speeds, feed rates, and depth of cut. The central goal of these adjustments is to minimize heat generation and physical pressure, as Teflon's unique properties make it highly susceptible to thermal expansion and deformation.

The core challenge of machining Teflon is not material hardness, but material stability. Success depends entirely on managing its softness, high thermal expansion, and low friction by employing sharp tools, consistent cooling, and light cutting forces to avoid heat buildup and part deformation.

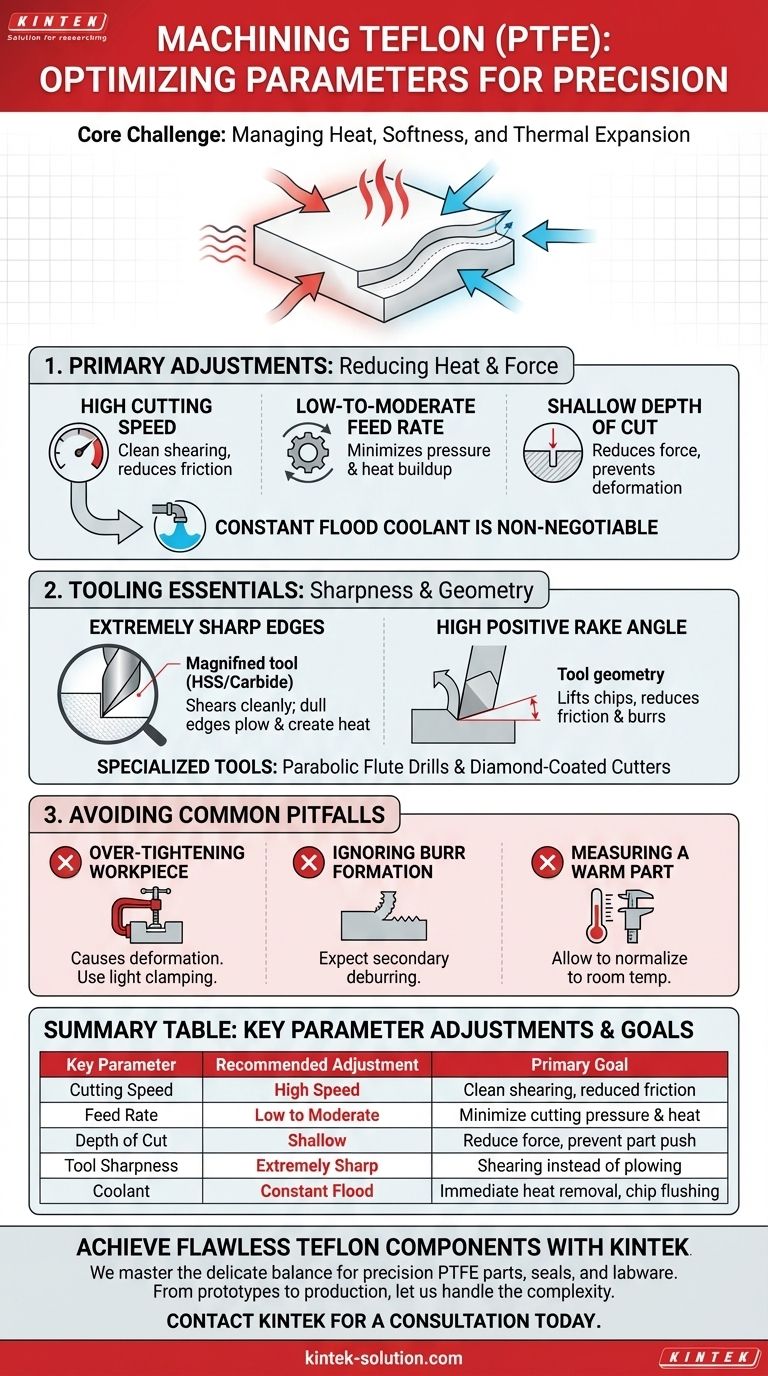

The Core Challenge: Managing Heat and Softness

Before adjusting any parameters, you must understand the properties that make Teflon unique. Its challenges are not related to strength but to its inherent instability under typical machining forces.

High Thermal Expansion

Teflon has a very high coefficient of thermal expansion. Even a small amount of heat generated from friction during cutting will cause the material to expand significantly, making it impossible to hold tight tolerances.

Material Softness and Creep

PTFE is an extremely soft material. This softness means it can easily deform under clamping pressure or from the force of a dull cutting tool. It is also subject to stress creep, where the material slowly deforms over time when held under pressure, further complicating dimensional accuracy.

Low Friction and Workholding

The famously low coefficient of friction makes Teflon slippery and difficult to hold securely in a vise or chuck. The natural instinct is to clamp it tighter, but this leads directly to part deformation due to the material's softness.

Risk of Toxic Gas Release

Safety is a critical parameter. If Teflon is heated above 250°C (482°F), it begins to decompose and can release toxic gases. Proper cooling and ventilation are not just for part quality; they are essential safety measures.

