In fluid control systems, PTFE is the critical material used for seats in ball valves and seals in Y strainers. Its primary functions are to create a reliable, leak-proof seal and to ensure smooth, low-effort operation of the valve mechanism, even when exposed to aggressive chemicals or wide temperature fluctuations.

The selection of PTFE is not arbitrary; it is a strategic engineering choice. Its unique combination of chemical inertness, low friction, and material stability makes it the enabling component that guarantees the performance and longevity of valves and strainers in demanding industrial environments.

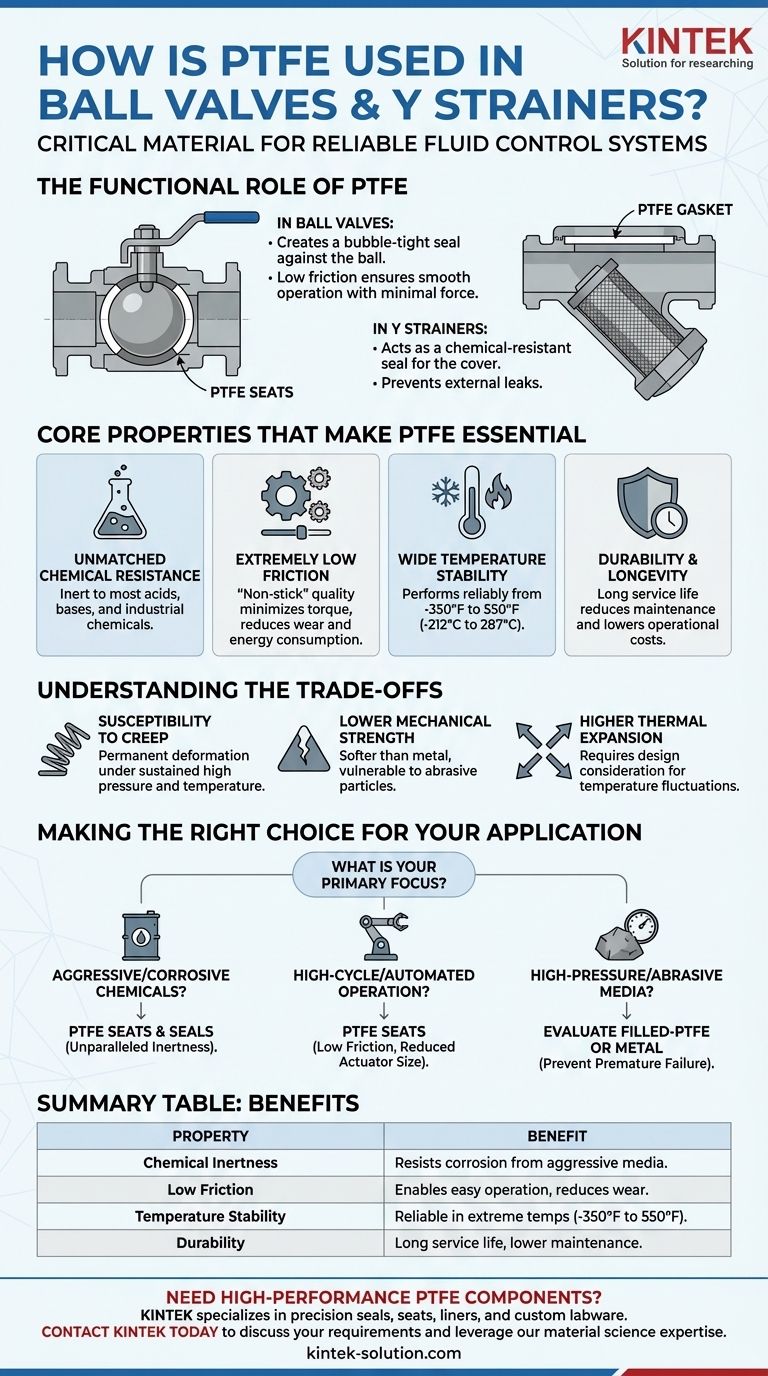

The Functional Role of PTFE in System Components

PTFE's application is highly specific to the mechanical requirements of each device. Its properties are leveraged to solve distinct challenges in ball valves and Y strainers.

In Ball Valves: The Seat Material

A ball valve controls flow with a rotating ball that has a hole through it. The PTFE seats are two rings that press against this ball.