Optimizing Your Machining Parameters

Your primary adjustments should all serve the goal of reducing heat and physical force on the workpiece. This often feels counterintuitive compared to machining metals.

Adjusting Cutting Speeds and Feeds

The general rule is to use high cutting speeds combined with a low-to-moderate feed rate. A high surface speed allows a sharp tool to shear the material cleanly, while a low feed rate reduces the cutting pressure and minimizes friction and heat buildup.

Controlling Depth of Cut

Always use a shallow depth of cut. Taking light passes reduces the cutting forces, prevents the tool from "pushing" the material instead of cutting it, and generates significantly less heat per pass.

The Critical Role of Coolant

A constant flood of coolant is non-negotiable. Coolant serves two primary functions: it immediately removes any heat generated at the cutting edge, and it helps flush away the soft, stringy chips that can wrap around the tool and workpiece.

Selecting the Right Tooling is a Key Parameter

The type and condition of your tooling are as important as the speeds and feeds you set.

The Necessity of Extremely Sharp Edges

Your cutting tools must be as sharp as possible. High-speed steel (HSS) or carbide tools are both effective, but the sharpness of the edge is the most important factor. A sharp edge cleanly shears the material, while a dull edge will plow through it, generating immense friction and deforming the part.

Using Positive Rake Angles

Tools with a high positive rake angle and significant relief are ideal. This geometry helps lift the chip up and away from the workpiece, reducing friction, heat, and the likelihood of burrs forming on the finished edge.

Considering Specialized Tools

For operations like drilling, standard drills are often ineffective. Parabolic flute drills are far better at clearing chips. For the absolute best surface finish and tool life, specialized diamond-coated cutters offer superior performance.

Understanding the Trade-offs and Pitfalls

Machining Teflon successfully requires avoiding common mistakes that stem from treating it like a metal or a harder plastic.

Pitfall: Over-tightening the Workpiece

The most common mistake is clamping the part too tightly, which crushes it and ruins dimensional accuracy. Use fixtures that distribute clamping force over a large area or a soft-jaw setup to hold the material securely without deformation.

Pitfall: Ignoring Burr Formation

Due to its softness, Teflon is highly prone to burrs. Expect to perform a secondary deburring operation. Using an extremely sharp tool with a high rake angle is the best way to minimize this, but it rarely eliminates it completely.

Pitfall: Measuring a Warm Part

Never take a final measurement when the part is still warm from machining. Because of its high thermal expansion, you must allow the component to cool and normalize to room temperature before taking critical measurements or making a final finishing pass.

Making the Right Adjustments for Your Goal

Your specific adjustments should be guided by your primary objective for the finished part.

- If your primary focus is dimensional accuracy: Prioritize aggressive cooling and allow the part to fully normalize to ambient temperature before making any final cuts or measurements.

- If your primary focus is a high-quality surface finish: Use extremely sharp, high-positive-rake tools with a low feed rate to ensure a clean shearing action rather than pushing the material.

- If your primary focus is safety: Ensure excellent ventilation and a constant flow of coolant to keep temperatures well below the 250°C decomposition point at all times.

By respecting Teflon's unique properties and prioritizing the reduction of heat and pressure, you can achieve precise and repeatable results.

Summary Table:

| Key Parameter | Recommended Adjustment | Primary Goal |

|---|---|---|

| Cutting Speed | High Speed | Clean shearing, reduced friction |

| Feed Rate | Low to Moderate | Minimize cutting pressure & heat |

| Depth of Cut | Shallow | Reduce force and prevent part push |

| Tool Sharpness | Extremely Sharp | Shearing instead of plowing material |

| Coolant | Constant Flood | Immediate heat removal and chip flushing |

Achieve Flawless Teflon Components with KINTEK

Machining Teflon (PTFE) to precise specifications requires expertise and specialized tooling. KINTEK manufactures high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, and laboratory industries. We master the delicate balance of parameters to deliver components free from deformation, with superior surface finishes, and tight tolerances.

Let us handle the complexity for you. From prototypes to high-volume production, our custom fabrication service ensures your PTFE parts meet your exact requirements.

Contact KINTEK today for a consultation and quote on your next project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What types of additives can be used with PTFE bushings? Enhance Performance for Demanding Applications

- In what ways are extruded PTFE rods utilized in aerospace and automotive industries? Enhancing Performance in Extreme Conditions

- What are the benefits of graphite-filled PTFE? Superior Self-Lubrication for Demanding Seals & Bearings

- Why are PTFE fasteners used in applications requiring electrical insulation? Ensure Reliable, Non-Conductive Performance

- How do PTFE O-rings differ from rubber O-rings in terms of compliance? Understanding Rigidity vs. Elasticity

- Are PTFE gaskets compliant with FDA standards? Ensure Safety in Food, Pharma & Medical Applications

- How do modified PTFE gaskets differ from pure PTFE gaskets? A Guide to Material Selection

- What are some future trends in the application of PTFE bars in the chemical industry? Engineering for Extreme Performance