PTFE is essential here for two reasons. First, its malleability allows it to deform slightly, creating a bubble-tight seal against the smooth metal ball. Second, its exceptionally low coefficient of friction ensures the ball can be turned with minimal force, reducing wear and the power required for automated actuators.

In Y Strainers: The Sealing Gasket

A Y strainer protects downstream equipment by filtering out solid particles from a fluid. It has a removable cap or cover to allow for cleaning the internal screen.

PTFE is used for the gasket or seal for this cover. Its role is to prevent external leaks. The material's chemical resistance is paramount, ensuring the seal maintains its integrity even when handling corrosive process media like acids or solvents.

The Core Properties That Make PTFE Essential

The widespread use of PTFE in these components is not accidental. It stems from a set of intrinsic material properties that are almost perfectly suited for the task of industrial sealing.

Unmatched Chemical Resistance

PTFE is almost entirely chemically inert. It will not react with or degrade when exposed to the vast majority of industrial chemicals, acids, and bases. This is why PTFE-lined valves are the standard for highly corrosive applications.

Extremely Low Friction

Often known by the brand name Teflon, PTFE has one of the lowest friction coefficients of any solid. This "non-stick" quality is vital in ball valves, as it minimizes the torque needed to open or close the valve, leading to reduced wear and lower energy consumption over the component's life.

Wide Temperature Stability

PTFE performs reliably across an exceptionally broad temperature range, typically from -350°F to 550°F (-212°C to 287°C). This allows a single valve or strainer specification to be used in systems that experience significant temperature swings without compromising sealing performance.

Durability and Longevity

The combination of chemical, thermal, and wear resistance gives PTFE components a very long service life. This reduces maintenance frequency, lowers operational costs, and increases the overall reliability of the entire fluid system.

Understanding the Trade-offs

While PTFE is an exceptional material, no engineering choice is without its limitations. Acknowledging these is critical for proper application.

Susceptibility to Creep

Under sustained high pressure and temperature, PTFE can be prone to "creep," a slow, permanent deformation. In critical sealing applications, this must be managed through proper valve design or by using filled grades of PTFE that incorporate other materials (like glass or carbon) to improve rigidity.

Lower Mechanical Strength

Compared to metals, PTFE is a soft material. It can be damaged by abrasive particles (like sand or metal shavings) in the fluid stream, which can score the seat and compromise the seal. In such services, a different seat material or upstream filtration may be required.

Higher Thermal Expansion

PTFE expands and contracts with temperature changes more than metals do. Valve designers must account for this differential expansion to ensure that the seal remains tight across the entire intended operating temperature range.

Making the Right Choice for Your Application

Selecting the right valve or strainer component requires matching the material to the operational demands of the system.

- If your primary focus is handling aggressive or corrosive chemicals: PTFE is almost always the correct choice for seats and seals due to its unparalleled chemical inertness.

- If your primary focus is high-cycle or automated operation: The low-friction nature of PTFE seats is essential for reducing actuator size, minimizing energy use, and ensuring a long operational life.

- If your primary focus is high-pressure service or abrasive media: You should evaluate if standard PTFE is sufficient or if a filled-PTFE or a more rigid material like metal is necessary to prevent premature failure.

Ultimately, understanding the properties of PTFE allows you to leverage its strengths for creating exceptionally reliable and durable fluid control systems.

Summary Table:

| Property | Benefit in Ball Valves & Y Strainers |

|---|---|

| Chemical Inertness | Resists corrosion from acids, solvents, and aggressive media. |

| Low Friction | Enables easy valve operation and reduces actuator wear. |

| Temperature Stability | Performs reliably from -350°F to 550°F (-212°C to 287°C). |

| Durability | Provides long service life and reduces maintenance costs. |

Need high-performance PTFE components for your critical fluid systems?

KINTEK specializes in manufacturing precision PTFE seals, seats, liners, and custom labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our expertise in custom fabrication ensures you get components that deliver superior chemical resistance, reliability, and longevity.

Contact KINTEK today to discuss your specific requirements and leverage our material science expertise for your next project.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What temperature range can Teflon (PTFE) balls withstand? -200°C to +260°C Performance Guide

- In which industries are Teflon (PTFE) balls commonly used? Key Applications & Benefits

- What are the advantages of PTFE balls over metals or alloys? Superior Chemical & Friction Resistance

- How do PTFE balls contribute to reduced maintenance costs? Extend Component Life and Cut Downtime

- Why are PTFE balls particularly suitable for high-performance applications? Key Properties & Selection Guide